Construction Hoist SC270/270 Heavy Lifting Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT, LC or Cash

- Min Order Qty:

- 1 unit

- Supply Capability:

- 28 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Rated load(kg):2*2700 Lifting Speed(m/min):0~45 Motor Power(kw): 2*3*18.5

Safety Device: 2*SAJ50-1.4 Cage: Double Counterweight: No

Certification: CE,ISO Place of Origin: China Model Number: SC270/SC270

Packaging & Delivery of Building Hoist

Packaging Detail: Nude in 40HQ container Shipping Time : About 30 days

Main Parts of Building Hoist

● Adopts the most advanced VF (Siemens, Schineider, Yaskawa) speed control device and microcomputer programmable logic controller.

● China famoust brand motor and Nord motor are both available

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● Standard cage size is 3.2x2.5x1.5m, customized cage size can be met.

● Lifting speed can be divided into three level low, medium and high. The speed selection depends on the height of building.

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist photoes

CMAX Building Hoist

Hot Galvanized Mast Section

Electrical Cabinet

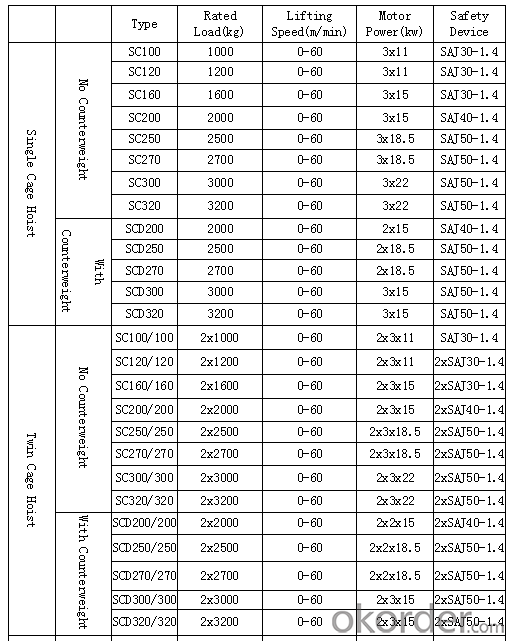

Specifiction

FAQ of Construction Hoist

Q: What is the building hoist used for?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the components of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: How do we define the construction hoist?

A: Take SC270/270 for example: “SC” stands for rack and pinion hoist, “270/270” stands for double cage and capacity

is 2.7 tons per cage. “SC270” stands for single cage and capacity is 2.7 tons.

Q: Can we have some reference of CMAX hoist abroad?

A: Sure, we have customers worldwide such as southeast Asia, Middle east, Russia. Reference list is available.

- Q: This question asks for the different types of lifting equipment that can be compatible with a building hoist.

- <p>Building hoists are commonly used in construction projects to lift materials and personnel. Compatible lifting equipment includes various types of hooks, slings, and shackles for securing loads; lifting beams for heavier or bulkier items; and specialized attachments like pallet forks for moving palletized loads. It's crucial to use lifting equipment that is rated for the weight of the load and compatible with the hoist's specifications to ensure safety and efficiency.</p>

- Q: This question asks for a comparison between electric and pneumatic building hoists, highlighting their distinct features and operational differences.

- <p>Electric building hoists are powered by electricity and are known for their high lifting capacity, speed, and efficiency. They are suitable for heavy-duty applications and can be automated for continuous operation. Pneumatic hoists, on the other hand, use compressed air to generate lifting force. They are quieter, require less maintenance, and are safer in environments where electrical sparks could be hazardous. However, they have lower lifting capacities and are generally slower compared to electric hoists. Pneumatic hoists are also more suitable for applications requiring precise control over the load.</p>

- Q: This question asks for an explanation of the working mechanism of a building hoist, which is a device used in construction to lift materials and workers.

- <p>A building hoist, also known as a construction hoist or personnel/material hoist, is a temporary lifting device used in construction projects to transport workers and materials vertically within a building. It typically consists of a tower, a cage, a drive mechanism, and a control system. The tower is attached to the building's structure, and the cage is where people or materials are loaded. The drive mechanism, often powered by an electric motor, raises and lowers the cage along the tower. The control system manages the movement, ensuring safety features like speed control and emergency stops are in place. The hoist operates within a guide rail system, which keeps it aligned as it moves up and down the building's height.</p>

- Q: What measures can be taken to guarantee the smooth and reliable operation of a building hoist during lifting?

- <p>To ensure the smooth and reliable operation of a building hoist, regular maintenance and inspection are crucial. This includes checking the hoist's mechanical components for wear and tear, ensuring the electrical systems are functioning correctly, and verifying that all safety mechanisms are in place and operational. Additionally, proper lubrication of moving parts, adherence to load limits, and operator training on safety protocols are essential. It's also important to use hoists that meet safety standards and to avoid overloading. Regularly updating and upgrading the hoist system can also enhance reliability and safety.</p>

- Q: Why do you ask the construction elevator to be a certain distance from the structure? Is very close to if not you can not bother to do delivery channel security protection or something, out of the elevator out directly, and attachment should be able to get more easily, to solve. Thank you very much!!

- The country stipulates that the distance between the moving parts of the elevator and the building and the fixed construction equipment should not be less than 0.25 meters. It's mainly about safety.

- Q: This question asks about the various types of control systems used in building hoists, which are essential for the safe and efficient operation of construction elevators.

- <p>There are several types of building hoist control systems that ensure the safe and efficient operation of construction elevators. These include: 1. Manual Control Systems: Operated by a human operator who controls the hoist's movement. 2. Semi-Automatic Control Systems: Combine manual operation with some automated features, like automatic level selection. 3. Fully Automatic Control Systems: Completely automated, with the hoist moving between floors without manual intervention. 4. Microprocessor-Based Control Systems: Utilize advanced microprocessors for precise control and monitoring. 5. PLC-Based Control Systems: Use Programmable Logic Controllers for robust and customizable control. 6. Wireless Control Systems: Enable remote operation and monitoring of the hoist. Each system has its advantages and is chosen based on specific project requirements, safety standards, and budget considerations.</p>

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: How to adjust the weight limit of the construction elevator

- It's very simple, there's a couple of buttons down here, okay

- Q: This question asks for guidance on selecting the appropriate lifting equipment based on specific requirements.

- <p>Choosing the right type of lifting equipment involves assessing several factors: the weight and size of the load, the environment in which the lifting will occur, and the specific tasks to be performed. Consider the load capacity required and ensure the equipment can handle the heaviest item you need to lift. Evaluate the space constraints and accessibility of the lifting area. Select equipment that is safe for the environment, such as explosion-proof models for hazardous areas. Consider the need for mobility and whether the equipment should be portable or fixed. Finally, consult with equipment manufacturers or industry experts to ensure you choose equipment that meets all safety standards and is suitable for your specific lifting needs.</p>

- Q: Construction site construction elevator and tower crane, which unit security check and acceptance?

- Different but most likely is the construction elevator

Send your message to us

Construction Hoist SC270/270 Heavy Lifting Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT, LC or Cash

- Min Order Qty:

- 1 unit

- Supply Capability:

- 28 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords