Composite FRP Process Pipe/Light Weight and High Strength FRP Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Process Pipe Description

1) Antifouling, anti-moth, non-rust, keeping water from pollution; It also apply to carry the polluted water, slurry and seawater;

2) The ability of water resistance and corrosion resistance can prolong product service life;

3) The connection of insert makes airproof excellent; project cost can be reduced without building concrete protect layer;

4) Few joint and various of joint methods not only reduce water resistance but also project cost;

5) Good insulation, heat resistance, combustration resistance; No distortion in high temperature of 80-100 degree;

6) With light weight, high strength, the hoisting cost can be decreased, also expedite installation proceeding;

7) Low maintenance expense: no need for antirust, anti-pollution, insulation, heat preservation and the relative examination and repair; cathode protection free also can save the project maintenance cost.

2. Main Features of FRP Process Pipe

1) Corrosion resistance

2) Lightweighta high strength

3) Easy installation

4) Low temperature-perform

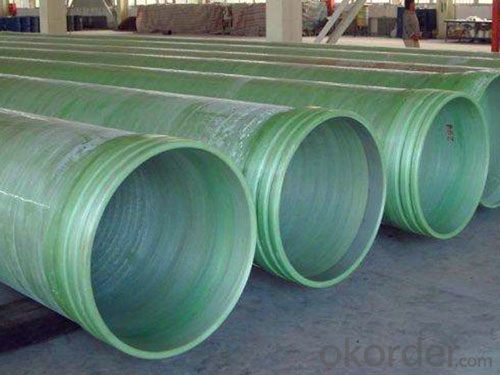

3. FRP Process Pipe Images

4. FRP Process Pipe Specification

1)Small specific gravity, light weight: FRP pipe’s specific gravity is 1.65-2.0 and one 1/4 compared with steel; hoop flexible tensile strength for FRP pipe is 150-420 MPa and axis tensile strength is 60-150MPa, similar to alloy steel. FRP pipe’s strength/specific gravity is 2 or 3 times compared with alloy steel so it can be designed according to customers different requirements for various pips bearing inside and outside pressure. For the same diameter pipe, FRP pipe’s weight is 1/2.5 compared with carbon steel pipe, 1/3.5 compared with cast iron pip, 1/8 compared with reinforced concrete pipe, so it’s easy for construction and transporting.

2) Fewer joints and efficient installment: Usual pipe’s length is 4-12 meters(other special length is also available according to customer demands). Single pipe is long with few joints to accelerate installment speed and reduce the fault possibility then improve efficiency of quality of construction of whole pipe.

5. FAQ of FRP Process Pipe

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: FRP pipe price

- The price range of raw material resin is about 10000/ tons to 60000/ tons.

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- Glass tube wall thickness is generally determined by the manufacturer design, with stereotypes products and sequences, you can choose according to the pressure level.

- Q: FRP acceptance standard

- Check radial deflection values. In accordance with the requirements of the specification, the FRP pipe installation shall be completed within 24h, the initial radial deflection of the pipe shall be tested, and the pipe shall not be raised, flattened or otherwise mutated.

- Q: FRP duct material plan is how to mention?

- Process design according to user's requirements and choose what material to use. Then according to the drawings and process, calculate the amount of various materials. According to the delivery date and production schedule, you can write the material schedule.

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- The general ratio is 1 to 0.001

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- Do not know the road of glass steel flange have, if any to buy different materials of cast iron flanges or PVCU flange on the same material, the three way behind the pipeline branch, so that the material market has purchased (ABS buy buy in the small town is not easy), the construction is convenient. If it is a glass steel pipe, pipe end cannot change, can only be used to bond the glass steel material, the pipe bonded on the flange is an arc for a plane is bonded with a cast iron pipe flange suggestions. Because the FRP material and most of the plastic are not bonded.

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- FRP cable pipe is a new type of composite material, it formed with resin as matrix and glass fiber reinforced composite materials, and unsaturated resin bonded molding and high quality cable protection is matched with the modern cable engineering construction with catheter products. Strong pressure resistance, light weight, smooth inner wall and small friction coefficient. It is easy to use the cable and does not damage the cable. Moving and transporting are easier and more convenient than metal pipe and concrete pipe. Construction and installation are simple and convenient and save labour.

- Q: Why more and more people choose FRP pipe?

- And the price ratio of FRP pipe is not much cheaper, and although the hardness of concrete pipe although FRP pipe to be hard, but the toughness and tensile strength is poor, the pressure is not good, and the cost is expensive, because more and more people use glass steel, and the price is expensive, with longer life.

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- Glass fiber reinforced plastic is another name for glass fiber reinforced plastics, commonly known as FRP (Fiber Reinforced Plastics), that is, fiber reinforced composite plastic. Depending on the fiber used, glass fiber reinforced plastics (GFRP), carbon fiber reinforced plastic (CFRP), boron fiber reinforced composite plastics and so on are classified. It is a kind of composite material made of glass fiber and its products (glass cloth, band, felt, yarn, etc.) as reinforcing material and synthetic resin as base material. Fiber reinforced composites are composed of reinforced fibers and matrix. Fiber (or whisker) diameter is very small, generally below 10 mu m, less defects and smaller, fracture strain of about 30/1000, is brittle material, easy to damage, fracture and corrosion. The matrix is much lower in strength and modulus than fiber, but it can withstand large strains, often with viscoelasticity and elasticity, and is a ductile material.

Send your message to us

Composite FRP Process Pipe/Light Weight and High Strength FRP Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords