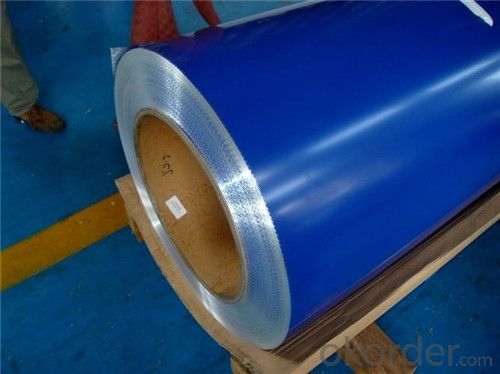

color coated galvanized Rolled steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Thickness : 0.14mm-1.2 mm

Width : 700mm-1250mm

Color : RAL code and as per customer

Zinc coating : 60-180g/m AZ 50-AZ275

Hardness : Normal soft/ Semi hard/ Full hard

Pre-Paint coating: 12-25um

Paint material: PE/PVDF

Color: Any color

Coil Inner Diameter: 508mm/610mm

Galvanized steel coil

Introduction:

The galvanized steel coil is made by cold rolled steel sheet, then trough chromated. unoiled, various spangles, hot dipped. The surface is coated by zinc or aluzinc. it is widely used as the raw materials of building. we have exported to midle east, africa, south america, ukraine for the good quality and best credit.

Specification:

Thickness : 0.14mm-0.8 mm

Width : 600mm-1250mm

Color : RAL code and as per customer

Zinc coating : 60-180g/m AZ 50-AZ275

Hardness : Normal soft/ Semi hard/ Full hard

Spangle: None spangle; Regular spangle; Big spangle

Surface treatment: Anti-finger/ None anti-finger

Coil Inner Diameter: 508mm/610mm

Add:

Topside: 5microns primer+ (10-20)microns polyester. Backside: 5-8microns primer epoxy.

The combining force between the galvanized or galvalume steel and the paint is very strong

The surface of Prepainted Steel Coil is normal or can be covered by film.

- Q: Can you use regular welding rods when welding stainless steel?Thank you.

- Yes you can use regular welding rods for stainless steel. But you will not have the properties of the stainless. The weld joint will have a different color than the stainless if you grind/grain/finish the weld. It could also rust. The joint could be weaker. It is best to use a rod that comes as close to the base metal stainless as possible. (30 years welding - certified)

- Q: How are steel coils used in the manufacturing of hydraulic cylinders?

- Steel coils are used in the manufacturing of hydraulic cylinders as the raw material for creating the cylinder body. The steel is typically rolled into a coil form and then cut into specific lengths and shapes to construct the cylinder barrel. This allows for precise and durable construction of hydraulic cylinders, ensuring they can withstand high pressure and heavy loads.

- Q: I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- Kershaw Steel

- Q: I need the measurements of the height and hypotenuse of the first drop in the Steel Dragon 2000. I couldn't find it anywhere. It would be great if you could also show me the website where you got your answer. Thanks! =]*The hypotenuse is the length of the drop.*

- Steel Dragon 2000 is a roller coaster at Nagashima Spa Land Amusement Park in Mie Prefecture, Japan. Built by Morgan Manufacturing, this gigacoaster opened, appropriately, in 2000 - The Year of the Dragon in the Far East. It debuted only months after Millennium Force and surpassed the Cedar Point coaster as the world's tallest complete-circuit coaster. It also set a record for longest track length - 8133 feet, 2 inches (2479 m), which it currently holds. Coaster Facts * Steel Dragon 2000 is the tallest coaster to utilize a traditional chain lift. Because of the length of the lift hill, two chains are used - one for the bottom half and one for the top half. A single chain would have been excessively long and heavy, at least twice the weight of one of the trains. As a result, two trains can safely occupy the lift simultaneously. * The building of Steel Dragon 2000 required far more steel than other coasters for earthquake protection. This put the cost of the coaster at over $50,000,000. * On August 23, 2003, Steel Dragon 2000 was involved in an accident during a run in which one of its trains lost a wheel. The coaster did not operate during the 2004 and 2005 park seasons. It reopened September 3, 2006.

- Q: How are steel coils used in the production of infrastructure materials?

- Steel coils are commonly used in the production of infrastructure materials due to their strength and versatility. These coils are often transformed into various forms such as beams, plates, or pipes, which are then used in the construction of bridges, buildings, roads, and other vital infrastructure. The malleability and durability of steel make it an ideal material for withstanding heavy loads and harsh environmental conditions, ensuring the longevity and stability of the infrastructure.

- Q: Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- Steel okorder /

- Q: What are the different methods of levelling steel coils?

- There are several methods of leveling steel coils, including roller leveling, stretcher leveling, and temper leveling.

- Q: Can steel coils be used in corrosive environments?

- Yes, steel coils can be used in corrosive environments, but their performance will depend on the type of steel and the severity of the corrosive environment. Stainless steel coils, for example, are highly resistant to corrosion and can be used in a wide range of corrosive environments, including those with high levels of moisture, chemicals, or salt. However, other types of steel coils may require additional protective measures, such as coatings or galvanization, to enhance their resistance to corrosion. It is important to consider the specific corrosive factors present in the environment and choose the appropriate type of steel and protective measures to ensure the longevity and durability of the steel coils.

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- Hey Ramzi, I met this chick and was wondering if you could tell me if she would make a good wife. Here's your answer: Big Blue, there are a hundred bits of information I would need, and even then there are mysterious factors that affect the outcome. So basically, I don't have the slightest idea. My answer to your question is exactly the same. Without showing exactly how the Simpson Tie is being used, there is obviously no way to know if it is suitable. Can it be tempered? Sure, but again, I give it a 99% likelihood it will not help in your application. Explain it in detail in 5 to 10 sentences. Give us diagrams and photos. If you can't or won't do that, here's Plan B. Head over to your nearest machine shop, and ask the machinist what he thinks. He will ask the probing questions to understand the needs of the part. It is likely a Simpson Tie won't do it but he is in a good position to suggest a workable approach, and then sell it to you. By the way, if this is a load-supporting member of a motorcycle or some other fast moving vehicle, be prepared to get kicked out of the machine shop. The risk of making an error is high and the outcome extremely dangerous. I would not risk a million dollar lawsuit in order to sell you a $10 part.

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems as they are rolled into sheets and then formed into various components such as shelves, frames, and brackets. These components are then assembled to create sturdy and durable storage systems that can hold and organize various items efficiently.

Send your message to us

color coated galvanized Rolled steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords