aluminium roofing sheet roll forming machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium roofing sheet making machine

1.. Processing technique and deployment

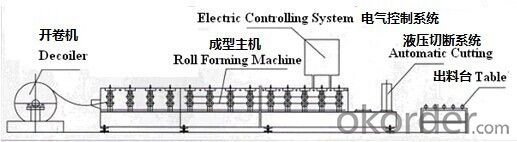

Flow chart : Decoiler-- Roll Forming--PLC System—Hydraulic System –Pressing --Cutting —Output Table

No. | Name | Unit | Qty |

1 | Decoiler | set | 1 |

2 | Main Machine for roll forming | set | 1 |

3 | Control System(PLC) | set | 1 |

4 | Pressing System | set | 1 |

5 | Cutting System | set | 1 |

6 | Output Table | set | 1 |

Processing material | colored steel plate, galvanized plate, or aluminum plate |

Material thickness | 0.3---0.8mm |

Material hardness | 195 mpa---350 mpa |

Forming speed | 8-12m/min |

Working speed | 5-8m/min |

Usage | It is used to support the steel coil and uncoil it in a turnable way. Passive uncoil pulled by roll forming system

|

Loading capacity | 5T |

Uncoiling width | 1250 |

Inner diameter | 450-550mm |

Entry Beach

Usage:Put the raw material(steel plate) through the beach to manufacture and process,

it can guarantee that the products are neat, parallel and everything is uniformity.

Please refer to the equipment regulation to know the function of locate angle iron.

Main parameters of aluminium roofing sheet making machine | ||

1 | Length of the main part | about 10500*1650*1500mm |

2 | Weight of main part | 7.5T |

3 | Voltage | 380V/50HZ 3Phase |

4 | Roller fixer | middle plate |

5 | Frame | 350H steel |

6 | Drive mode | chain |

7 | Material of rollers | 45#steel, surface hard chromium plating |

8 | Material of shafts | 45#steel |

9 | Diameter of shafts | φ 80mm |

10 | Number of rollers | 18 rollers |

11 | Main power | 5.5kw |

12 | Material of mould | Cr12 quenched |

13 | Power supply | hydraulic power |

cutting device

The cutting blade controled by the hydraulic system

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades | Cr12 quenched |

Power supply | hydraulic power |

Components | It contains one set of blade, one hydraulic tank and one cutter machine. |

Power | 5.5KW |

the machine naked in the container or packing as your required.

Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

Delivery: within 45 working days after receipt of deposit

Guarantee: One year, and we will provide the technical support for the whole life.

- Q: What steps are required during the installation of the cement tile machine?

- Hydraulic station installation: the hydraulic station on the left side of the host 1.5 meters (from front to back), the tubing must be tightened, the cooler connected to the cooling water.

- Q: Analysis on the Problems of Cement Shade Machine

- construction process to meet the requirements. Discoloration of the substrate in the humidity is too high, water-soluble salt crystals in the surface weathering; substrate containing alkaline, infiltration of alkaline weak paint or paint film;

- Q: The processing method of the tile machine

- Watt plate and tile gap is too large, generally should be 1 ~ 5mm. The gap is too large will make the tile broken, the gap will be bad top tile. The tile tray is raised too fast or jitter. Adjust the corresponding air valve can be.

- Q: What are the advantages of cement tile machine?

- A machine multi-purpose, tile mode switch fast, fool-type operation, low power, CNC molding. Unique design, multi-functional hydraulic molding, user-friendly interface operation, advanced and reasonable layout, to fill the gaps in the domestic.

Send your message to us

aluminium roofing sheet roll forming machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords