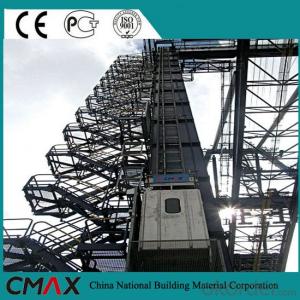

Construction Hoist Building Lifter SCD270/270

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

1.Feature: Construction Hoist

2.Payload(kg):2*2700

3.Lifting Speed(m/min):33

4.Motor Power(kw): 2*2*15

5.Safety Device: 2*SAJ50-1.2

6.Cage: Twin

7.Counterweight: Yes

8.Certification: CE,ISO

9.Place of Origin: China(Mainland)

10.Model Number: Type:SCD270/270

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

1. Quality raw material, strict production management and career responsibility to make the hoist with the highest safety control, and the advanced design make it with good vision to enhance the safety.

2. Simple structure and low cost

3. Convenient in installation, disassembly and maintenance.

4. Energy-saving, starting current is lower than the rated current.

5. Adjustable speed, the maximum speed could reach 96m/min.

6. Frequency conversion control system, stable starting and breaking and low mechanical wear

Construction Hoist Specifiction

Single cage High speed

Model | Speed(m/min) | Deadweight(kg) | Motor(KW) | Counterweight | Specification(L×W×H)(m) |

SC100G | 96 | 1000 | 3×22 | No | 2.5×1.3×2.5 |

SC120G | 96 | 1200 | 3×22 | NO | 3.0×1.3×2.5 |

SCD200G | 96 | 2000 | 3×15 | Have | 3.2×1.5×2.5 |

SC200G | 96 | 2250 | 3×22 | No | 3.2×1.5×2.5 |

SC270GS | 96 | 2700 | 3×22 | No | 3.8×1.5×2.5 |

SCD270G | 96 | 2700 | 3×18.5 | Have | 3.8×1.5×2.5 |

SCD300G | 96 | 3000 | 3×22 | Have | 4.0×1.5×2.5 |

SCD320GS | 96 | 3200 | 3×22 | Have | 4.2×1.5×2.5 |

Single cage Medium speed

SC100GZ | 63 | 1000 | 3×15 | No | 2.5×1.3×2.5 |

SC120GZ | 63 | 1200 | 3×15 | No | 3.0×1.3×2.5 |

SCD200GZ | 63 | 2000 | 2×15 | Have | 3.0×1.3×2.5 |

SC200GZ | 63 | 2000 | 3×18.5 | No | 3.0×1.3×2.5 |

SC225GZ | 63 | 2250 | 2×18.5 | No | 3.2×1.5×2.5 |

SC225GZ | 63 | 2250 | 3×18.5 | Have | 3.6×1.5×2.5 |

SCD250GZ | 63 | 2500 | 2×18.5 | Have | 3.6×1.5×2.5 |

SC250GZ | 63 | 2500 | 3×18.5 | Have | 3.8×1.5×2.5 |

SCD270GZ | 63 | 2700 | 2×18.5 | Have | 3.8×1.5×2.5 |

SC270GZ | 63 | 2700 | 3×22 | NO | 4.0×1.5×2.5 |

SCD300GZ | 63 | 3000 | 3×15 | Have | 4.0×1.5×2.5 |

SCD320GZ | 63 | 3200 | 3×15 | Have | 4.2×1.5×2.5 |

Single cage standard speed

SC100TD | 36 | 1000 | 2×11 | NO | 2.5×1.3×2.5 |

SC120TD | 36 | 1200 | 2×11 | NO | 3.0×1.3×2.5 |

SC200TD | 36 | 2000 | 3×11 | NO | 3.0×1.3×2.5 |

SCD200TD | 36 | 2000 | 2×11 | Have | 3.2×1.5×2.5 |

SC270TD | 36 | 2700 | 3×15 | NO | 3.6×1.5×2.5 |

SCD270TD | 36 | 2700 | 2×11 | Have | 3.8×1.5×2.5 |

SC320TD | 36 | 3200 | 3×18.5 | NO | 4.0×1.5×2.5 |

SCD320TD | 36 | 3200 | 2×11 | Have | 4.2×1.5×2.5 |

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: What are the requirements for the construction elevator

- So for safety device factory test is very strict, before delivery by the statutory inspection unit for torque measurement, critical speed measurement, measuring the amount of spring compression, each with the test report, after assembly to the construction lifter for drop test under rated load, and the site to use the elevator must be every three months to conduct a drop test. For safety device to the factory for two years for safety device (delivery date), must also be sent to the statutory inspection unit to carry on the test, after testing once a year.

- Q: What about the energy efficiency of the escalator

- The frequency conversion construction elevator is now basically the mainstream product, the effect is good, the failure rate is low and so on the advantage.

- Q: This question asks for an explanation of the working mechanism of a building hoist, which is a device used in construction to lift materials and workers.

- <p>A building hoist, also known as a construction hoist or personnel/material hoist, is a temporary lifting device used in construction projects to transport workers and materials vertically within a building. It typically consists of a tower, a cage, a drive mechanism, and a control system. The tower is attached to the building's structure, and the cage is where people or materials are loaded. The drive mechanism, often powered by an electric motor, raises and lowers the cage along the tower. The control system manages the movement, ensuring safety features like speed control and emergency stops are in place. The hoist operates within a guide rail system, which keeps it aligned as it moves up and down the building's height.</p>

- Q: This question asks whether a hydraulic building hoist can be used in both indoor and outdoor environments and seeks reasons for its versatility.

- <p>A hydraulic building hoist can be used both indoors and outdoors. These hoists are designed to be versatile and durable, capable of withstanding various weather conditions when used outdoors. They are also compact and can be easily maneuvered in indoor spaces. The primary reason for their versatility is the robust construction and the ability to handle different loads with precision. Additionally, hydraulic systems are less affected by electrical interference, making them suitable for environments with fluctuating power supplies. However, it's important to ensure that the hoist is properly maintained and protected from extreme weather conditions to prolong its lifespan and ensure safety.</p>

- Q: This question asks for the process of changing the speed at which a building hoist cylinder operates.

- <p>Adjusting the speed of a building hoist cylinder involves several steps. First, ensure the hoist is turned off and disconnected from power. Check the manual for the specific model to understand the speed control mechanism, which could be a variable frequency drive (VFD), a governor, or a throttle control. If it's a VFD, adjust the frequency setting to increase or decrease speed. For a governor, you might need to change the spring tension or adjust the control valve. With a throttle control, simply turn the throttle to the desired speed setting. Always test the hoist at low loads first to ensure the adjustments are safe and effective before using it for heavy loads.</p>

- Q: This question asks if a building hoist is capable of lifting objects that vary in size and weight.

- <p>Yes, a building hoist can be used to lift objects of different sizes and weights, but it is crucial to ensure that the hoist's capacity is suitable for the load. Building hoists are designed to handle various materials and equipment during construction, and their lifting capacity can range from a few hundred pounds to several tons. It is essential to check the hoist's specifications and adhere to the maximum load limit to ensure safety and prevent damage to the hoist or the objects being lifted. Always follow the manufacturer's guidelines and safety standards when operating a building hoist.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: This question asks for the procedure or steps to operate a building hoist, which is a machine used to lift materials in construction.

- <p>To use a building hoist, first ensure it's properly installed and inspected. Familiarize yourself with its controls and safety features. Load materials evenly onto the platform, ensuring not to exceed weight limits. Activate the hoist by pressing the 'up' button to lift the materials. Maintain a safe distance while the hoist is in motion. Once at the desired floor, press the 'stop' button, then unload the materials. Always follow the manufacturer's guidelines and safety protocols to prevent accidents.</p>

- Q: The tower crane is on a surface with the construction elevator, and only 2 or 3 meters away. Is that allowed

- There are no rules for the distance between tower crane and construction elevator, but note the following points: (1) the foundation of the tower crane and the construction elevator cannot affect each other; (2) the construction elevator shall not be higher than the tower crane. (3) the location of the elevator shall not be blocked by the position of the construction elevator; (4) the use of the same circuit and the same distribution box with the construction elevator shall not be used by the tower crane. The distance between the tower crane and the construction elevator can be anywhere, as long as the above aspects are met.

- Q: What are the fundamental parts that make up a building hoist?

- <p>The basic components of a building hoist include the hoist machine, mast or tower, guide rails, lifting cage, counterweight system, safety devices, electrical control system, and communication system. The hoist machine powers the lifting and lowering of the cage, while the mast provides structural support. Guide rails ensure the cage moves vertically, and the counterweight balances the cage's weight. Safety devices protect against accidents, and the electrical control system manages operations. The communication system allows for coordination between the hoist operator and other construction personnel.</p>

Send your message to us

Construction Hoist Building Lifter SCD270/270

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords