Drilling and Tapping Center CNC Machine Model T6 with Syntec System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

High Precision

1、Spindle drive adopts high response O&R spindle, high speed up to 20,000 rpm.

2、Adopting high grade spindle ensures high reliability, long life, low noise, low vibration, high precision and other advantages of the spindle.

Strong rigidity

1、The frame is made of high-quality resin sand wear-resistant castings, strong bones, large columns, base, honeycomb structure; annealed, long-lasting and not deformed.

2、Three-axis line rail adopts on the silver steel strong precision high-speed mute guide, can withstand high-speed, high-precision cutting processing.

System option:Syntec

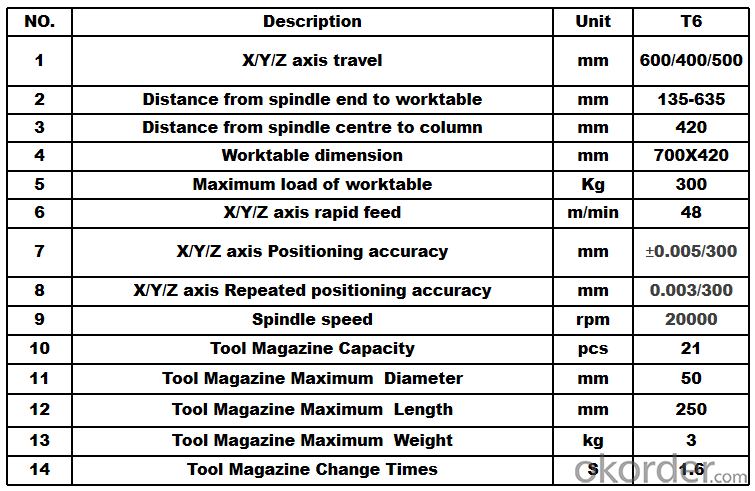

Technical Parameter

Package

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q: What is a few axes? Like the XYZ three-axis machining center?

- CNC lathes, turning centers, is a high-precision, high-efficiency automated machine tools.

- Q: How is the center of the processing center?

- To the safe position and then close to the other end of the Y-Y to the beginning of the first hand wheel speed to 0.1 speed close to the workpiece concentric when the hand wheel speed adjusted to 0.01 slowly close to the workpiece to see the edge of the erection of the edge again

- Q: Can the machining center rotate the coordinate system?

- The coordinate system rotation function refers to the programmed graphics being rotated.

- Q: H, l, p, s, t, f, what is represented in the machining center

- The second and third memories are not too clear and rarely used

- Q: Processing area of the processing center

- Box type of workpieces such as the general requirements of the workpiece are more than the hole and the plane of the processing, positioning accuracy requirements, processing in the processing center when a fixture to complete the ordinary machine 60% to 95% of the process content.

- Q: How to set up the CNC vertical machining center

- The difference between the two values, and then one end of the beat, and finally make the two values the same, to find the right.

- Q: The difference between milling and reverse milling in cnc CNC machining center

- The direction of rotation of the contact between the milling cutter and the workpiece is the same as that of the workpiece feed direction, and vice versa.

- Q: 2.5 axis machining center and 3-axis machining center What is the difference

- The machining center is a machine tool with B-axis linkage and C-axis linkage which can be used for turning and milling. It can be said that all or most of the machining of a part can be completed on the above-mentioned turning and milling machine, so it is also called small production line

- Q: Japan vertical processing center Makino, Sen fine, Mazak, brother ....... Which brand of the best? Which is the most expensive price? Comparison of the various brands!

- Li Jia, lying plus the best is Makino, Toshiba, Mitsui.

- Q: What are the common processing centers in China?

- Processing center is equipped with a knife library, with automatic tool change function, the workpiece after a single folder for multi-process processing CNC machine tools.

Send your message to us

Drilling and Tapping Center CNC Machine Model T6 with Syntec System

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches