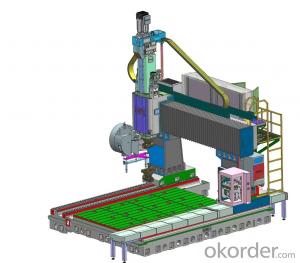

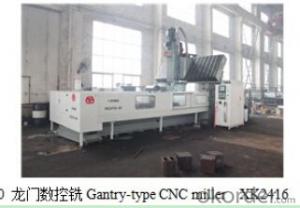

CNC HORIZINTAL MILIING GANTRY MACHINE CERTER

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Small footprint, low energy consumption, non moving tabletop, fast movement speed, and convenient maintenance;

2. Complete one-time pentahedral processing of the product, more effectively ensuring the accuracy of the product; (Hexahedron can be achieved according to customer needs)

3. The installation of a W-axis motion axis on the gantry crane increases the Z-axis travel while also improving machining accuracy and efficiency;

4. The gantry crane is mainly used for heavy cutting processing of large, structural, and shell components in industries such as automobiles and aviation;

5. The 420mm ultra strong square ram is made of FCD600 material grade.

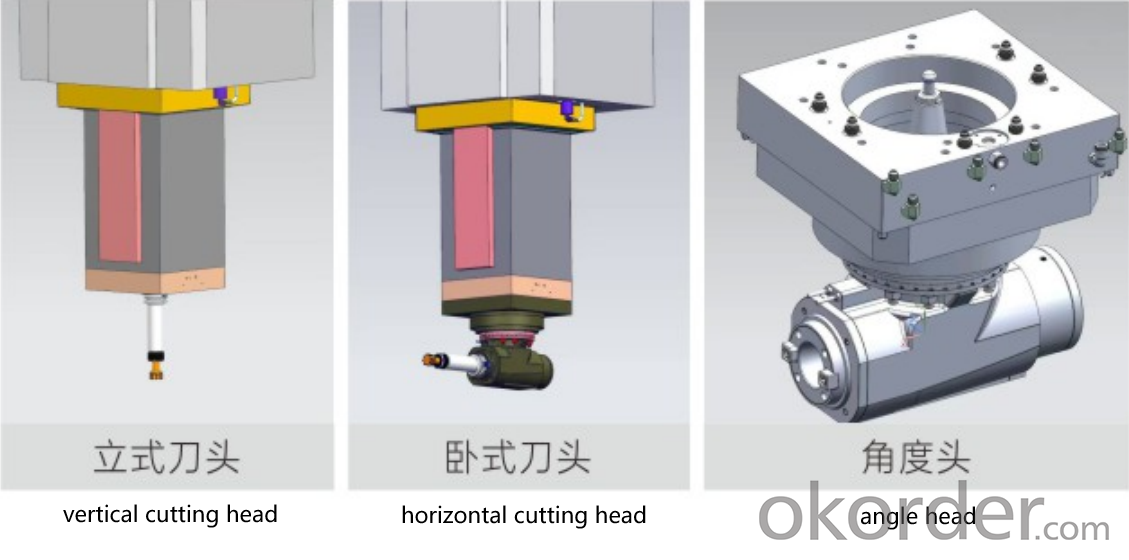

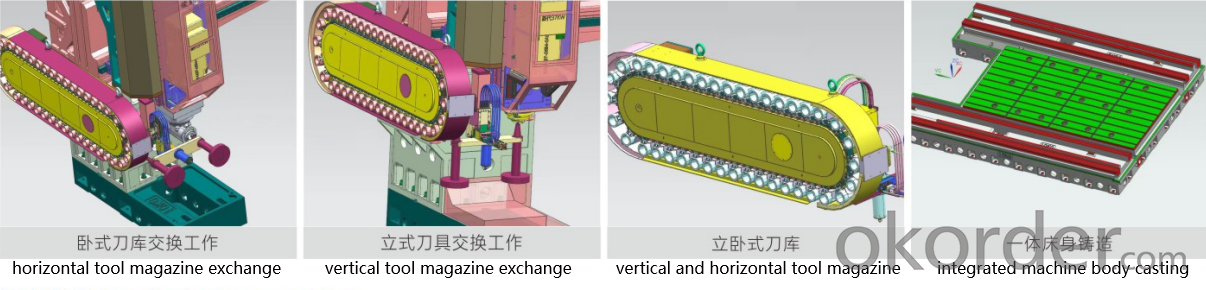

Main Component Characteristics

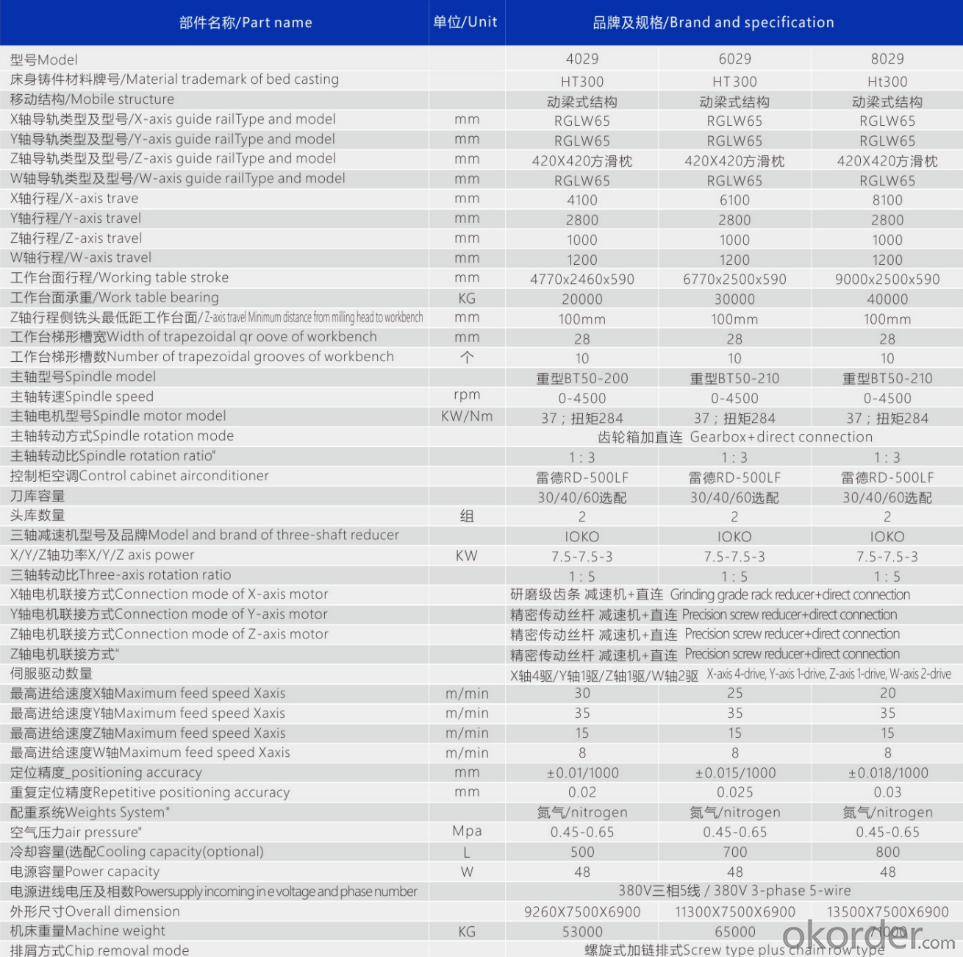

Technical Parameter

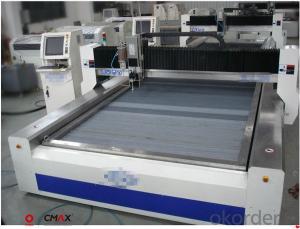

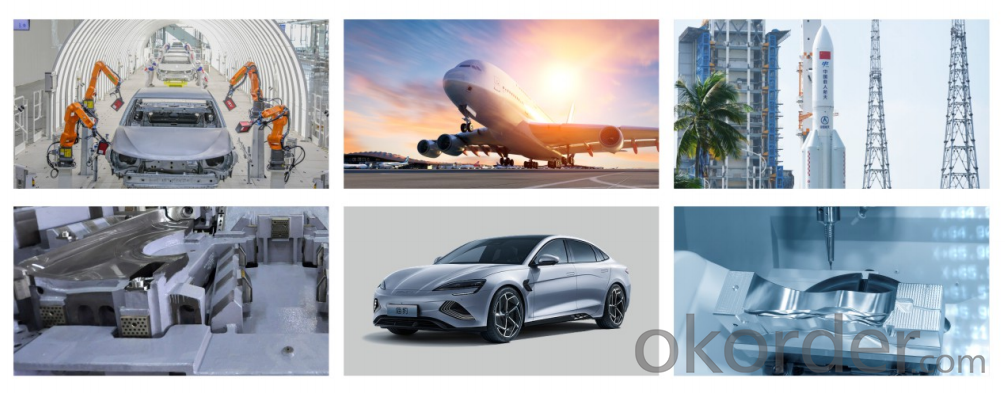

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Package

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-180 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: The difference between the milling machine and the machining center

- Turning and milling machine: also known as 5-axis double power head processing center.

- Q: Machining center with twist drill bit cast iron speed how much feed how appropriate

- To remind that, calculated in accordance with the theory, to be tested in order to find the most appropriate speed and feed.

- Q: Will the CNC machining center and computer gong What is the difference

- CNC machine operation and monitoring all in this CNC unit to complete, it is the brain of CNC machine tools.

- Q: What is the M code of the Mitsubishi Machining Center?

- But I have to do is FANC bedroom processing center, he used G10L_P_X_Y_Z_ to set the coordinates of the L and P on behalf of the

- Q: What is the machining center?

- Machining center is a high degree of mechanical and electrical integration of products, workpiece clamping, the CNC system can control the machine according to different processes automatically select, replace the tool, automatic knife, automatically change the spindle speed, feed, etc., can be completed drilling,

- Q: Japan vertical processing center Makino, Sen fine, Mazak, brother ....... Which brand of the best? Which is the most expensive price? Comparison of the various brands!

- Li Jia, lying plus the best is Makino, Toshiba, Mitsui.

- Q: Mechanical processing, I was open CNC machining center! I would like to ask this f is what! F40 stands for something! How to calculate the amount of feed!

- The choice of feed rate during finishing is to take into account the roughness of the process.

- Q: CNC machining center alarm 1005

- Re-emergence of the alarm I am in the buoyancy buoyancy feel some hot What is the reason ...

- Q: Machining Center Large Area Aluminum Plane Machining

- Such a large plate flatness of 0.1 you do not have to control it, the basic can not, we have previously processed 1000 * 700 board, directly to buy imported aluminum, factory warranty within 0.05, back to the professional leveling after leveling the company leveling

- Q: Vertical machining center lubrication system

- the flow of compressed air to blow the oil into small oil droplets, attached The oil film is formed on the pipe wall, and the oil film flows along the pipe wall with the direction of the air flow. The thickness of the oil film is gradually thinned during the flow, but it does not condense.

Send your message to us

CNC HORIZINTAL MILIING GANTRY MACHINE CERTER

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches