Aluminium Ceiling Singapore - Color Coated Aluminum Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Aluminum Coils For Building Materials

Production description

1. Alloy:1000,8000series

2. Temper:H24

3. Thickness:0.21-2.0mm

4. Width:600-1800

5. Standard: chemical composite: GB/T3198-2008,JIS,EN,AW,ASTM

mechanical property:GB/T3800-2006,JIS,EN,AW,ASTM

6. Certificate:ISO9001,SGS,ROHS,MTC,Certificate of origin(form a,form e,co)

7. Payment terms:t/t,irrevocable L/C at sight

8. Trade terms:FOB,CIF,CFR

Application

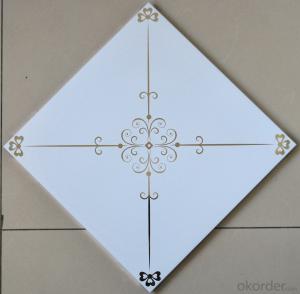

Interior applications:wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

Exterior applications: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

Advertisement and market applications: display platforms, signboards, fascia, shop fronts...

FAQ

--Q: How can I request a product sample?

A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

--Q: How can I request a product catalog?

A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

--Q: Wha's your payment terms?

A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

--Q: What's your trade terms?

A: FOB, CNF(CFR), CIF, EXW.

--Q: How long is the quality guarantee?

A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Can the aluminum plate be made of walls? How to build is better, how to install the ground

- Use of aluminum-plastic plate aluminum plate is usually used as a kitchen, bathroom ceiling. Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

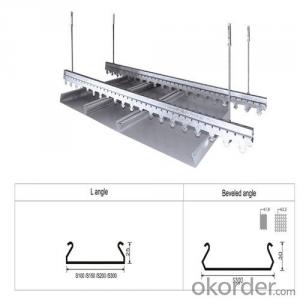

- Q: Aluminum cords hanging ceiling, you can turn it?

- es, the board Needless to say, processed into a circular arc Under the words, the corners are generally L-type, you can cut the corner of the place with scissors cut, bent into the garden, but this may cause a saw porcelain The shape of the need for plastic, if it is white or solid, you can draw two arcs arc, arc angle is equal to you need to do circular curvature of the anastomosis, arc size is equal to the width of the corner, you can try

- Q: Will the kitchen decoration, ceiling ceiling (aluminum plate) can install chandeliers. Master said that the general are decorated board LED lights. I do not look good. Seek answers.

- Kitchen soot too much, chandelier bad cleaning!

- Q: Aluminum plate and rock wool color plate which attracts the effect is good

- Because the rock wool color steel rock wool can play a sound-absorbing effect.

- Q: What are the benefits of aluminum ceilings?

- Advantages of aluminum ceiling: Compared with the traditional materials, metal ceiling with elegant color and diverse, three-dimensional sense of strong, decorative effect, and other decorative materials, such as tiles, marble, etc. can form a very coordinated overall decorative effect. Metal ceiling fire, waterproof performance, light material, high strength, easy aging, easy installation, with good sound absorption, sound insulation performance. There are easy to clean fumes, the use of good life long, not easy to deformation and other advantages.

- Q: Aluminum buckle ceiling ceiling how to do

- The card into the place to get closer, or the edge of the aluminum plate bent a little bit after the card into the just fine, you try

- Q: Integrated ceiling aluminum slab board know how much knowledge?

- The normal service life of the sprayed aluminum slab plate should be: 5-10 years; the normal service life of the roller plate should be: 7-15 years; the normal service life of the coated aluminum slab plate should be 10-30 years.

- Q: The kitchen lights in my house are broken! Ceiling lights are with the buckle board together, do not know where to start out, I would like to ask you how to get big? Need tool not? Thank you! anxious

- If it is the side of the aluminum plate, it is very simple, with a pass through the sewer of the child (chuāi zi) suction ceiling lamp near the center of the buckle, pull down, you can put that buckle off, If the plate there is a side of the keel caught in the folder sandwiched, to reach out and press the side there, in short, to close the buckle that off. The next step, reach out, the ceiling of the gongs are clamped by the keel of the two sides press down, you can put the ceiling of the buckle plate unloaded, for a good light after the buckle up as the original ok.

- Q: How to look good or bad

- Look at the keel: keel is good or bad is a lot of consumers ignore the problem, the keel material is generally divided into aluminum, iron and no fingerprint steel. Aluminum keel will not rust, but because the cost is relatively high sales so very little. Iron keel is easy to rust, although the keel section hidden in the back of the ceiling generally do not see, but the rust scattered on the ceiling on the ceiling is not good, over time will affect the stability of the ceiling. No fingerprint steel keel relative to the iron keel it is not so easy to rust, is currently the most commonly used home improvement tooling sales. I sincerely hope that consumers can buy their own ideal integrated ceiling products.

- Q: How much does it cost to produce an aluminum plate?

- Depends on what kind of processing you are the aluminum plate, the machine plus mold about 45000 or so, do not just look at the price, depends on Yingdefeng brand and quality

Send your message to us

Aluminium Ceiling Singapore - Color Coated Aluminum Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords