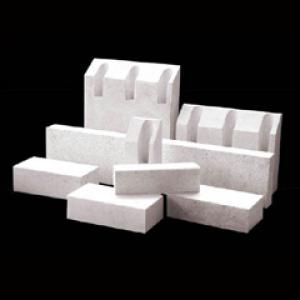

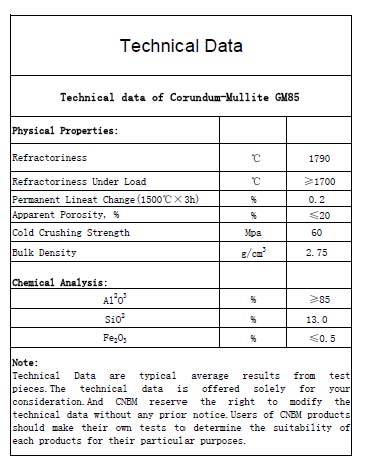

Corundum-Mullite Brick GM85

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Ton m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Corundum-Mullite Brick GM85

CMAX corundum-mullite bricks use the high-purity fused corundum as the main raw materials, the application of advanced technology to add superfine powder, after mixing, drying, forming, in the high temperature shuttle kiln fired from. Widely used in residue gasification, ammonia secondary reformer, carbon black reactor and refractory furnace and other equipment.

Feature of Corundum-Mullite Brick GM85

Good thermal shock resistance

Low thermal conductivity

High strength

Good erosion resistance

Excellent high temperature mechanics

Excellent chemical corrosion resistance.

Application of Corundum-Mullite Brick GM85

Corundum Mullite Bricks are mainly used in EAF roof industrial furnace lining, other furnace glass furnace, glass ceramic kiln and tunnel kiln. Also they can be used in iron making industries, like laying ceramic, taphole of blast furnace and tuyere. It can protect the bottom of blast furnace for longlife using.

- Q: Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum. Highrefractoriness, up to over 1790 DEG C 1600. Load softening start temperature to 1700 DEG C. Compressive strength at room temperature is 70 ~ 260MPa.. The thermal shock resistance of sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or alum clay as binder, forming and sintering made of fused mullite bricks with high alumina and bauxite, refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite than sintered mullite, thermal resistance Shock resistance than sintered products. The uniformity of content in alumina mainly depends on their high temperature properties and mullite phase and glass distribution. Mainly used in blast furnace, furnace top and bottom furnace, glass furnace regenerator, sintering kiln, petroleum cracking system dead lining.

- Q: What are the properties of corundum mullite?

- Heavy material has good compactness, high compressive strength, resistance to various corrosive gases, good thermal shock resistance, good thermal conductivity and wear resistance.

- Q: Corrosion mechanism of iron on refractory materials

- Iron oxide can not be used as refractory,

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more

- Q: 2000 degree of high temperature materials, which belong to high temperature insulation materials?

- Magnesium compounds, ceramics, mica, corundum, silicon, graphite, titanium alloy, diamond, tungsten, silicon dioxide, silicon carbide, carbon, copper oxide, iron oxide, iron, manganese, lightweight mullite corundum brick, high aluminum brick lightweight clay brick, alumina hollow ball1) rock wool board: thermal conductivity 0.041-0.045, fire retardant, fire resistance, temperature absorption, insulation effect is poor.(2) glass wool: construction is simple, free cutting. Antibacterial, mildew proof, aging resistance, corrosion resistance, and guarantee the healthy environment. Low hygroscopicity and stable physical properties.

- Q: What material is heat insulated and not afraid of fire?

- Industrial production of perlite as insulation materials began in the United States in 1964Arizona, while China's expanded perlite began production in the late 60s. Expanded perlite includes perlite and pineRock and obsidian (three of which are close to the water content), due to the high temperature in 1000-1300C0, the volume of rapid expansion of 4 - 30 times, so collectively referred to as expanded perlite. Its characteristics are: low thermal conductivity, fire resistance and sound insulation performance is good, non-toxic, cheap, but have very strong water absorption, thermal conductivity due to water is much higher than that of pearlite, water will cause its insulation performance degradation, inorganic porous material, low strength, easy to break; therefore in thermal insulation applications when the need to enhance the hydrophobic and expanded perlite.

- Q: What are the high temperature insulation materials?

- If there is atmosphere protection, then graphite is a more powerful material. Melting point 3850 degrees Oh, almost all ultra high temperature kiln, can be protected by atmosphere, all with graphite material.

- Q: What kind of refractory material is used in the hearth of reverberatory furnace?

- The alumina fiber has a maximum resistance of 1700 degrees, and the zirconium fiber is generally 1700 to 2200 degrees

- Q: What material is good for refractory bricks?

- Is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Corundum-Mullite Brick GM85

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Ton m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords