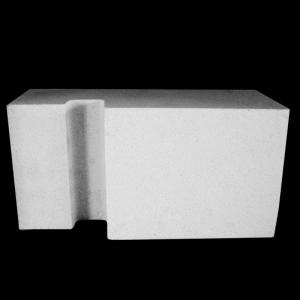

Corundum-Mullite Brick GM84

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Ton m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

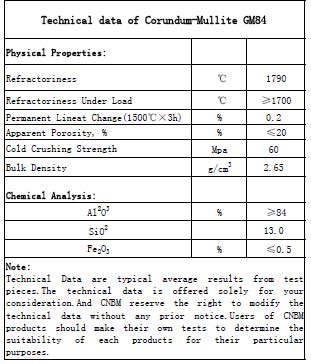

General Information of Corundum-Mullite Brick GM84

CMAX corundum-mullite bricks use the high-purity fused corundum as the main raw materials, the application of advanced technology to add superfine powder, after mixing, drying, forming, in the high temperature shuttle kiln fired from. Widely used in residue gasification, ammonia secondary reformer, carbon black reactor and refractory furnace and other equipment.

Feature of Corundum-Mullite Brick GM84

Good thermal shock resistance

Low thermal conductivity

High strength

Good erosion resistance

Excellent high temperature mechanics

Excellent chemical corrosion resistance.

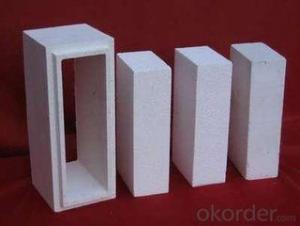

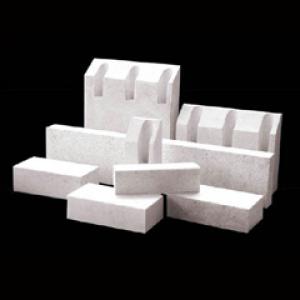

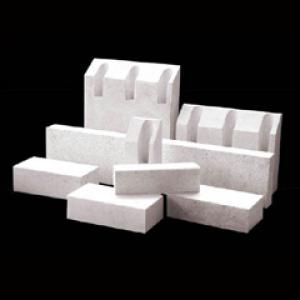

Application of Corundum-Mullite Brick GM84

Corundum Mullite Bricks are mainly used in EAF roof industrial furnace lining, other furnace glass furnace, glass ceramic kiln and tunnel kiln. Also they can be used in iron making industries, like laying ceramic, taphole of blast furnace and tuyere. It can protect the bottom of blast furnace for longlife using.

- Q: Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum. Highrefractoriness, up to over 1790 DEG C 1600. Load softening start temperature to 1700 DEG C. Compressive strength at room temperature is 70 ~ 260MPa.. The thermal shock resistance of sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or alum clay as binder, forming and sintering made of fused mullite bricks with high alumina and bauxite, refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite than sintered mullite, thermal resistance Shock resistance than sintered products. The uniformity of content in alumina mainly depends on their high temperature properties and mullite phase and glass distribution. Mainly used in blast furnace, furnace top and bottom furnace, glass furnace regenerator, sintering kiln, petroleum cracking system dead lining.

- Q: What are the properties of corundum mullite?

- Heavy material has good compactness, high compressive strength, resistance to various corrosive gases, good thermal shock resistance, good thermal conductivity and wear resistance.

- Q: Corrosion mechanism of iron on refractory materials

- But you can do refractory additives. Iron oxide paints are widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: 2000 degree of high temperature materials, which belong to high temperature insulation materials?

- What can withstand 2000 degree high temperature materials on the market? What are the materials belong to high temperature materials? High temperature insulation material the most common are the following: calcium silicate shell, aluminum silicate cotton felt, glass surface, diatomite, vermiculite, foamed cement etc.. Among them, the first three are the most common, especially the aluminum silicate cotton felt, which can withstand 650 degrees of high temperature.

- Q: What material is heat insulated and not afraid of fire?

- Foam as a kind of important organic insulation materials, there are two kinds of polystyrene and polyurethane foam, which was published in 30s, the production in our country began in late 50s and 60s, which is characterized by the effect of thermal insulation performance, light weight, sound absorption properties, but the organic materials and brick wall with construction is difficult. Need the polystyrene foam plate is adhered in the walls with special binder and coupling agent, after a plurality of process, the construction is very complex. Moreover, foam plastic products have poor aging resistance, low service life, and waste materials can not degrade and cause white pollution.

- Q: What are the high temperature insulation materials?

- The most thermal insulation is a variety of cotton fiber insulation, but the temperature is not very high. Alumina polycrystalline fiber cotton, about 1600 degrees, mullite polycrystal, mixed polycrystal, lower temperature. Zirconia material is said to be capable of high temperature because zirconia has a melting point of 2700 degrees, 700 degrees higher than alumina. But it's not used. It's not clear.

- Q: What kind of refractory material is used in the hearth of reverberatory furnace?

- 1400 degrees below can use clay brick, high alumina brick; 1400 to 1700 can use mullite bricks, heavy corundum brick; more than 1700 can use zirconia brick, such as zirconia brick

- Q: What material is good for refractory bricks?

- Is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Corundum-Mullite Brick GM84

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Ton m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords