Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

Detailed Information of Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | ||

| A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu | |||

| A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 | ||

| Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

| Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

| Length: | 6000mm, 8000m, can cut to width and length | |||||||

| Packing Details; | according to customer‘s require or export’s standard | |||||||

| Delivery time; | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

| Port: | Tianjin China | |||||||

Related Products Overviews of Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Related Products Application of Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

Carbon Steel | l Mold bottom l Plastic mold l Construction machinery parts l Automobile parts l Security grills l Screens l Construction |

Bearing Steel | l Aerospace l Navigation l Nuclear energy l Chemical industry l Electronic information l Petrochemical l Instrument and meter l Transportation |

Cr-Mo Steel | l Mechanism & Fasteners gear l Stressed components for vehicles l Engines and machines l Parts of larger cross-section |

Gear Steel | l All kinds of gears l Statically and dynamically stressed component for vehicles l Engines and machine l Larger cross-section parts l Crankshafts |

Company Introduction of Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours

|

Advantages

| l Industry experience over 20 years. l Shipment of goods -More than 70 countries worldwide. l The most convenient transport and prompt delivery. l Competitive price with best service. l High technical production line with top quality products. l High reputation based on best quality products.

|

Packaging & Delivery of Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

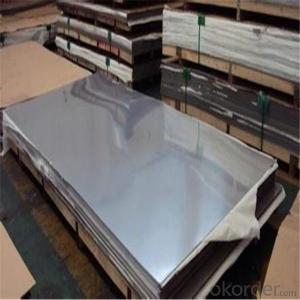

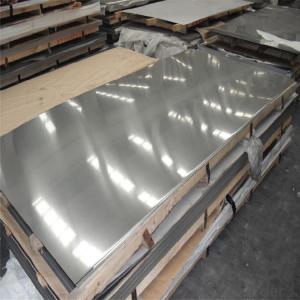

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does stainless steel contribute to the production of medical implants?

- Stainless steel contributes to the production of medical implants primarily due to its exceptional properties such as corrosion resistance, high strength, biocompatibility, and ease of sterilization. These qualities make stainless steel an ideal material for manufacturing various medical implants like joint replacements, bone plates, screws, and dental implants.

- Q: What are the different surface finishing techniques used for special steel?

- Some of the different surface finishing techniques used for special steel include electroplating, powder coating, galvanizing, passivation, and mirror polishing.

- Q: What are the challenges in forging special steel?

- Forging special steel poses several challenges, primarily due to its composition and properties. One challenge is achieving the desired microstructure and alloy distribution throughout the steel during the forging process. Special steels often contain complex alloys, which can be difficult to evenly distribute and maintain during forging. Another challenge is controlling the temperature and heat treatment processes to avoid any detrimental effects on the steel's mechanical properties. Special steels are sensitive to temperature changes, and improper heating or cooling can lead to structural weaknesses or loss of desired properties. Additionally, forging special steels may require specialized equipment and techniques to accommodate their unique characteristics, making the process more intricate and demanding.

- Q: What are the properties of high-temperature steel?

- High-temperature steel possesses several key properties including excellent strength, oxidation resistance, and thermal stability. It can withstand extreme temperatures without losing its structural integrity, making it suitable for applications such as power generation, aerospace, and industrial processes. Additionally, high-temperature steel exhibits low thermal expansion and good creep resistance, ensuring dimensional stability even under prolonged exposure to high temperatures.

- Q: What are the different methods for electroplating special steel?

- There are several methods for electroplating special steel, including electroless nickel plating, gold plating, silver plating, and zinc plating. Each method involves immersing the steel in a solution containing the desired plating material and passing an electric current through the solution to deposit a layer of the plating material onto the steel surface. These methods can enhance the appearance, corrosion resistance, and durability of special steel products.

- Q: What are the advantages of using special steel over other materials?

- There are several advantages of using special steel over other materials. Firstly, special steel has higher strength and toughness, making it more durable and resistant to wear and tear. Secondly, it offers excellent corrosion resistance, preventing rust and extending the lifespan of the product. Additionally, special steel can withstand extreme temperatures, making it suitable for applications in various industries. Moreover, its versatility allows for easy customization and shaping, meeting specific design requirements. Lastly, special steel is known for its high recyclability, making it an environmentally friendly choice.

- Q: What are the requirements for special steel used in transportation infrastructure?

- The requirements for special steel used in transportation infrastructure include high strength and durability, resistance to corrosion and fatigue, excellent weldability, and the ability to withstand extreme temperatures and environmental conditions. Additionally, it should meet specific standards set by regulatory bodies to ensure its safety and reliability in supporting and maintaining transportation structures such as bridges, railways, and highways.

- Q: What are the properties of electrical resistance steel?

- Electrical resistance steel is characterized by its high resistivity, which means it offers high resistance to the flow of electric current. It also exhibits good electrical conductivity, ensuring efficient transmission of electric power. Additionally, electrical resistance steel typically has a low temperature coefficient of resistance, meaning its resistance does not change significantly with temperature fluctuations. These properties make it suitable for various applications, such as in electrical resistors, heating elements, and electrical wiring where controlled resistance and durability are required.

- Q: What are the properties of low alloy steel?

- Low alloy steel is characterized by its composition, which contains a smaller amount of alloying elements compared to other types of steel. These alloys typically include elements such as nickel, chromium, molybdenum, and vanadium. The properties of low alloy steel include increased strength, improved toughness and hardenability, better corrosion resistance, and enhanced wear resistance. Additionally, low alloy steel offers excellent weldability and malleability, making it suitable for various applications in industries such as automotive, construction, and manufacturing.

- Q: What is the difference between stainless steel and special steel?

- Stainless steel is a specific type of steel that contains a minimum of 10.5% chromium, which forms a protective layer on its surface, making it highly resistant to corrosion. On the other hand, special steel refers to a wide range of alloy steels that are specifically designed for certain applications or have unique properties, such as high strength, heat resistance, or electrical conductivity. While stainless steel is known for its corrosion resistance, special steel encompasses various types with different compositions and characteristics to meet specific industrial requirements.

Send your message to us

Cold Rolled 2B 304 Stainless Steel Metal Sheet Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords