C-Section Roll Forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of C-Section Roll Forming Machine

General Information of C-Section Roll Forming Machineof C-Section

Roll Forming Machine

This C-Section roll forming machine is full-automatically controlled by PLC, the whole hydraulic transmission, drive hydraulic oil jar carry out and shear through centre pump station towards the hole,hydraulic pressure motor transmit power as main transmission. We can produce according to your drawings.

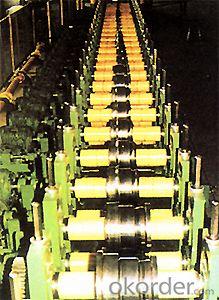

This roll forming machine is the special high speed roll forming machine for steel sheet cold-form industries. It has pressing system and can continuous form the steel sheet according to customer’s requirement, automatically cut to length. This equipment has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good look and so on.

Specifications of C-Section Roll Forming Machine

1 use to different sheet product

2 high quality and competitive price.

3 easy operation

4 With fewer people, save space

Working flow

Decoiling→feeding steel strip →sheet leveling→punching to length→Cut to length →roll forming →run out table

Technical parameter

Item |

Parameter | |

Suitable material |

Type |

galvanized sheet |

Thickness |

0.4-0.8 (mm) | |

Yield stress |

235-345(Mpa) | |

Machine material |

Hole puncher |

Cr12 quenched |

Roller |

GCr15 quenched | |

Cutting Blade |

Cr12 quenched | |

Power Requirement |

Type |

380V/3PH/50HZCustomize |

Main Motor |

15kw | |

Hydraulic |

7.5kw | |

Hydraulic Cantilever

De-coiler |

Type |

Hydraulic automatic |

Max Capacity |

3000kgs | |

Suitable OD |

1200mm | |

Suitable ID |

508/610mm | |

Max Width |

500mm | |

Motor Power |

4.0kw | |

Hydraulic Power |

2.2kw | |

Forming Speed (Excludes cutting & punching) |

20-25m/min | |

Forming Stand |

About 14 group | |

Transmission |

Chain,sprocket | |

Type of Cutting |

length-set cutting | |

Control System |

Mitsubishi PLC& transducer | |

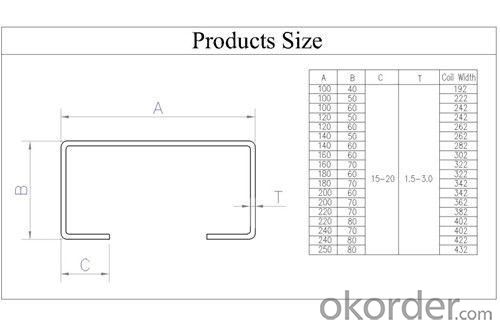

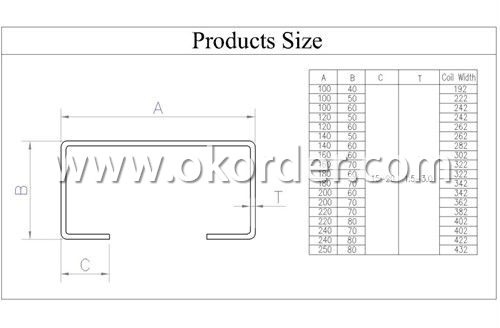

Products Size of C-Section Roll Forming Machine

Packaging & Delivery of C-Section Roll Forming Machine

| Packaging Detail: | Bare packing,with computer control cabinet is to be boxed. This line can be put into one 20feet container. |

| Delivery Detail: | 35 working days after receiving advance payment. |

- Q: A roll forming machine, rolling out of the length is always not up to a fixed size, not too small, that is, more than that, what is the cause?

- According to my experience, there should be a problem with the boot encoder (also known as the digital wheel). Thank you. I hope I can help you.

- Q: What is rolling forming processing?

- A special rolling tool is used to exert certain pressure on the surface of the workpiece so as to make the surface metal flow.

- Q: Improvement in rolling forming process

- Can not meet the slender rod, thin-walled tubes and other rigid parts of the processing.

- Q: Introduction of roll forming process

- With the progress of technology and the development of production, more and more attention has been paid to the roll forming process.

- Q: What kind of material and what heat treatment are used for pressing roller (molding, feeding, cutting force, heavy load, heavy load) of sheet steel rolling machine?

- Use 40Cr or 20Cr, Cr12.Cr12MoV, quenching and tempering treatment, think of hardness, high point, carburizing, nitriding, and consider adding lubrication device to extend its service life

- Q: What is the surface rolling forming machine process?

- Different from cutting, mirror rolling is a kind of plastic processing. Not only is the rolling workpiece surface roughness moment can reach Ry0.1-0.8 m, and the wear resistance of the surface hardening process has been improved at the same time fatigue strength also increased 30% advantages in cutting can not get.

- Q: Process mould for rolling forming process

- A movable wire plate, made of the same fixed wire plate, for relative reciprocating motion. Roll forming is the design of different structures on the plate rolling on the workpiece. Roll out all kinds of thread, convex ring, knurling, end chamfering, groove with different width and thickness as well as other required shapes.

- Q: Material and equipment for roll forming process

- The most common type of roll forming is reciprocating flat wire twisting machine. Therefore, for the manufacturers of cold heading machines and screw rolling mills, the design of rolling dies is only a matter of design.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2007 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 23.41% Eastern Europe 20.29% Southeast Asia 16.91% Mid East 11.68% Africa 11.00% South America 8.74% North America 4.30% Eastern Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

C-Section Roll Forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords