Home Depot Flexible Duct - Combine PVC Aluminum Foil Flexible Ducts for HVAC System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 litre

- Supply Capability:

- 500000 litre/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Duct Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil duct:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

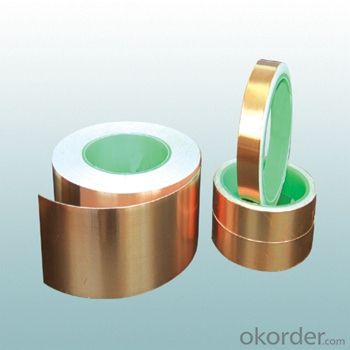

3.Aluminum Foil duct Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: Will metal hose be used on the wastewater treatment equipment?

- I think the most Easy to find expert design, rather than the general artisans knowChina's external wall insulation industry portal to provide users with a lot of information, you can refer to the next

- Q: For example, HDPE pipe with a flexible connection is a flexible interface, PVC-U of the glue plug-in method, is just helium pouring a lie on the pizza pull the interface, wire then, flange it more

- Project Name: Construction Lifting Machinery Safety Supervision and Management Provisions Expiry date: June

- Q: Drain flexible pipe to keep the base design above the elevation of the number of meters

- Fourth, the internal structure of the flexible pipe joints and KRJ internal structure is slightly different, flexible pipe joints without back Taiwan or small back out of the station, while the latter is the big back five, flexible pipe fittings standard clamp type flexible pipe fittings disassembly Of the time can be used grinding demolition, shoulder type flexible pipe joints can not Note: Some units on the market now mix these two products, the purpose is to sell low prices for low-priced products, so you can get more profit margins To ask for the data parameters of the drawings to determine whether the flexible pipe joints or flexible pipe joints

- Q: Do you have a natural gas hose in the flue?

- Fastening steel pipe scaffold generally by the steel pipe rods, fasteners, base, scaffolding, safety net and other components of steel pipe: generally there are two, an outer diameter of 48mm, wall thickness 3

- Q: Does the desulfurization and denitrification equipment use metal hoses?

- Fire pipe clamp connector leak technical details Detailed: trench-type fire pipe in the use of a long time after the sudden pressure relief occurs after the pipeline displacement caused by leakage of the clamp joints, light with a tight clamp clamp is not necessarily good Effect, because the rubber ring aging, lack of flexibility. The best way to do this is to remove the trench clamp from the inner wall of the trench with a "3mm" thick rubber (available with a thin car inner rubber) with a width of about 2 " ~ 3mm ", cut and then fasten the clamp bolts, water leakage problem is solved.

- Q: Safety evaluation: gas pipeline and discharge pipe should not be set between the valve, what is the specification of which provisions?

- In the past, the external wall insulation technology prevails, the external wall insulation is in the experimental stage, Basically no

- Q: How is the flexible casing of the fire pond connected to the tube?

- EPS expansion polystyrene board: is a volatile liquid blowing agent containing polystyrene (eps) beads, preheated by heating after the mold in the mold, with fine closed-cell structure characteristics

- Q: What is the difference between a rigid pipe and a flexible pipe, what kind of pipe is rigid, what is flexible

- Tower crane is used to lift objects up and down the lifting of the object is not clear the length of the arm of the tower crane!

- Q: Is the clamp type flexible connector connected to the pipe to the rubber pad?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q: Is the flexible sleeve of the broken wall used as a second retest?

- The national standard is 18kg. Color steel sandwich panel is a common product in the current building materials, do not chu chu dumpling seal festival over the extinguished Long can only be a good flame retardant and environmentally friendly and efficient. Caigang sandwich board has two layers of metal panels and the middle of the polymer core insulation from the suppression. With the installation is simple, light and efficient light and efficient features. And the filling system used to close the molecular structure of the closed, you can put an end to the condensation of water vapor.

Send your message to us

Home Depot Flexible Duct - Combine PVC Aluminum Foil Flexible Ducts for HVAC System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 litre

- Supply Capability:

- 500000 litre/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords