High-speed Tile Forming Machine Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High-Speed Tile Forming Machine Line

Brand Name: HBKDMACHINE

Company Profile:

HBKDMACHINEis a wholly private-owned enterprise that manufactures roll-forming machines and related products for the sheet metal industry. Since established in 1996, our factory has developed machinery and production methods to meet our customers' increasing demands for profitability and new business opportunities.

We can supply a wide range of machines such as roll forming machines for metal roof tiles, wall sheets, C-shaped purlines, Z-shaped purlines, and peculiar shaped purlines, glazed tile forming machines, highway guardrail forming machines, sandwich panel roll forming machines, press brakes and shearing machines. A large number of machines are exported to foreign countries such as Canada, South Korea, Sri Lanka, and Outer Mongolia. All of our products are popular both at home and abroad.

Our professional technicians and skilled workers ensure high quality products for our customers with perfect quality management and testing systems. We're always able to meet your customized needs. From basic economical roll formers to the most complex, we fashion a solution to meet your company's production goals and budgets.

"Increasing your productivity and profitability with our efficient and reliable machines that offer high-quality output" and "On-time delivery, customized design, competitive prices and satisfied after-sales services" are our promises to you.

We sincerely welcome both domestic and international friends to cooperate with us.

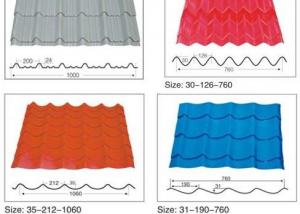

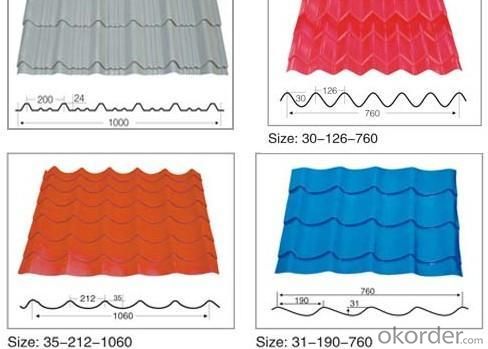

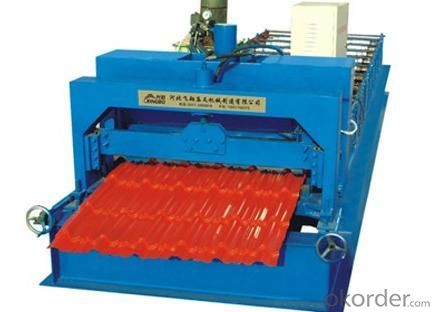

General Information of High-speed Tile Forming Machine Line

This Machine is for producing metal roofing tiles,widely used in roofing industry. The max forming is speed 15 meters per minute.

We can design and produce according to your drawings.

Technical Data Of High-Speed Tile Forming Machine Line

|

Main Motor Power |

5.5KW |

|

Hydraulic Motor Power |

2.2KW |

|

Roll Stand |

18 |

|

Uncoil |

1000mm |

|

Thickness |

0.4-0.8mm |

|

Material Of Cutter |

Cr12 |

Packaging & Delivery Of High-Speed Tile Forming Machine Line:

export standard package for container

Terms:

1.Delivery: in stock

2.Delivery date:within 30 working days after receiving deposit

3.Products wattanty: 12month, and we will provide the technical support for whole life of the equipment.

- Q: A roll forming machine, rolling out of the length is always not up to a fixed size, not too small, that is, more than that, what is the cause?

- According to my experience, there should be a problem with the boot encoder (also known as the digital wheel). Thank you. I hope I can help you.

- Q: What is rolling forming processing?

- Ironing the surface of the workpiece with a raised micro wave crest to fill the concave micro troughs, thus changing the distribution of the peaks on the surface, and obtaining smaller surface roughness values.

- Q: Improvement in rolling forming process

- It is difficult to control the rolling process and can cause waste easily.

- Q: Introduction of roll forming process

- Not only threaded fasteners industry applications, automobiles, bicycles and other industrial sectors also use rolling forming process, processing complex shapes of parts.

- Q: What kind of material and what heat treatment are used for pressing roller (molding, feeding, cutting force, heavy load, heavy load) of sheet steel rolling machine?

- Use 40Cr or 20Cr, Cr12.Cr12MoV, quenching and tempering treatment, think of hardness, high point, carburizing, nitriding, and consider adding lubrication device to extend its service life

- Q: What is the surface rolling forming machine process?

- Due to the rolling surface of metal plastic deformation, so that the surface microstructure of cold hardening and grain refinement, forming a dense fibrous, and the formation of residual stress, hardness and strength, so as to improve the surface wear resistance, corrosion resistance and compliance.

- Q: Process mould for rolling forming process

- Press forming is an advanced processing technology, and its remarkable characteristics have been paid attention to by the automobile industry at home and abroad.

- Q: Material and equipment for roll forming process

- Rolling process is a cold forging process, which can be used for rolling and forming a lot of materials. Among them, low carbon steel is a material commonly used in rolling forming, and non-ferrous metal is more suitable for roll forming.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | 28.71% Domestic Market 16.39% Eastern Europe 14.26% North America 14.26% Southeast Asia 14.26% Africa 7.13% South America 4.99% North America |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 8-10 people |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High-speed Tile Forming Machine Line

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set set

- Supply Capability:

- 100 set per month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords