Cold rolled steel prices from manufacturer china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 64450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

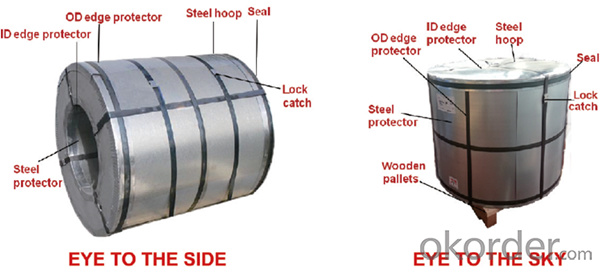

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: How are steel coils used in the manufacturing of storage shelves?

- Steel coils are used in the manufacturing of storage shelves by being cut and shaped into the desired size and design. The coils are typically processed through a roll forming machine which bends and molds the steel into the required shape for the shelves. This process allows for high efficiency and precision in creating uniform and durable storage shelves.

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- From what I read M390 is relatively wear resistant, with very high stain resistance and good toughness. It is quite hard to qualify steel as better than other steel because it depends on many factors. E.g. for a small folder designed for delicate cutting D2 at high hardness would perform better, but if the environment is corrosive, like saltwater then M390 would be better. I'm not so sure about using stainless steels in large chopping style knives, but I've seen M390 used for them as well. Obviously hardness had to be lowered, which reduces edge holding ability, especially at low angles. Overall, it's a good steel, but if it will outperform S30V or D2 or 154Cm depends on heat treatment and blade geometry, knife designed use, etc.

- Q: I want a good quality, big, strong, steel knife but I want it to be a good price, say around $30 or less, $60 at the most. please add links.

- DAGS for combat knife

- Q: What are the common applications of cold-rolled steel coils?

- Due to its exceptional qualities, cold-rolled steel coils find a wide range of common applications across various industries. The automotive industry extensively uses these coils to manufacture car parts like body panels, chassis components, and structural reinforcements, benefiting from the high strength and excellent formability of cold-rolled steel. Similarly, the construction industry relies on cold-rolled steel coils to fabricate structural elements for buildings and infrastructure. Beams, columns, and other load-bearing components are commonly made from cold-rolled steel due to its superior strength and durability. Appliances and consumer goods manufacturing also make use of cold-rolled steel coils. They are frequently employed to create the outer shells of refrigerators, washing machines, and ovens, thanks to the smooth and consistent surface finish that provides an aesthetically pleasing appearance. Furthermore, the electrical industry utilizes cold-rolled steel coils in the production of electrical enclosures, transformers, and various other components. The excellent electrical conductivity and magnetic properties of cold-rolled steel make it a preferred choice for such applications. In summary, cold-rolled steel coils have diverse applications in industries including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it the favored choice for manufacturers across various sectors.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized coatings, galvannealed coatings, and organic coatings.

- Q: I am making a sword of 1060 carbon steel and would like to know how to heat treat it once it's ready, could anyone help please?

- Heat treating easy, HA! It is the most critical part of bladesmithing. Done wrong and all those hours of work go up in smoke (or a snap of the steel). You'll need a bucket of oil, preferably one that is deep enough to go in point first. If not you'll have to go in edge first, not recommended on a double edged blade, ok for single edge. You'll need to build a charcoal fire long enough for the blade. You will need to blow air under the fire to get it hot enough, the challenge is getting the heat even. You get the fire going and established, put the blade in turning it back and forth (if you keep turning it in the same direction when it heats up you could work a twist in it). When it starts turning red pull it out and touch it with a magnet, if the magnet sticks put it back. Keep heating and repeating until the magnet no longer sticks. Heat a little more, then quench rapidly point first. Don't let the blade lean to one side as warpage will occur. When it cools enough to touch, check with a file. If the doesn't file cut then you've properly hardened the steel and it's ready for temper. Now comes the really hard part. Grind the scale off carefully,preferably with a side grinder with a flap wheel. I've had hard wheel break freshly hardened blades. After cleaning you'll need to put it in an oven (preferred) or use a torch and carefully heat the blade. Watch the temper colors (oven temp 500-550F) or with the torch as the steel turns colors blue to purple for a double edged weapon. Any warpage that occurs needs to be worked out at temping temp.

- Q: How are steel coils inspected for thickness variations?

- Steel coils are inspected for thickness variations using non-contact measurement techniques such as laser or ultrasonic sensors. These sensors are capable of accurately detecting and measuring the thickness of the steel coils at various points along their length. The collected data is then analyzed to identify any variations in thickness and ensure the quality and consistency of the steel coils.

- Q: How are steel coils annealed for improved properties?

- Steel coils are annealed for improved properties by heating them to a specific temperature and then slowly cooling them down. This process, known as annealing, helps to relieve internal stresses in the steel, increase its ductility, and improve its machinability.

- Q: I do a lot of scrapping and would like to be able to separate stainless steel from regular steel. The magnet test doesn't always work since stainless can be magnetic, but what are some ways that I can for sure tell the difference? Or even something like a sound that they make that may help me to tell the difference.

- Stainless steel uses chromium in its mixture to thwart the affects of corrosion. General steel, or carbon steel, is generally almost completely iron and is used for far greater applications than stainless steel. Stainless steel is used mostly in kitchen appliances, utensils, etc... The best thing I can come up with is to find a way to measure the chromium content of the steel you are looking at. If it's around 3% chromium, it's probably standard steel. If it's somewhere between 10-15% chromium it's probably stainless steel (or even 4% plus). I can't tell you a fast and quick way to test the steel because from my research, it appears there are as many grades and allows of steel as there are uses for steel! There is one test I've seen for home testing surgical steel which is a higher grade stainless steel, that is to put scotch tape on one section of material then soak it in water for a 24 hour period, then let it air dry for 24 hours. You remove the tape and lightly polish the exposed areas to see if there was any discoloration or pitting on the exposed area. This test is mainly for surgical steel jewelry, however stainless steel is supposed to resist rusting more than standard steel, hence it might work for other steel types as well. You may have to read some of the other links below to get some other ideas on how you can test steel to see if it is stainless.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being converted into cylindrical shapes through a process known as coil winding. These coils are then cut, shaped, and machined to create the desired dimensions and specifications for the transmission shafts. The high strength and durability properties of steel make it an ideal material for transmission shafts, ensuring efficient power transmission and overall performance of the machinery.

Send your message to us

Cold rolled steel prices from manufacturer china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 64450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords