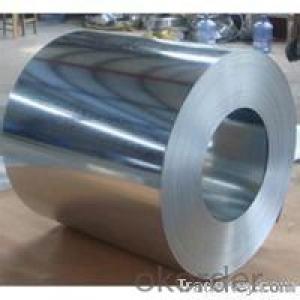

cold rolled steel - SPCE in Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

COLD ROLLED STEEL | |

THICKNESS | 0.3-0.5MM |

WIDTH | 600-1250MM |

SHEET LENGTH | 0-6000MM |

COIL ID | 508MM OR 610MM |

SURFACE TREATMENT | MATT FINISH/BRIGHT FINISH, OILED/DRY |

ANNEALING METHODS | BRIGHT ANNEAL/BLACK ANNEAL |

Advantage

1. High Quality SurfaceFinish

2. High Dimensional Precision

3. Excellent mechanicalproperty

Package & Delivery

Package details: Standardseaworthy packing for international delivery.

Delivery: According to theexact quantity of your order.

Quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many rocessing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing.

- Q: I have a belly button piercing and the metal is stainless steel.. I was wondering does it develop rust whenever you go shower and clean it? Can I still swim in the summer with it or do I have to take it out? What happens if I swim in the pool with it?

- No it won't rust. Just make sure to get the pool water out of the piercing when done at the pool. Just to avoid drying out the skin too much.

- Q: What are the different methods of coil blanking for irregular shapes?

- There are several methods of coil blanking for irregular shapes. One common method is laser blanking, which uses a high-powered laser to cut the shape directly from the coil. This method is highly precise and allows for complex shapes to be cut with minimal waste. Another method is water jet blanking, which uses a high-pressure stream of water mixed with abrasive particles to cut the shape from the coil. Water jet blanking is often used for thicker materials or when the material being cut is sensitive to heat. Additionally, there is also die blanking, which involves the use of a die to stamp the shape out of the coil. This method is commonly used for larger production runs and can be automated for increased efficiency. Lastly, there is also plasma blanking, which uses a plasma torch to cut the shape from the coil. Plasma blanking is often used for thicker materials or when high cutting speeds are required. Overall, the choice of method for coil blanking irregular shapes depends on factors such as material thickness, shape complexity, production volume, and desired precision. Each method has its advantages and limitations, and selecting the most suitable method is crucial for achieving optimal results.

- Q: How do steel coils contribute to the HVAC industry?

- Steel coils are essential components in HVAC systems as they play a crucial role in heat transfer. These coils are used in air conditioning units and refrigeration systems to facilitate the exchange of heat between the air and the refrigerant. The steel coils are designed to efficiently absorb heat from the indoor air and release it outside, enabling effective cooling. They help maintain comfortable indoor temperatures and enhance the overall energy efficiency of HVAC systems.

- Q: What are the dimensions of steel coils used in the agricultural machinery industry?

- The specific application and requirements play a significant role in determining the dimensions of steel coils utilized in the agricultural machinery industry. Generally, the dimensions of steel coils in this industry fall between 0.5 and 2.0 millimeters in thickness and 600 to 1500 millimeters in width. These dimensions are commonly utilized for agricultural machinery components like panels, frames, brackets, and reinforcements. It is worth mentioning that these dimensions can be tailored to meet the specific needs of the machinery or the manufacturer's specifications.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, which can make transportation and maneuverability difficult. Additionally, the edges of steel coils can be sharp and pose safety risks. Coils also need to be stored in a manner that prevents damage and corrosion. Lastly, processing steel coils requires specialized equipment and techniques to ensure accurate cutting, shaping, and forming, which can be costly and time-consuming.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of mechanical and/or thermal methods. The coils are first uncoiled and then passed through a slitting machine to cut them into narrower strips. The edges of these strips are then trimmed to remove any irregularities or excess material. This can be done through shearing, grinding, or milling processes. Once the edges are trimmed, the coils may undergo further conditioning processes like straightening, leveling, or rewinding to ensure they meet the required specifications.

- Q: How are steel coils tested for strength and durability?

- Steel coils are tested for strength and durability through various methods such as tensile testing, impact testing, and fatigue testing. Tensile testing involves subjecting the steel coil to tension until it breaks, measuring the maximum force it can withstand. Impact testing involves striking the coil with a heavy object to assess its ability to resist sudden shocks. Fatigue testing involves subjecting the coil to repeated load cycles to determine its resistance to long-term stress. These tests help ensure that steel coils meet the required strength and durability standards.

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Technically, this is known as ductility. a material which can be permanently bent and stretched is said to be ductile. Pure iron, when it lacks carbon and impurities like sulfur and phosphorus, is relatively soft, ductile, and weak. It's about as soft as brass. It can be stretched to about 50% of it's original length before it breaks. The amount a sample can be stretched without breaking is known as elongation. The key to steel is the addition of about 2 parts per thousand of carbon, or around 0.2%. This alters the crystal structure and makes steel much harder, stronger, and tougher, though it also becomes somewhat less ductile. Mild steel, with a low carbon content, has an elongation of around 30% Adding more carbon makes the steel yet stronger, but further reduces the elongation. Adding more than 2-3% carbon produces what is known as Cast Iron. Cast iron is brittle. It has virtually no ductility. It's pretty cheap to produce though.

- Q: What are the different testing methods used for steel coils?

- There are several testing methods used for steel coils, including visual inspection, dimensional measurement, hardness testing, tensile testing, chemical analysis, and non-destructive testing techniques such as ultrasonic testing and magnetic particle inspection. These methods help ensure the quality and integrity of steel coils, allowing for accurate assessment of their mechanical properties, composition, and structural soundness.

- Q: How are steel coils used in the production of consumer goods?

- Steel coils are used in the production of consumer goods as they are processed and shaped into various components, such as sheets, tubes, and wires. These components are then utilized in manufacturing a wide range of products, including automobiles, appliances, furniture, and construction materials. The high strength and durability of steel make it an ideal material for consumer goods, ensuring their longevity and performance.

Send your message to us

cold rolled steel - SPCE in Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords