cold rolled coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Cold Rolled Steel Coil/Sheet:

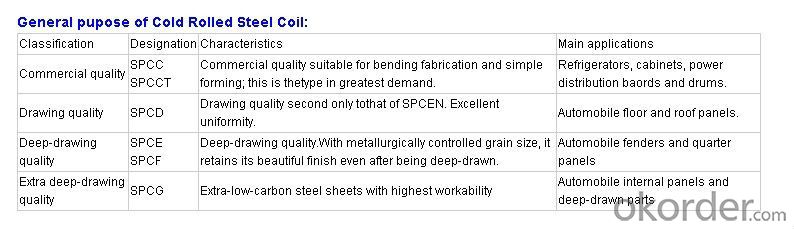

1)Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2)Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3)Thickness: 0.18mm - 3.0mm

4)Width: 600/1000/1250/1500 (mm) or per customer's request

5)Coil ID: 508mm/610mm or per customer's request

B:Package of Cold Rolled Steel Tape:

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or

wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

C: Applications for cold rolled Steel coil:

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel Coil: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

D:Process of Cold Rolled Steel Tape:

a: Pickling: To clean the dust and rust points on the surface.

b: Cold Rolling: Digital rolling control system produces minimum thickness tolerance, helps to prevent twist and improve straightness.

c: Slitting: Precise slitting machinery helps control the best width tolerance and avoid camber or cracker. Also we can make round or sharp edge with additional process and special machines.

d: Heat treatment: Advanced annealing, tempering and hardening techniques will help to produce proper mechanical property of the products to insure our client’s usage with minimum harm to natural environment.

E

F: Applications of Cold Rolled SteelCoil:

1) For the further producing of hot dip galvanized steel products

2) Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

Shipment time

within 30 workdays

Payment

T/T, L/C at sight

Market

North/South America, Europe, Asia, Africa, Mid East, ect.

Authentification

ISO9001:2000

- Q: How are steel coils used in the production of metal enclosures?

- Steel coils are used in the production of metal enclosures as they provide the raw material needed for forming and shaping the enclosure. The steel coils are processed and cut into sheets or strips, which are then bent, welded, or stamped to create the desired shape and structure of the enclosure. These steel sheets offer strength, durability, and a smooth surface finish to the final product, making them ideal for manufacturing metal enclosures used in various industries such as automotive, electronics, and construction.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: rust is not a issue. i was looking a D2 steel but heard story's of it chipping and breaking

- The very best is Damascus steel or the composite samari blade. Talk to the American Bladesmith Society if you are interested in forging your own or buying a forged blank and making the knife yourself. D2 and other similar tool steels are generally not a good choice because they can not obtain very high hardness but they should be tough (resistant to cracking) if they were heat treated properly. There are more ways to heat treat wrong than there are to heat treat right. Although you say rust is not an issue, 440 stainless steel is commonly used for commercial knives, it does not rust, holds a good edge, and is pretty tough.

- Q: Does anyone know how to make a steel helmet, or does anyone know where to direct me websites-wise? i've just started looking on the web for info, so when i get back here i might've already found some info, but more wouldn't hurt, especially if from people who are interested on the subject. i know nothing about metallurgy, nothing on the art of metal working etc... please help.

- Steel okorder

- Q: PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q: How do steel coils contribute to thermal insulation in buildings?

- Steel coils do not contribute to thermal insulation in buildings. In fact, steel is a good conductor of heat, so it can actually transfer heat rather than insulate against it.

- Q: What are the common packaging defects in steel coils?

- Some common packaging defects in steel coils include: 1. Edge damage: This occurs when the edges of the steel coil are not properly protected or wrapped, leading to dents, scratches, or even deformities along the edges. Edge damage can compromise the integrity of the coil and may result in reduced performance or structural issues. 2. Rust or corrosion: Steel coils are susceptible to rust or corrosion if they are not adequately protected during packaging. Exposure to moisture or harsh environmental conditions can lead to oxidation, resulting in the formation of rust spots or even widespread corrosion. This can weaken the steel and render it less suitable for its intended use. 3. Coil slippage: Improper packaging can cause the coils to shift or slip within the packaging material during handling or transportation. This can lead to misalignment, deformation, or interlocking of the coils, making them difficult to separate or use effectively. 4. Coil damage during handling: Rough handling, improper lifting techniques, or inadequate support can cause mechanical damage to the steel coils. This can result in dents, scratches, or even more severe structural damage, which may impact the functionality or performance of the steel coil. 5. Inadequate protection against impacts: Steel coils need to be adequately protected against impacts during transportation or storage. Insufficient padding or cushioning can lead to impacts or collisions, resulting in deformities, dents, or even fractures in the coil. 6. Improper coil strapping or banding: If the strapping or banding used to secure the steel coils is not properly applied or tightened, it can result in coil slippage or even complete unraveling of the packaging. This can lead to a tangled mess of steel coils, making them difficult to handle, transport, or use. 7. Insufficient labeling or identification: Proper labeling and identification are essential for efficient handling, storage, and tracking of steel coils. Inadequate or incorrect labeling can lead to confusion, delays, or even loss of the coils during transportation or storage. To avoid these common packaging defects, it is crucial to follow proper packaging guidelines, use appropriate packaging materials, provide adequate protection, and ensure proper labeling and identification of steel coils. Regular inspections and quality checks throughout the packaging process can help identify and rectify any defects before the coils are shipped or used.

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are used in the manufacturing of furniture to provide structural support and stability. They are commonly used in the construction of sofa frames and mattress bases to ensure durability and longevity. The coils are typically formed into springs, which are then incorporated into the furniture to enhance comfort and provide a responsive seating or sleeping surface.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: What are the common methods of welding steel coils?

- The common methods of welding steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

Send your message to us

cold rolled coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords