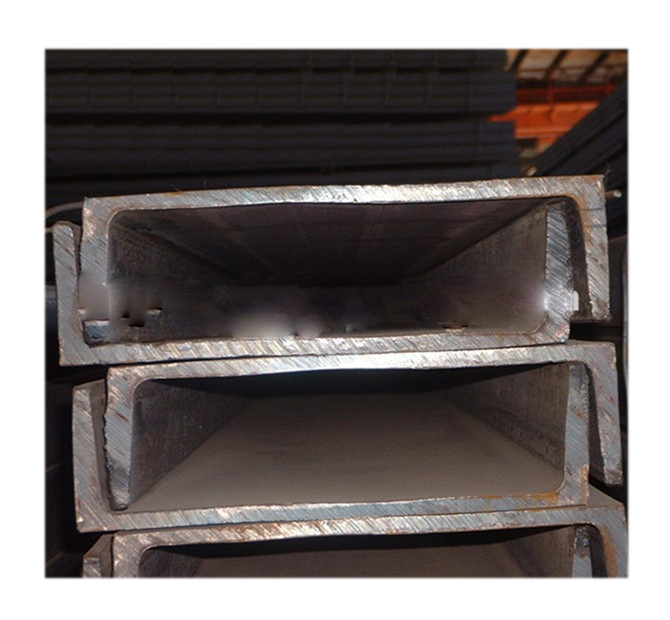

Custom Steel Channel (95mm X 8mm) Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Custom Steel Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Custom Steel Channels are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Base Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 9.0 – 14.5mm

Length: As per customer request

Max Dimensions: 90*37*4.5mm – 400*104*14.5mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

Light Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 6.4 – 8.0mm

Length: As per customer request

Max Dimensions: 50*32*4.4mm – 400*115*8.0mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What is the purpose of a steel channel?

- The purpose of a steel channel is to provide structural support and reinforcement in various construction and engineering applications. It helps distribute loads evenly and provides stability, making it useful in building frames, bridges, and other structures that require strength and durability.

- Q: Can steel channels be used in the agricultural manufacturing industry?

- Yes, steel channels can be used in the agricultural manufacturing industry. Steel channels are versatile and durable structural components that can be used for various purposes in agricultural manufacturing. They can be utilized in the construction of machinery, equipment, and infrastructure such as barns, sheds, and storage facilities. Steel channels provide strength and stability, making them suitable for supporting heavy loads and withstanding harsh environmental conditions often found in the agricultural sector. Additionally, steel channels can be easily fabricated, welded, and modified to meet specific design requirements, making them a popular choice in agricultural manufacturing.

- Q: Does anyone know how to calculate the volume of channel steel?!

- 1, check out the books on Design of cross-sectional area multiplied by the length of2, if there is in kind, called weight divided by 7.85

- Q: What are the different types of reinforcements used with steel channels?

- Steel channels can be reinforced in several ways. One common method is by embedding them in concrete structures, which increases their strength and load-bearing capacity. Steel bars or rods can also be used to reinforce the channels, either within the channel itself or along its edges, to provide extra strength and rigidity. Brackets made of steel are another option for reinforcement, connecting and stabilizing multiple channels to prevent twisting or misalignment. Welding additional steel plates or sections to the channel is another effective method, particularly for situations with high forces or dynamic loads. Additionally, reinforced steel sections like I-beams can be attached to the channels to maximize strength and load-carrying capacity. Overall, these various reinforcements enhance the channels' stability and suitability for different construction and structural applications.

- Q: How do steel channels perform in terms of wind resistance?

- Steel channels perform very well in terms of wind resistance. Their structural design and material strength allow them to withstand high wind loads without significant deformation or failure. This makes steel channels a reliable choice for applications where wind resistance is a critical factor, such as in the construction of high-rise buildings, bridges, or wind turbine towers.

- Q: The top of the elevator shaft is not pre buried hook, and now to add channel, in the channel to do hook, elevator Ii Michihiro 2500, asking the hook bearing 3 tons, the need for large channel, detailed explanation

- What is the midpoint moment by channel loadGood 30# I-beam, made of fish bellied beam

- Q: Are steel channels suitable for use in telecommunications towers?

- Yes, steel channels are suitable for use in telecommunications towers. Steel channels are known for their strength and durability, making them ideal for supporting heavy loads and withstanding extreme weather conditions. Additionally, steel channels can be easily fabricated and installed, providing a cost-effective solution for constructing telecommunications towers. They also offer excellent structural stability and can be designed to meet specific height and load requirements. Moreover, steel channels have a long lifespan and require minimal maintenance, making them a reliable choice for telecommunications infrastructure.

- Q: How do steel channels compare to other structural materials like wood or concrete?

- There are multiple advantages that steel channels have over other structural materials such as wood or concrete. To begin with, steel channels exhibit superior strength and durability when compared to wood. Steel possesses a high tensile strength, enabling it to withstand heavy loads and pressures without bending or breaking. In contrast, wood is more susceptible to warping, rotting, and insect damage over time. Furthermore, steel channels provide greater design flexibility and versatility in comparison to concrete. Steel can be easily shaped and molded into various sizes and dimensions, allowing for the creation of intricate and complex designs. Conversely, concrete necessitates formwork and curing time, limiting the range of aesthetic options available. Additionally, steel channels possess a higher level of fire resistance when compared to both wood and concrete. Steel does not burn or contribute to the propagation of flames, making it a safer choice for structural applications. Wood is highly flammable and can quickly ignite, while concrete may crack or spall under extreme heat. Moreover, steel channels have a longer lifespan and require less maintenance in contrast to wood or concrete. Steel is resistant to weathering, corrosion, and pests, thereby reducing the need for regular repairs or replacements. Conversely, wood and concrete may necessitate regular sealing, painting, or patching to prevent deterioration. Lastly, steel channels offer superior sustainability and environmental benefits when compared to wood or concrete. Steel is a highly recyclable material, and utilizing recycled steel in construction reduces the need for new extraction. Additionally, steel structures can be disassembled and reused, minimizing waste. Wood requires the harvesting of trees, which can contribute to deforestation, while concrete production has a significant carbon footprint. In conclusion, steel channels excel over wood and concrete in terms of strength, durability, design flexibility, fire resistance, lifespan, maintenance, and sustainability. These advantages establish steel channels as the preferred choice for various structural applications.

- Q: Can steel channels be used for supporting HVAC systems?

- Indeed, the utilization of steel channels for the support of HVAC systems is feasible. These steel channels are typically constructed from robust and resilient steel materials, rendering them suitable for furnishing structural support to HVAC equipment. They are frequently employed in conjunction with other supporting materials, such as brackets and hangers, in order to firmly hold and suspend HVAC units, ductwork, and piping. Steel channels offer numerous advantages when it comes to supporting HVAC systems. Primarily, they possess a substantial load-bearing capacity, guaranteeing adequate support for the weight of HVAC equipment and components. Additionally, steel channels are resistant to corrosion and can endure harsh environmental conditions, making them suitable for both indoor and outdoor applications. Moreover, steel channels provide flexibility in terms of installation. They can be effortlessly adjusted and tailored to accommodate various configurations of HVAC systems. Furthermore, steel channels can be installed using a variety of methods, including welding, bolting, or clamping, thereby offering versatility during the installation process. It is of utmost importance to ensure that the steel channels used for supporting HVAC systems are designed and installed in accordance with industry standards and local building codes. Proper engineering and design considerations, such as load calculations, seismic requirements, and thermal expansion, must be taken into account to ensure the safety and stability of the HVAC system. In summary, steel channels are a dependable and commonly employed means of supporting HVAC systems, providing strength, durability, and flexibility in installation.

- Q: What are the considerations for steel channel bracing?

- When contemplating steel channel bracing, there are several crucial factors that need to be taken into consideration. To begin with, it is of utmost importance to assess the structural requirements of the building or structure that the bracing will be supporting. This entails evaluating the loads and forces that will be exerted on the bracing system, as well as understanding the specific design codes and standards that must be adhered to. Ensuring that the bracing system can endure the expected loads and provide the required stability to the structure is absolutely essential. Secondly, careful consideration must be given to the material properties of the steel channel used for bracing. This involves evaluating the strength, stiffness, and ductility of the steel channel. Selecting a steel channel with the appropriate properties to withstand the loads and forces imposed on the bracing system is of great importance. Additionally, factors like corrosion resistance and fire resistance should also be taken into account. Another factor to consider is the design and layout of the bracing system. The spacing and arrangement of the steel channel braces should be meticulously planned to ensure sufficient support and stability. The bracing system should be designed in a manner that effectively distributes the loads and minimizes the potential for buckling or instability. Furthermore, the connections between the steel channel braces and the supporting structure should be strong and capable of efficiently transferring the loads. In addition to the design and layout, the installation of the steel channel bracing is a crucial aspect to consider. Proper installation techniques must be followed to ensure correct and secure installation of the bracing system. This involves using suitable fasteners and ensuring that the bracing is aligned and connected properly. Lastly, it is important to take into account any potential limitations or restrictions that may impact the steel channel bracing. This could include factors such as available space for installation, access for maintenance or repair, or any specific environmental conditions that could affect the performance of the bracing system. Overall, by carefully considering the structural requirements, material properties, design and layout, installation techniques, and any limitations or restrictions, one can ensure that the steel channel bracing is effective and provides the necessary support and stability for the structure.

Send your message to us

Custom Steel Channel (95mm X 8mm) Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords