Customized 8079 H14 0.28mm 1380mm Perforated Aluminum Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

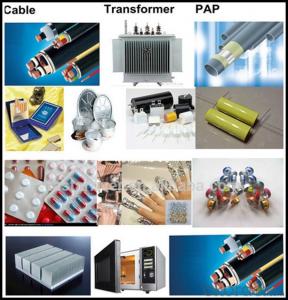

2. Application of Aluminum

(1).Interior: shutters, doors...

(2).Exterior: renovations...

(3).Advertisement: fascia, shop fronts..

3. Feature of Aluminum

Several useful derivatives of LiAlH4 are known, e.g. sodium bis(2-methoxyethoxy)dihydridoaluminate. The simplest hydride,aluminium hydride or alane, remains a laboratory curiosity. It is a polymer with the formula (AlH3)n, in contrast to the corresponding boron hydride with the formula (BH3)2.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

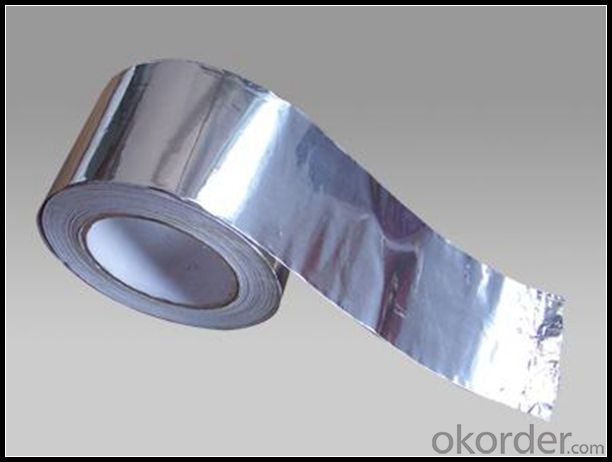

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a method to measure the thickness of aluminum siding material.

- <p>To determine the thickness of aluminum siding, you can use a digital caliper or a micrometer, which are precise measuring tools. Place the caliper or micrometer at the edge of the siding, ensuring it's perpendicular to the surface, and take a measurement. Another method is to use a magnetic thickness gauge if the siding is coated, as this tool can measure the thickness of non-magnetic coatings on magnetic metals. Always check the manufacturer's specifications for the siding as well, as they often provide thickness information.</p>

- Q: Explain the distinctions between aluminum foil and aluminum strips in a few sentences.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin, typically used for food packaging, cooking, and insulation due to its light weight and flexibility. It is also reflective, which makes it useful for cooking and baking. Aluminum strips, on the other hand, are thicker and more rigid, often used in construction, manufacturing, and automotive industries for structural support, heat exchangers, and electrical conductivity. They are not as flexible as foil and are not typically used for food-related applications.</p>

- Q: Is it possible to use aluminum strips as a material for flooring?

- <p>Aluminum strips can indeed be used for flooring, particularly in industrial or commercial settings where durability and resistance to wear are important. They are known for their strength, low maintenance, and resistance to corrosion. Aluminum strips are often used in modular flooring systems, providing a sleek and modern appearance. However, they may not be as common or suitable for residential applications due to concerns about thermal conductivity, noise, and the potential for a cold, hard feel underfoot.</p>

- Q: This question asks for a comparison between aluminum strips and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum strips are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are low-maintenance and have a long lifespan, often outlasting other materials like asphalt shingles. Compared to metal roofing, aluminum strips may be more prone to denting, but they are quieter and less likely to expand or contract with temperature changes. When compared to tile or slate, aluminum is much lighter, reducing the load on the structure and installation costs. However, it may not offer the same aesthetic appeal or insulation properties. Overall, aluminum strips are a cost-effective and eco-friendly choice for roofing, especially in areas with harsh weather conditions.</p>

- Q: The user is inquiring if it's possible to utilize recycled aluminum for their roofing project.

- <p>Yes, you can use recycled aluminum for your roofing project. Recycled aluminum is not only environmentally friendly but also cost-effective. It retains the same strength and durability as new aluminum, making it an excellent choice for roofing. It's lightweight, resistant to corrosion, and can be easily shaped and installed. Additionally, using recycled aluminum helps reduce waste and conserves natural resources. However, it's important to ensure that the recycled material meets quality standards and is sourced from a reputable supplier to guarantee its performance and longevity.</p>

- Q: Which brand of aluminium band for dry transformer?

- The domestic brand is 1060, and the state is soft. Suitable for winding.

- Q: This question asks about potential hazards or issues that might arise from using aluminum strips as flooring material.

- <p>Safety concerns related to using aluminum strips for flooring include potential slip hazards, especially in wet conditions, due to the smooth surface of aluminum. There's also a risk of electrocution if the aluminum comes into contact with electrical wiring or outlets. Additionally, aluminum can conduct heat and cold, making the floor uncomfortable underfoot in extreme temperatures. The material may also dent or scratch easily, posing a tripping hazard. Lastly, concerns about the long-term health effects of aluminum exposure, though not fully proven, should be considered.</p>

- Q: What's the difference between aluminum strip and aluminum alloy?

- The most common aluminum alloy is magnesium aluminum alloy, widely used in doors and windows frame. Light quality, high hardness, high strength and beautiful appearance. Of course, the magnesium aluminum alloy is also very many kinds, the use is more widespread. The aluminum is soft, low strength and easy to corrode. Aluminum cookers also cause excessive aluminum poisoning

- Q: This question asks about the specific uses of aluminum strips in the automotive industry.

- <p>Aluminum strips are widely used in the automotive industry due to their lightweight and corrosion-resistant properties. They are commonly used in the manufacturing of car bodies, particularly in the doors, hoods, and trunk lids, to reduce weight and improve fuel efficiency. Additionally, aluminum strips are utilized in the production of heat exchangers, radiators, and other cooling systems. They are also found in electrical wiring and connectors due to their excellent conductivity. Furthermore, aluminum strips are employed in the construction of wheels and suspension components, enhancing vehicle performance and durability.</p>

- Q: Is it possible to use aluminum strips as a roofing material in regions with cold weather conditions?

- <p>Yes, aluminum strips can be used for roofing in cold climates. Aluminum is a durable and lightweight material that is resistant to corrosion and weathering, making it suitable for various climates, including cold ones. It doesn't rust and can withstand heavy snow loads. However, it's important to consider the thermal properties of aluminum, as it conducts heat and cold efficiently, which may necessitate additional insulation to maintain the desired indoor temperature. Additionally, proper installation and underlayment are crucial to prevent moisture and heat loss.</p>

Send your message to us

Customized 8079 H14 0.28mm 1380mm Perforated Aluminum Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords