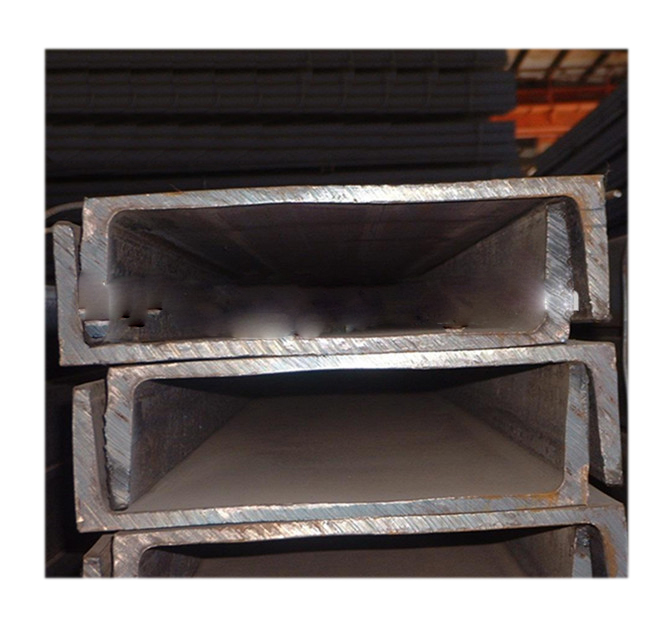

Custom Steel Channel (91mm X 8mm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Custom Steel Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Custom Steel Channels are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Base Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 9.0 – 14.5mm

Length: As per customer request

Max Dimensions: 90*37*4.5mm – 400*104*14.5mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

Light Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 6.4 – 8.0mm

Length: As per customer request

Max Dimensions: 50*32*4.4mm – 400*115*8.0mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the different connection methods for steel channels?

- There are several different connection methods for steel channels, including welding, bolting, and using connection plates or brackets. These methods are used to securely join steel channels together in various structural and construction applications.

- Q: What are the factors that affect the price of steel channels?

- The price of steel channels can be influenced by various factors. Let's explore some of these factors: 1. Raw material costs play a significant role in determining the price of steel channels. The cost of materials like steel, iron ore, and coal directly affects the manufacturing cost of steel channels. Fluctuations in these raw material prices can, in turn, impact the final price of the channels. 2. Supply and demand dynamics also have an impact on steel channel prices. When demand for steel channels is high and the supply is limited, prices tend to rise. Conversely, if demand is low and there is excess supply, prices are likely to decrease. 3. Manufacturing and processing costs, including expenses related to labor, energy, and equipment, can influence the price of steel channels. Higher manufacturing costs may result in higher prices for the channels. 4. The level of competition among steel channel manufacturers can also affect prices. When multiple producers offer similar products, they may engage in price competition to attract customers, leading to lower prices. On the other hand, if there are fewer suppliers or if they offer unique products, prices may be higher. 5. Transportation and logistics costs can impact the final price of steel channels. Factors such as fuel prices, shipping distances, and transportation infrastructure all contribute to transportation costs, which can be passed on to the buyer. 6. Government regulations and tariffs are another factor that can influence steel channel prices. Trade policies, import duties, and government regulations can increase the price of imported steel channels, while subsidies or support from the government can lead to lower prices. 7. Economic conditions, both globally and domestically, have an impact on steel channel prices. Economic growth, inflation, and currency exchange rates can all influence the cost of steel channels. It is important to understand that these factors are interconnected and can vary depending on market dynamics and location. Therefore, buyers and sellers in the steel channel industry must consider these factors and their potential impact.

- Q: Can steel channels be used in high-temperature environments?

- Yes, steel channels can be used in high-temperature environments. Steel has excellent heat resistance properties and can withstand high temperatures without losing its structural integrity. However, the specific type of steel used and its alloy composition should be carefully selected to ensure optimal performance and prevent any potential issues such as corrosion or deformation.

- Q: What's the difference between channel type 25a#, 25b# and 25c#?

- Channel type 25a#, 25b#, 25c# is to indicate "waist height of the same" channel, but its leg width and waist thickness is different, so you need to add a, B, C to the right of the model to be distinguished. For example, 25a# means 250*78*7. 25b# stands for 250*80*9.

- Q: How do steel channels compare to other structural materials like wood or aluminum?

- Steel channels have several advantages over other structural materials like wood or aluminum. Firstly, steel channels are much stronger and more durable than wood, making them suitable for heavy-duty applications. Additionally, steel channels have a higher resistance to fire, pests, and decay compared to wood. Compared to aluminum, steel channels have a higher load-bearing capacity, making them more suitable for supporting heavy loads. Moreover, steel channels offer better resistance to corrosion and extreme weather conditions. Overall, steel channels are a preferred choice for structural applications due to their superior strength, durability, and resistance to various environmental factors.

- Q: How do steel channels contribute to the overall flexibility of a structure?

- The overall flexibility of a structure is improved through the utilization of steel channels in multiple ways. To begin with, they contribute to the structure's stability by offering extra support and reinforcement, enabling the more efficient distribution of loads and forces. This results in the prevention of excessive deflections and deformations. What's more, steel channels possess a high degree of versatility and can be easily customized and adjusted to meet specific project requirements. Their open shape allows for the insertion of other structural elements, like beams or columns, which further enhances the structure's flexibility. This adaptability permits engineers to design structures with varying span lengths and load capacities, making them suitable for a wide range of applications. In addition, steel channels possess a high strength-to-weight ratio, meaning they can withstand significant loads while remaining relatively lightweight. This characteristic enables the construction of more flexible and cost-effective structures, as the weight of the channels does not excessively contribute to the overall load on the structure. Furthermore, steel channels can be easily interconnected and joined together using bolts, welding, or other methods. This simplifies the construction process and allows for the inclusion of different design elements, such as cantilevers or bracing systems, which can further enhance the structure's flexibility and overall performance. In conclusion, steel channels play a vital role in enhancing the flexibility of structures by providing additional support, adaptability, and strength. Their efficient load distribution, ability to accommodate various design requirements, and capacity to withstand significant forces make them a valuable component in the construction industry.

- Q: How do steel channels perform in corrosive chemical environments?

- Steel channels generally perform well in corrosive chemical environments due to their high resistance to corrosion. This is primarily because steel, especially stainless steel, forms a protective oxide layer that prevents or slows down the corrosion process. However, the exact performance can vary depending on the specific chemical environment and concentration. It is important to consider the corrosive properties of the chemicals and consult with experts or engineers to select the appropriate type and grade of steel channel for optimal performance and longevity in corrosive chemical environments.

- Q: Can steel channels be used as support beams?

- Yes, steel channels can be used as support beams. Steel channels, also known as C-channels or U-channels, are commonly used in construction for their strength and structural stability. They are specifically designed to provide support and stability, making them suitable for use as support beams. Steel channels are often used in various applications such as building frames, bridges, and industrial structures, where their load-bearing capabilities are crucial. They offer high strength-to-weight ratio, durability, and resistance to bending and twisting forces, making them an ideal choice for supporting heavy loads and distributing weight effectively. Therefore, steel channels can be confidently used as support beams in various construction projects.

- Q: Can steel channels be used for window and door frames?

- Yes, steel channels can be used for window and door frames. Steel channels provide strength, durability, and stability, making them suitable for supporting the weight and ensuring the stability of window and door structures. They can also be customized to fit specific dimensions and shapes, making them a versatile choice for window and door frame construction.

- Q: Use two long five meters of 10# channel steel load-bearing frame, the maximum load is?

- 8 channel steel and 40*60 square steel tube, which is good in bending strength?

Send your message to us

Custom Steel Channel (91mm X 8mm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords