Horizontal Maching Center Model HMC630/800 with Siemens/Fanuc/Mitsubishi System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

The horizontal machining center has inverted T structure, high spindle speed, strong rigidity and large torque. This series of machine tools has

perfect performance, stable accuracy, and reciprocating exchange of worktables. It is suitable for processing various types of box parts and two-

dimensional and three-dimensional surfaces. It is the key equipment for processing box parts in machinery, automobile, ship, textile machinery,

printing machinery, agricultural machinery and other industries.

System option:Siemens / Mitsubishi / Fanuc

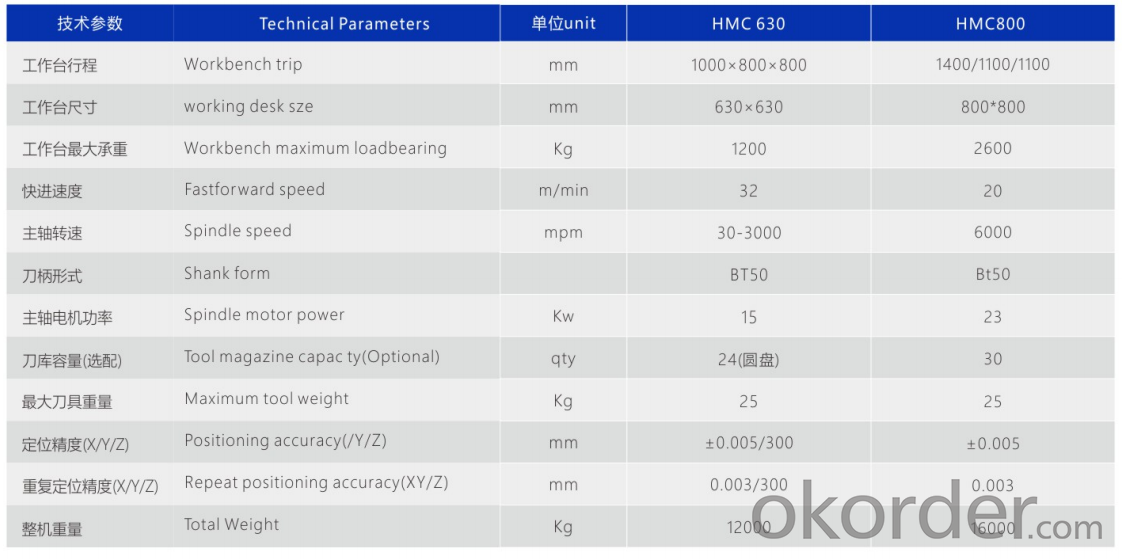

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: Will fanuc processing center length compensation how to use? Can you give an example to explain!

- Such as the use of the workpiece workpiece coordinate system G54 X Y knife does not introduce the Z data to pay special attention

- Q: Machining center in the G98, G99 What does it mean?

- G98 is to return to the initial plane, G99 is to return to R points: 1. G90G00G54X0Y0; G43H1Z50M3S500; G98G81Z-20R5F100; (after processing the tool back to the Z50 position, G98 can ignore the write, the system will be the default) X50Y50;

- Q: Machining center with an end mill milling side of the surface when the collapse is caused by what causes.

- the knife hole will be attached to a layer of misty film, when the knife knife folder are deposited on the film, Difficult to firmly grip the handle, the processing end mill is easy to loose drop. So the end mill before clamping, should first end knife handle knife hole with cleaning fluid cleaning,

- Q: Machining center milling depth of 10 mm for planar programming

- Ug can only be generated according to the machine after the machine for the machine to produce nc program files. Dedicated communication software to complete the computer and machine data transfer between the majority of ordinary CNC machine comes with the communication port with the computer com serial port for online communication.

- Q: NC, CNC, MC What does it mean? Some say CNC and MC are machining centers, halo. The The Which are two-dimensional or three-dimensional?

- The control system can logically process a program with control codes or other symbolic instructions and decode it so that the machine moves and processes the part.

- Q: Machining center rail form and its characteristics?

- So hard-track load-bearing capacity is several times the line. Commonly used in large and medium-sized or giant processing center.

- Q: Where is the difference between G43 and G44?

- I do not know that I do not understand, if do not understand the words, plus my QQ 121802855 I was CNC machining center programmer.

- Q: 850 processing center servo motor how many watts

- The general 850 breakdown X Y 10 NM to 18NM or less it.

- Q: What is the difference between a vertical machining center and a horizontal machining center? What are the features?

- But the height of the column and the tool changer limit, can not handle too high parts, in the processing cavity or concave surface, the chip is not easy to discharge, serious damage to the tool, damage the machined surface, affecting the smooth processing

- Q: Are there any differences between CNC and machining centers and CNC milling machines?

- Colleagues are judged by the actual use of the function.

Send your message to us

Horizontal Maching Center Model HMC630/800 with Siemens/Fanuc/Mitsubishi System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches