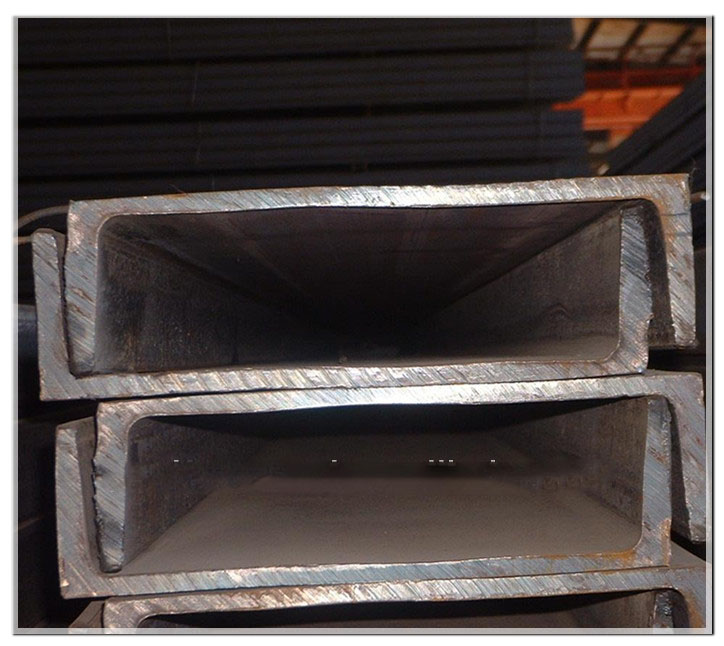

Custom Steel Channel (90mm X 9mm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Custom Steel Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Custom Steel Channels are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Base Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 9.0 – 14.5mm

Length: As per customer request

Max Dimensions: 90*37*4.5mm – 400*104*14.5mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

Light Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 6.4 – 8.0mm

Length: As per customer request

Max Dimensions: 50*32*4.4mm – 400*115*8.0mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the logistics and warehousing equipment? The more, the better

- Plastic tray tray, wooden pallets, steel pallets, storage cage, tchouk frame, logistics trolley, forklift cage, shelves of light, medium, heavy.

- Q: What are the types of logistics equipment?

- According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.

- Q: How to do the warehouse logistics supervisor?

- Make reasonable operation procedure. After the above of a warehouse, goods storage and storage function, the amount of work and other warehouse problems often appear to understand, to need the operation is carried out in the warehouse and work out a reasonable process.

- Q: What are the problems in e-commerce, logistics and warehousing?

- The development of e-commerce depends to a large extent on the logistics enterprises to maintain high quality of service and flexibility, and control and reduce the cost of logistics. But in the logistics industry, some enterprises are empty of vehicles, idle warehouses, while many enterprises are looking for vehicles and warehouses. This shows that the social freight and warehousing resources are not short, and the lack of integration resources between enterprises. Therefore, the application of logistics technology now, the electronic commerce logistics enterprises scattered alliance, forming a service network, is the best way to reduce the cost of logistics and distribution, e-commerce to improve the level of development of e-commerce logistics.

- Q: What's the sea cucumber logistics equipment?

- Sea cucumber is a kind of spiny animal that grows on the bottom rock of the sea or between seaweeds. It is named after its "warm, warm and sufficient ginseng". Sea cucumber as a rarity, its nutritional value is high, the treatment effect of magic, has long been recognized and praised.

- Q: What are the categories of logistics?

- The main focus of traditional logistics is warehousing and inventory management and delivery, and sometimes the main focus is on warehousing and transportation to make up for differences in time and space. Integrated logistics not only provide transportation services, including many coordination of the entire supply chain management, such as management of transportation, warehousing department and some other distributors, including order processing, procurement etc.. Because much effort is put on supply chain management, more responsibility and more complex management, which is different from traditional logistics.

- Q: What does the storage equipment mainly consist of?

- Warehousing equipment mainly consists of:1, a variety of specialized warehouses;2. Facilities in the warehouse;3, all kinds of ancillary equipment, such as: explosion protection, fire fighting, metering, temperature measurement, ventilation, information management, etc..

- Q: What are the main facilities and equipment in the warehouse?

- Logistics warehousing equipment is divided into two major categories: logistics equipment, storage equipment.

- Q: What role does warehousing play in logistics?

- Warehousing is, first and foremost, a logistics activity, or logistics activity is the essential attribute of warehousing. Warehousing is not a production, not a transaction, but one of the logistics activities for production and transaction services. This shows that warehousing is only one of the logistics activities, logistics and other activities, warehousing should be integrated into the entire logistics system, should be associated with other logistics activities, and coordination. This is a significant difference from the past "warehouse management".

- Q: The disadvantages of traditional warehousing and the advantages of modern warehousing

- The socialization of warehouse management is not high. Even with the same enterprise, some internal logistics resources can not be shared. As the storage management is backward, the utilization ratio of storage facilities resources is less than 40%, which leads to the low efficiency of logistics

Send your message to us

Custom Steel Channel (90mm X 9mm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords