Auto Polishing Peeling and Grinding CNC Machine JN-T8/D8/D10 for Prouding Faucets

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

We are supplying new generation CNC peeling machine which is high-precision, high-efficiency and energy-saving. It has a great improvement on the traditional grinding process.

The machine adopts gantry type body and it covers an area of only 8m², can process 8 faucets at a time, and the brass recovery rate is 100%.The casting bodies can be processed directly on this machine after the excess parts are cut off.This machine can remove all draft surfaces on products. Finish the surface up to 220-240 mesh which can replace the rough grinding process.

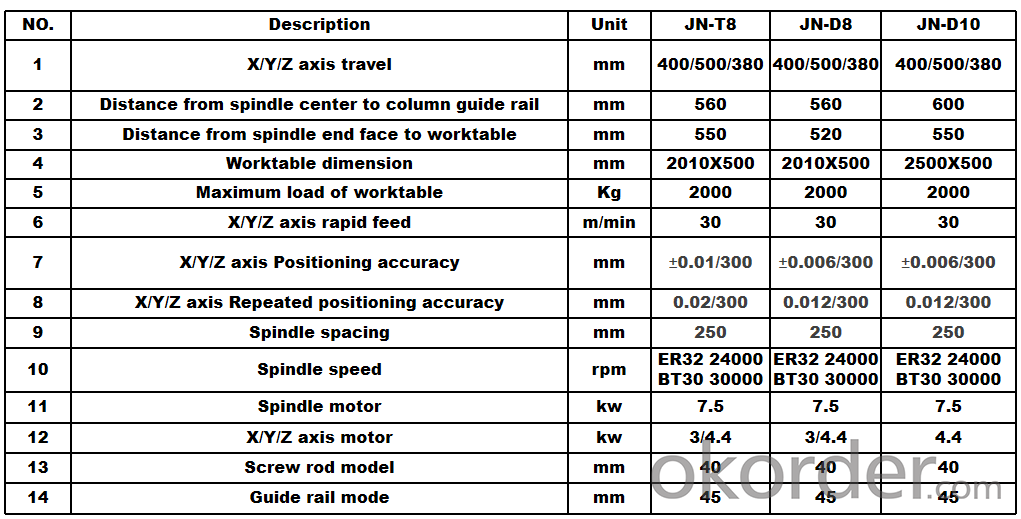

Model:JN-T8、JN-D8、JN-D10

System option:Siemens、Mitsubishi、Syntec

Technical Parameter

Package

Global Sales Market

International Partner

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: Processing center models are what? How to classify the various models are on behalf of what does this mean?

- Processing center discrete and lying plus, gantry machining center, CNC boring and milling machining center

- Q: What is the meaning of the R value in the machining center program?

- When the hole is machined with a fixed cycle such as G81, R is the point R, which is the position where the Z axis is automatically moved up after the completion of the single hole machining.

- Q: Machining center milling depth of 10 mm for planar programming

- Fagordnc software. If you want a computer to communicate with multiple CNC machines at the same time, use http://www.multi-dnc /trial/m-disk.exe.

- Q: How does the law processing center use online processing?

- according to the previous serial number 0001 input 1 call 0001 program

- Q: What is the difference between gantry milling machine and gantry processing center? Mainly from the function and processing objects to explain the difference.

- So that the latter when the processing can be automatically replaced.

- Q: How to process taper holes with machining centers?

- Features slow, the accuracy I have not tried taper to eat, here dare not jump to comment.

- Q: What is the machining center?

- Which greatly reduces the workpiece clamping time, measurement and machine adjustment and other auxiliary process time, the processing of the shape is more complex, high precision requirements, frequent replacement of parts with good economic results.

- Q: The Advantages and Disadvantages of Carving Machine and Machining Center

- Processing Center: Hong Kong and Taiwan, Guangdong area called the computer gong, with a knife and automatic tool changer of a highly automated multi-function CNC machine tools.

- Q: What is the use of the processing center?

- The machining center is equipped with a magazine, with automatic tool change function, the workpiece after a clamping operation of multi-process CNC machine tools.

- Q: What is the use of the G94 command?

- After using the G95 command, all feeds are in mm / r units, ie F100 means the spindle is rotated by 100 mm

Send your message to us

Auto Polishing Peeling and Grinding CNC Machine JN-T8/D8/D10 for Prouding Faucets

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches