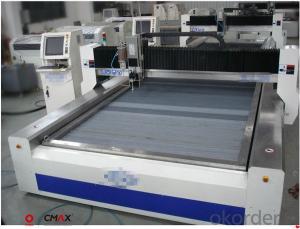

Vertical Machine Centre

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2566 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden package |

| Delivery Detail: | 50days |

Specifications

1.High efficient

2.Easy for operation

3.ATC

4.CE certificate

Machine features:

1) the main machine components(machine bed ,sliding sadder ,worktable)have adopted the structure of thermal symmetry and thin-walled

main stock with multi-layer ribs. arch” shape column with high rigidity goes through optimized treatment by finite element analysis to guarantee

the best rigidity;

2) the adoption of C3 grade precise ball screws and the use of special bearing on the ball screw with pre-pull treatment as well as laser

detective compensation have ensured the rigidity and precision.

- Q: Which big god gets advice, cnc processing center g code g28g98g99 in the end what is the meaning. To be detailed. Have labor Thank you

- 91G30Z0 (Z axis back to the library 0 zero, the height of the knife, the point of some machines and machinery 0 points coincide)

- Q: How does the law processing center use online processing?

- according to the previous serial number 0001 input 1 call 0001 program

- Q: Kneel for the hair that processing center milling round program

- the depth of your set, and then 12 milling cutter finishing, so easy to do more specific as follows :

- Q: What is the M code of the Mitsubishi Machining Center?

- But I have to do is FANC bedroom processing center, he used G10L_P_X_Y_Z_ to set the coordinates of the L and P on behalf of the

- Q: Shanghai area 4 800 or so processing center 20 hours a day operation, a year of gross profit in the number of how much ah

- the price is also very different, and your machine's operating rate is not so high.

- Q: The Advantages and Disadvantages of Carving Machine and Machining Center

- It is suitable for large workpiece with strong cutting.

- Q: Mechanical processing, I was open CNC machining center! I would like to ask this f is what! F40 stands for something! How to calculate the amount of feed!

- F40 represents the cutting feedrate of the tool relative to the workpiece at 40 mm / min when performing G01, G02, G03 and hole fixing cycles.

- Q: What is the difference between CNC lathes and CNC machining centers?

- CNC lathe general processing products are not too big, big turn up centrifugal large folder can not clip, but the lathe processing speed, suitable for small products, large quantities of processing, and processing center for processing small batch, complex product processing

- Q: Comparison of CNC milling machine and CNC machining center machine differences

- CNC milling machine and processing center is the same: the processing center is also a computer numerical control system (CNC), servo system, mechanical body, hydraulic system and other components.

- Q: Where is the difference between G43 and G44?

- G43 and G44 are tool length compensation function. G43 is generally used to compensate, G44 is anti-compensation, the normal processing technology, there is no need to use the tool length anti-compensation significance. Remember G43 on it.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | North America Eastern Europe Southeast Asia Mid East Western Europe |

| Company Certifications | ISO9001:2008 English Version;ISO90001:2008;CE Certificate;CE Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | English, Chinese |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

Vertical Machine Centre

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 2566 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords