Composite Durable and Corrosion-Resistant Gre Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Advantages:

1. Durable in use and corrosion-resistant:the surface of internal and external can resist many kinds corrosion of chemicals, crude oil. injected water and bacteria.

2. Light weight: 24% weight of ductile iron, it is convenient for installation in the absence of heavy machinery and large tools.

3. Low cost: Internal surface can reduce friction and the cost of transporting by pump.

4. Efficient and eneray saving: GRE pipe compared with steel tube can reduce the consumption of heat.

5. The solution of pipe system: The whole FRP pipe have different size, pipe joints, pressure rating for choice.

6. The long life cycle and low cost: There is almost no maintenance costs after installation and use, and it has higher lifetime cost compared with steel tube.

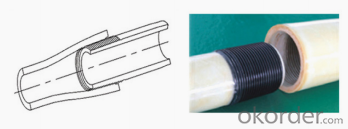

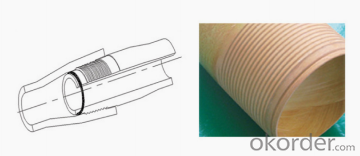

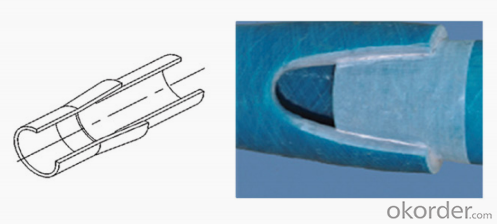

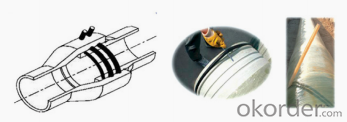

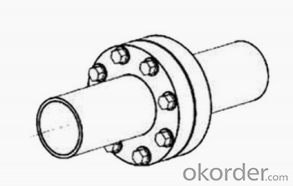

Joint type:

1. API thread application: High pressure oil & gas & water pipeline

2.T thread joint application: High pressure oil & gas & water pipeline

3.Bonding joint application: Underground low pressure pipeline

4.Locking key joint application: Underground low pressure pipeline

5.Flange joint application: Pipe and pipe or pipe joint other equipment

6.Lamination joint application: Low pressure pipeline connection

Produts Application:

1.Oil & gas-onshore:

Crude oil gathering line

Injected water

Macromolecule

Process pipeline in station

LNG pipeline

1. Vessel and offshore platform

Ballast water

Cooling water

DrainageFresh water pipe

Drinking water

Fire fighting water pipe

Sea water transport

Sewage transport

2. Bittern special purpose

Transport bittern

Transport sewage

3. Underground pipe and casing pipe

CBM casing pipe

Shale gas casing pipe

Underground oil pipe

Oil casing pipe

Product Performance:

The corrosion picture comparison between ordinary steel pipe and FRP pipe:

Performance comparison between ordinary steel pipe and FRP pipe:

Comparison Item | GRE pipe | Ordinary Steel Pipe |

Corrosion Resistance | Good corrosion resistance | Bad corrosion resistance |

Service Life | 20-30 years(the designed service life is more than 50 years ) | 5-10 years (nocathodic protection and preservative) |

Frictional Resistance | Smooth inner wall can reduce the accumulation of paraffin and scale;Low surface friction increase the flow of fluid velocity | The rough inner surface is easy to form scale and paraffin deposition;High surface friction leads to loss of workpressure |

Insulation Performance | There is no minimum and additional insulation material" requirement under high temperature and harsh environment | A lot of heat loss under the condition of high temperature |

Engineering Installation | Light weight, low cost of installation and transport | High weight, high cost of installation and transport |

Maintenance Fecs | It almost need no repair | Need anti-corrosive paint, cathodic protection and corrosion monitoring |

Environmental Performance | Low energy consumption in the process of productionand use | High energy consumption in the process of production and use |

Production Information:

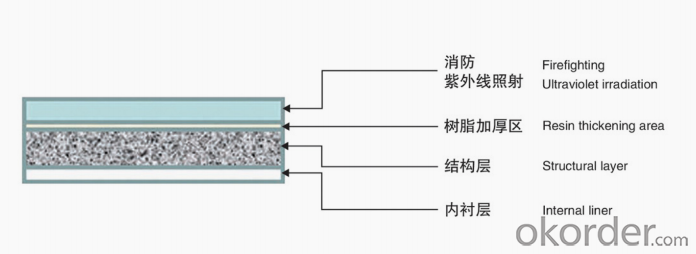

GRE wall structure:

∙ Pipe internal liner is used for anti-corrosion

∙ Pipe structural layer is used for pipe strength

∙ Anti-uv protection can used in pipe external to resist uv & the weathering exposure and environmental protection

∙ If high flow conducting electrostatic discharge need, GRE pipe can be used to conduct harmful static electricity discharged in the danger zone

In the fire, protective layer meet the fire resistance performance of protection box, required by firefighting, and produce less harmful gas.

Jet fire and fire-resistant experiment:

Level 3 fire-resistant experiment:

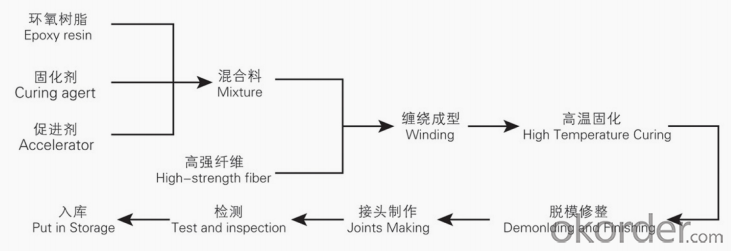

Production Method:

∙ Filament winding is used for both pipe and fitting production.

∙ The fiber glass will be winded on the mandrel after soaked into the resin. The mandrel will be rotated according to programmed mode.

∙ Multiply mandrels can be winded at the same time with one winding machine which has improved the work efficiency and guaranteed the quality.

∙ The winding of pipe fittings I flange, elbow, tee, coupling ) are made of two axis winding machines.

Production Process:

Quality Control:

Universal tester Differential scanning calorimeter (DSC)

Drying oven Fatigue tested machine

Before delivery, all pipes conduct 100% hydrostatic pressure monitoring in accordance with API standard.

Standard & Specification:

∙ API 15HR Specification for High Pressure Fiberglass Line Pipe

∙ API 15LR Specufcation for Low Pressure Fiberglass Line Pipe and fittings

∙ ISO 14692 Petroleum and natural gas industries - Glass-reinforced plastics (GRP) piping

∙ AWWA C950 Standard for fiberglass pressure pipe

∙ AWWA M45 Fiberglass pipe design

∙ IMO Res.A753(18) Plastic pipes on the ship

∙ ASTM F1173 Standard Specification for Thermosetting Resin Fiberglass Pipe Systems to Be Used for Marine Applications

∙ ASTM---D2996 Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

∙ API 5B Casing, tubing. line pipe thread specification

- Q: Why FRP pipes for outdoor waste gas treatment equipment are selected?

- Therefore, the outdoor waste gas treatment equipment is usually made of glass fiber reinforced plastic.

- Q: Is the installation of FRP pipes required qualification?

- Generally speaking, the glass steel pipe manufacturers will be installed for shipyard workers training, but if the shipyard did not ask, the training goal is to allow workers to master the skills to install, but they do not grant workers qualification certificate, but some shipyard will require workers engaged in installation with the installation qualification, so manufacturers will end in training workers to master confirmation the installation skills of workers, awarded the class approved qualification certificate. I don't know. Are you clear about that?.

- Q: Do I need CCC certification for ventilated GRP?

- Usually fiberglass, air conditioning, ventilation pipes will have insulation requirements, the general need not heat preservation.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- It is generally assumed that it is made of glass fiber reinforced plastic. The main pipe is made of glass fiber reinforced plastic. The medium is corrosive. Other materials must not be suitable

- Q: What are the materials used in smoke exhaust pipes?

- The exhaust pipe in the environmental protection system is divided into: suction duct, mine gas drainage pipe, coating cloth cylinder etc. in mine industry and construction industry in the central air conditioning system of factory and office building, with dust, smoke, oil, exhaust pipe, industrial environment with comfortable air supply pipe or post industrial pollution control. The exhaust pipe in accordance with the use of this distinction is several, the exhaust pipe is generally not used in building drainage pipeline in the smoke tube, because the rain is very prone to corrosion of steel, so in general use PC tube drain pipe.

- Q: Which is better, PVC pipe and GRP pipe?!

- Of course, FRP pipe, high strength, aging resistance, PVC too crisp

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has some disadvantages. (1) the bending of the guiding hole and the protruding rock, pebble and gravel in the hole will cause friction and scratch to the relatively soft 3PE corrosion resistant layer. (2) 3PE coating using polyethylene heat shrinkable sleeve joint, the convex part of the concave or lap joint, which makes it easy to travel being scratched or pulled off lead. (2) 3PE corrosion protection layer has a strong electrical shielding, so that the cathodic protection current is difficult to reach the defects of corrosion protection layer, thus causing perforation corrosion.So, from the last century at the beginning of 90s, the United States developed Powercrete (s) Powder Concrete Anticorrosion structure, namely in the bottom of fusion bonded epoxy powder, sprayed with epoxy resin as main film-forming material, and adding a two-component epoxy coating for concrete, polymer concrete curing agent and other inorganic fillers. The coating is tough and wearable and can be used directly in FBE coated pipes to protect the pipe from damage during handling, directional drilling, crossing, etc..

- Q: Who knows, how is the glass reinforced septic tank connected with the municipal pipe?

- If a glass fiber reinforced plastic outlet pipe is reserved, a new sewage inspection well is installed at the pipe end, and then a sewage pipe is installed to connect the reserved manhole of the municipal sewage pipe.

- Q: What is the compressive strength of all kinds of FRP materials?

- Heat resistance, frost resistance: at -30 DEG C, still has good toughness and high strength, can be used for a long time in the range of -50 DEG C 80 DEG C, the temperature of resin with special formula can be more than 110 DEG C. 4) of light weight, high strength, convenient transportation and installation by fiberglassreinforcedplastic pipe winding fiber production, the proportion of 1.65 - 2, 1 / 4 only of steel, but the glass steel hoop tensile strength is 180 300MPa, the axial tensile strength of 60 150MPa, similar to alloy steel. Therefore, its specific strength (strength / density) is 2-3 times that of alloy steel, so that it can be designed according to different requirements of users to meet all kinds of internal and external pressure requirements of the pipeline. For the same diameter of single FRP tube, only carbon steel (steel plate) 1 / 2.5, 1 / 3.5 of the cast iron pipe, about 1 / 8 of prestressed reinforced concrete pipe, so the transportation is very convenient for installation. The GRP pipe is 12 meters per length, and can be reduced by 2/3 from the concrete pipe. The socket connection mode of the utility model has the advantages of quick and simple installation, low hoisting cost and improved installation speed. 5) small friction resistance, high transport capacity: glass tube wall is very smooth, roughness and friction resistance is very small. The roughness coefficient is 0.0084, while the n value of concrete pipe is 0.014, and the cast iron pipe is 0.013. Therefore, glass fiber reinforced plastic pipe can significantly reduce the loss of fluid pressure along the course and improve the conveying capacity.

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- Hebei, Qingdao and Beijing have additional production bases and service liaison points. Willing to work with new and old customers to create a beautiful today, Chinese and foreign. The company with integrity development guide thought, company value go production, learning and research Jimo road. The wide customers and cooperation of different geographical identity peer praise richly endowed by nature is a unique, Wuhua Tianbao, day people for the auspicious clouds. The sludge produced by the glass fiber reinforced concrete grille has good sedimentation, which is beneficial to the removal of the suspended substance in the back section. The glass fiber reinforced concrete grille has strong adaptability, can adapt to different water quality range, and has strong endurance to the shock load of water quality and water quantity sudden change. FRP grating treatment efficiency is higher than activated sludge process. The galvanized grating plate has the advantages of advanced structural design, optimum matching of gas and water, and sufficient heat exchange, with the same level in foreign countries and superior output. Galvanized grille plate steel bracket adopts zinc plating treatment, double paint anti-corrosion or electrostatic powder spraying, corrosion resistance is strong, service life over similar products double. The two-way grille ensures the natural delamination of the medium and the impurity, and at the same time, the discharge method is arranged at the bottom of the tank, so that the cleaning is particularly convenient

Send your message to us

Composite Durable and Corrosion-Resistant Gre Pipes

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.