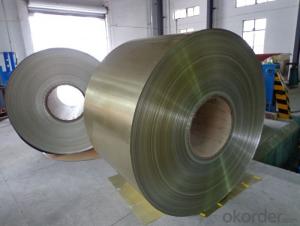

Copper Colored Mill Finished and Color Coated Aluminum Coil for Display Platforms

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished And Color Coated Aluminium Coil For Display Platforms

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Are there any limitations on the coil flatness of aluminum coils?

- Yes, there are limitations on the coil flatness of aluminum coils. The flatness is influenced by factors such as the thickness, temper, and alloy of the aluminum, as well as the manufacturing process. While manufacturers strive for optimal flatness, it is important to note that perfect flatness is difficult to achieve.

- Q: so i've been using natural deodorants that don't have aluminum, but they only work for a little while. i've heard that aluminum may cause Alzheimer's, and i have a history of Alzheimer's. do you know of any web sights that can confirm/deny this? or if you know of any deodorants that work really well that don't have aluminum! this is really getting annoying

- I okorder , not an antiperspirant. So it doesn't block the sweat glands and until my body adjusted I would say that I sweated more. However the odour was eliminated effectively. The product is a solid stick of deodorant and the first one lasted me 6 months! My wife likes it because she can put it on straight after shaving and it leaves her armpits lovely and soft and smooth.

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing coils are frequently used in various types of roofs, including residential, commercial, and industrial buildings. They offer excellent protection against extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, aluminum coils are energy-efficient as they can reflect heat from the sun, helping to keep the building cool and reducing energy costs. Overall, aluminum coils provide a reliable and long-lasting roofing solution.

- Q: How do aluminum coils contribute to sustainable manufacturing?

- Aluminum coils contribute significantly to sustainable manufacturing in various ways. Firstly, aluminum is a highly recyclable material, and the use of aluminum coils promotes a closed-loop recycling system. These coils can be easily melted down and reused without losing their original properties, reducing the need for new raw materials and minimizing the environmental impact of mining and extraction. Additionally, aluminum coils are lightweight, which reduces energy consumption during transportation. Their lightweight nature makes them more fuel-efficient to transport, resulting in lower greenhouse gas emissions. This not only reduces the carbon footprint but also saves costs associated with transportation. Moreover, aluminum has excellent corrosion resistance properties, which makes it durable and long-lasting. This durability reduces the need for frequent replacements, leading to less waste generation. It also extends the lifespan of products that use aluminum coils, reducing overall resource consumption and minimizing environmental strain. Furthermore, the use of aluminum coils in manufacturing processes promotes energy efficiency. Aluminum has high thermal conductivity, meaning it can efficiently transfer and dissipate heat, resulting in reduced energy consumption during various manufacturing operations. This energy efficiency translates into lower energy costs and reduced greenhouse gas emissions. Lastly, aluminum is non-toxic and does not release harmful substances during its lifecycle. This ensures the safety of workers, consumers, and the environment. The absence of toxic materials also simplifies the recycling process, making it easier and more environmentally friendly. In conclusion, aluminum coils contribute to sustainable manufacturing through their recyclability, lightweight nature, durability, energy efficiency, and non-toxic properties. By incorporating aluminum coils into manufacturing processes, companies can reduce their environmental impact, conserve resources, and promote a more sustainable future.

- Q: metals an aluminum can is made of, cast aluminum, 6160 aluminum, sheet aluminum

- the aluminum is alloyed with various metals to change the characteristics of the aluminum the link below shows a table showing the various chemical/metals added to aluminum to make different alloys

- Q: This question asks about the impact of aluminum coils on the quality of food when it is stored. It seeks to understand if there are any changes in the food's properties due to the presence of aluminum coils.

- <p>Aluminum coils themselves do not directly affect the quality of food during storage. They are often used in the packaging industry for their excellent barrier properties against light, oxygen, and moisture, which can help preserve the freshness and quality of food by preventing spoilage and oxidation. However, it's important to note that aluminum does not interact with food in a way that alters its taste or nutritional content. Any potential health concerns related to aluminum exposure are more associated with the manufacturing process and not with the storage of food in aluminum-coiled packaging.</p>

- Q: What are the various dimensions and specifications of aluminum coils available in the market?

- <p>Aluminum coils come in various sizes and specifications to cater to different industrial needs. Common sizes include thicknesses ranging from 0.005 to 0.5 inches (0.13 to 12.7 mm), widths from 1 to 72 inches (25 to 1829 mm), and lengths from 10 to 6000 feet (3 to 1829 meters). The specific dimensions can vary based on the manufacturer and the application, such as construction, automotive, or packaging. It's important to consult with suppliers for the exact sizes available for a particular project or application.</p>

- Q: This question asks for the methods and practices to keep aluminum coil in good condition and prevent damage or corrosion.

- <p>To maintain aluminum coil, follow these steps: Store the coil in a dry, clean environment to prevent moisture and dirt from causing rust. Keep it away from corrosive substances. Regularly inspect the coil for any signs of damage or corrosion, and address any issues promptly. Handle the coil carefully to avoid scratches or dents. Use protective coverings during transportation to prevent damage. Keep records of the coil's condition and maintenance history to track its performance over time. Regular maintenance will help extend the life of the aluminum coil and maintain its quality.</p>

- Q: Does anyone know if aluminum skateboards are good?

- aluminum skateboards are ok if your just olling and playing around on them. but if your a real skater you'll probably want to get a real one.

- Q: What is the typical lead time for ordering aluminum coils?

- The lead time for ordering aluminum coils can vary depending on factors such as the supplier, quantity ordered, and current market conditions. Typically, lead times for aluminum coils can range from a few weeks to several months. If the supplier has the coils readily available in their stock, the lead time can be relatively short, usually around 2-4 weeks. This is the case when the supplier consistently maintains inventory and has the desired specifications and quantities ready for immediate shipment. However, if the coils need to be customized or if the supplier lacks sufficient stock, the lead time can be longer. Customizing aluminum coils may require additional processing time, such as rolling, annealing, or coating, which can extend the lead time by a few weeks or even months. Moreover, lead times can be influenced by market conditions and demand fluctuations. When there is high demand or disruptions in the supply chain, lead times may increase due to limited availability of raw materials or production capacity. For a more accurate estimate of the lead time for ordering aluminum coils, it is advisable to directly contact the specific supplier or manufacturer. They can provide detailed information based on their current inventory, production capabilities, and any other factors that may impact lead times.

Send your message to us

Copper Colored Mill Finished and Color Coated Aluminum Coil for Display Platforms

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords