Concrete pump 40 concrete output

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete pump 40 concrete output

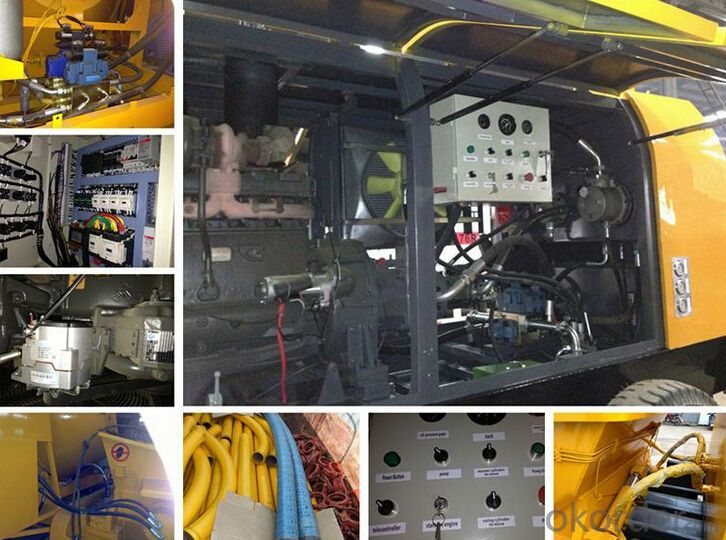

1.Power system

Hydraulic oil pump: Germany Rexroth or Japan Kawasaki are adjusted.

Diesel power: Germany Deutz, Weichai, Schneider, Japan Siemens, Mitsubishi are adjusted.

The main power could be adjusted by the user

2.Electronic control system

Japan Mitsubishi Programmable Logic Controller (PLC) electronic control system.

Main electric elements are imported original Schneider, Siemens, OMRON, LG etc.

The control mode: manual operation and wireless remote control

Humanity and intelligent electronic control system optimizes the person-machine interface.8-digital pumping time accumulation timer provides exact data for the user, Automatic anti-pump function and optimized program design. Automatic trouble monitoring function.

3.Hydraulic system

The unique open hydraulic system and hydraulic cushion technology contribute to the smaller exchange impact and less heat of the system.

Meanwhile, with the famous brand of main pump and hydraulic valve, the safety and reliability of the concrete pump are guaranteed.

The hydraulic pipeline selects the high performance seamless steel pipes and all pipe joints and high-pressure hoses are of the famous brands.

A number of high pressure accumulators and their excellent cushion performance reduce the requirement of S pipe vale for the concrete.

The concrete is delivered freely.

4.Pumping system

Pumping displacement variable adjustment: Change the pumping displacement according to the construction to meet the requirement of the condition.

Reducing design of the hopper could release the reducing pressure of the concrete into the delivery pipe maximally, and prolong the service life of the S pipe outlet.

5.Lubrication System

The patented central automatic lubrication system comes with a piston grease-pump, features high pressure and reliability, which can realize automatic lubrication of piston. The filters at the outlet and the inlet of oil ports as double protections guarantee the system reliability.

6.Cooling System

Compulsory air-cooled heat exchanger keeps the temperature of the hydraulic oil below 60 degree, that ensures the whole hydraulic system works at normal status.

Main parameters:

Item | HBTS40—12—55 |

Max Theoretical Concrete Output (Low/High pressure) (m³/h) | 40 |

Max Concrete outlet Pressure (Low/High pressure) (Mpa) | 12 |

Concrete slump (mm) | 120—230 |

Aggregate Size (mm) | gravel≤40 |

Powder (KW) | Electric motor 55 |

Speed (r/min) | 1480 |

Conveying Cylinder Diameter (mm) | Ø 100/1600 |

Concrete Cylinder Diameter (mm) | Ø 180/1600 |

High-Low Pressure Switch | Yes |

Fuel Tank Capacity (L) | 400 |

Hopper Capacity (m³) | 0.52 |

Filling Height (mm) | 1400 |

Maximum Theoretical Conveying Distance (vertical Height/Horizontal Distance) (m) | 150/850 |

Pipe Cleaning Mode | Washing |

Overall Dimension (mm) | 5020*2010*2200 |

Total Weight (kg) | 4308

|

- Q: When the concrete pump in the transport of concrete before the pipeline should be what lubrication

- And then share a coup, tanker to a lot of time, the site to prepare some sugar, if the pouring time is too long, the general 9 square tank you put 1 kg of sugar can be used as a retarder

- Q: How to determine the concrete pump truck blocking the site

- Pumping action and hydraulic system are normal, no abnormal sound and vibration, the hopper has a larger aggregate or agglomeration, at the feed port stuck or arch and blocked.

- Q: What is the difference between fine stone concrete pump and tow pump?

- The fine stone concrete pump is a fine stone concrete transportation equipment specially developed for the construction of warm ground and other construction features. It has successfully used the advanced development method to deal with the problems in the construction of warm ground and other concrete construction projects.

- Q: What is the history of the concrete pump

- In the late 1960s, Putzmeister launched a 16-meter boom pump truck. In 1998, Sany Heavy Industry successfully developed China's first 37-meter boom pump with independent intellectual property rights, breaking the foreign brands to the Chinese market

- Q: What is the diameter of the concrete pump tubing?

- Pump tube is generally divided into 125 and 150 two, diameter is 125mm and 150mm.

- Q: What are the brands of concrete pump trucks?

- The domestic brand-name Sany, the Union, foreign brand-name elephant, Shi Weiyin, etc., but the brand price is also expensive, choose a small brand to be able to buy brand-name or buy homemade it, I think our country's construction machinery is still good

- Q: Whether the concrete pump truck is paying the vehicle additional tax

- According to the General Administration of Taxation explained: only with a fixed device, non-transport vehicles can be exempted

- Q: Why is my concrete pump often appear plugging phenomenon?

- Pumping, the speed of the choice is critical, the operator can not blindly map fast, sometimes haste makes waste.

- Q: How to deal with pumping concrete pump pipe pipe burst after the burst, the pump can not stop the situation?

- There is no universal card, because there is no need.If you do not have a spare tube, you can also find a welding machine, the place where the patch will be patched on temporary work, if nothing, that your work is too poor to prepare, can only clean up the pipeline,

- Q: What is the difference between the concrete pump and the concrete pump?

- Concrete pump, also known as concrete pump, composed of pump and pipe. Is a use of pressure, the concrete along the pipeline continuous transport of machinery, mainly used in housing construction, bridges and tunnel construction. At present, it is mainly divided into gate valve concrete pump and S valve concrete pump. Another kind of pump body is installed in the car chassis, and then equipped with retractable or inflected cloth rod, and the composition of the pump.

Send your message to us

Concrete pump 40 concrete output

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords