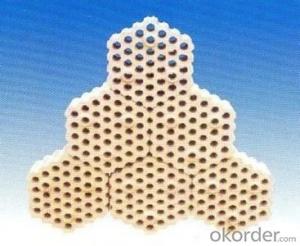

High-Quality Corundum Brick Castable Corundum CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

white corundum/alundum F46#:

1.High purity of 99%min

2.Manufacturer,not trading company

3.Experience-15years

Description:

white corundum/alundum abrasives, a kind of high-grade refractories, was made from the high quality alumina by melting above 2000 in the electric arc furnace and cooling. It is white with the main crystal phase

alpha-Al2O3. The white alumina produced in titling electric arc furnace has the advantage of high bulk density and low porosity and the volume stability and thermal shock resistance can be improved.

The chemical and physical analysis for white corumdum/alundum:

Chemical Analysis | Typical | Specification |

Al2O3 | 99.55 % | 99.50(min) |

SiO2 | 0.04 % | - |

Fe2O3 | 0.04 % | - |

CaO | 0.03 % | - |

MgO | 0.02 % | - |

Na2O | 0.22 % | - |

K2O | 0.01 % | - |

Physical properties | Tipycal | Specification |

Bulk density | 1.53-1.99g/cm3 | 1.75-1.95g/cm3 |

Bulk Density | 3.95g/cm3 | 3.90g/cm3 |

Morse hardness | 9 |

|

Micro hardness | 21600-22600kg/mm3 |

|

Mineralogy | Predominantly Alpha Alumina | |

- Q: Application of electric high temperature regulating valve?

- Now, the definition of refractories has not only depended on the degree of refractoriness is more than 1580 degrees celsius. At present, refractory materials refer to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: What refractory materials are adopted in each part of the blast furnace?

- The lower part of the shaft due to high temperature and dust by scouring and alkali metal vapor erosion, so the requirements for the slag resistance, alkali resistance and high temperature resistance, wear resistance of high quality clay brick, high alumina brick, carborundum brick or corundum brick. Belly temperature reaches 1400~1600, and slag, steam erosion, erosion and corrosion is strong, therefore, the silicon carbide reaction bonded silicon carbide brick.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: What kind of refractory material will be used in the glass kiln?

- It has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

- Q: What can zirconium sponge do for those industries?

- Zirconium metal, also known as sponge zirconium, silver gray metal, the appearance of steel, shiny; melting point 1852 points, sub points, boiling point 4377 density 6.49. Zirconium is easy to absorb hydrogen, nitrogen and oxygen; zirconium has a strong affinity for oxygen; at 1000 DEG C oxygen dissolved in zirconium can make its volume increase significantly. Zirconium is relatively stable in the air; powder zirconium is easy to burn; fine zirconium wires can be ignited by matches; at high temperatures they can be combined directly with dissolved oxygen, nitrogen and hydrogen.

Send your message to us

High-Quality Corundum Brick Castable Corundum CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches