Cold forming mill machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

used to open and level rolled plate, entry the plate into forming machine, and bend to required shape in cold state by rollers.

According to different products, cold forming steel mill is grouped into square pipe mill, steel sheet pile unit, and other units.

Square pipe mill mainly products square and rectangular pipes, using “directly forms to square” technology, equipped with high-frequency induction welder, it can realize one set roller producing all specifications of square and rectangular pipes. Our company can produce square pipe mill the spec. is from square 200mm to 500mm.

Steel sheet pile unit is a specified unit in manufacturing steel sheet piles by taking use of continuous bit by bit flexible forming technology.

Other units can product U-steel, C-shape steel and many other shape steels by changing rollers.

Technical process:

Uncoiling →Hydraulic shear and cross-welding→ Delivering machine →Vertical accumulator→ Pinching and leveling machine →Forming→Flying saw →Runway → Material reverse →Packing → Stoting.

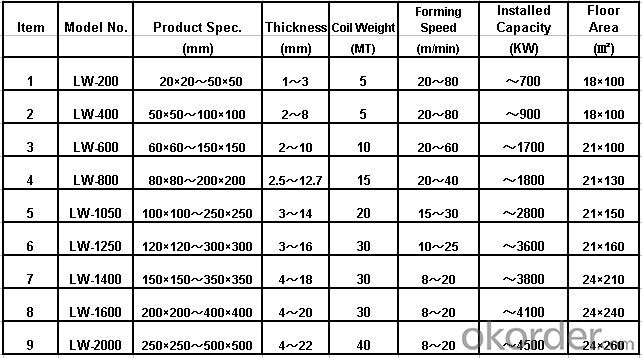

Cold forming steel mill model list:

- Q: A roll forming machine, rolling out of the length is always not up to a fixed size, not too small, that is, more than that, what is the cause?

- Maybe there is something wrong with that roller. It rolls out of the wrong angle and the size will be out of order.

- Q: What is rolling forming processing?

- A special rolling tool is used to exert certain pressure on the surface of the workpiece so as to make the surface metal flow.

- Q: Improvement in rolling forming process

- It is difficult to control the rolling process and can cause waste easily.

- Q: Introduction of roll forming process

- With the progress of technology and the development of production, more and more attention has been paid to the roll forming process.

- Q: What kind of material and what heat treatment are used for pressing roller (molding, feeding, cutting force, heavy load, heavy load) of sheet steel rolling machine?

- Use 40Cr or 20Cr, Cr12.Cr12MoV, quenching and tempering treatment, think of hardness, high point, carburizing, nitriding, and consider adding lubrication device to extend its service life

- Q: What is the surface rolling forming machine process?

- Due to the rolling surface of metal plastic deformation, so that the surface microstructure of cold hardening and grain refinement, forming a dense fibrous, and the formation of residual stress, hardness and strength, so as to improve the surface wear resistance, corrosion resistance and compliance.

- Q: Process mould for rolling forming process

- A movable wire plate, made of the same fixed wire plate, for relative reciprocating motion. Roll forming is the design of different structures on the plate rolling on the workpiece. Roll out all kinds of thread, convex ring, knurling, end chamfering, groove with different width and thickness as well as other required shapes.

- Q: Material and equipment for roll forming process

- The most common type of roll forming is reciprocating flat wire twisting machine. Therefore, for the manufacturers of cold heading machines and screw rolling mills, the design of rolling dies is only a matter of design.

Send your message to us

Cold forming mill machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords