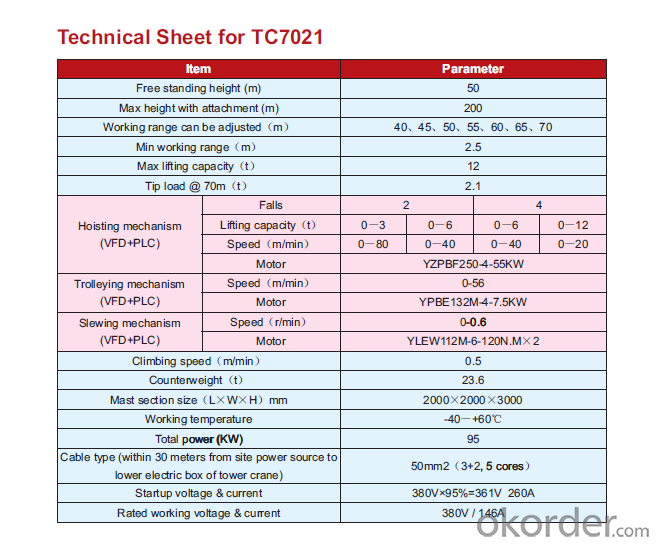

CMAX Tower Crane TC 7021 Construction Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CMAX Tower Crane TC 7021 Construction Machine

Product Description:

Descriptions of our tower crane:

1, the topless tower crane reduce the dismounting requirements, lower weight, low mounting height, dismount each mast at a time in the air, save the labor cost, safety and fast.

2, it is suitable for crossover work of the cranes, without the tower cap and pull rod, the safety will be increased when there need the crossover work.

3, It is suitable for the special requirement about the height, such as airport nearby, tunnel, workshop ,and the construction site with high-tension cable.

4, It is suitable for the construction site that has the requirement about the crane boom, it can be used as internal climbing crane in the high-rise buildings, irregular roof or small areas.

5, It is very convenient for dismounting in the restricted construction site, dismount each crane boom at a time by manual.

6, The steel structure of crane boom has long using life and high safety standard.

7, The crane boom is good applicability, high-usage,the design of the topless tower crane boom is easy for realizing the serialization and standardization. Reduce the design and making cost.

8, Low design cost, short cycle, can much better satisfy the multiple demands of the customers.

Advantage of our tower crane:

1, boom relief Angle is big, greatly widened the equipment capacity and scope of work.

2,It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation

3, boom stability is good, combination amplitude range.

4, suitable for height have special requirements occasions construction.

5, lifting capacity big, effectively solve the high steel structure construction team crane big lifting capacity requirements.

FAQ;

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

You can put 2 sets of of wheel loaders in one 40HQ container. The spare parts are packed with boxes.

The delivery time is 20 days.

3. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

4.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q: who invented them and why do people make them?

- in Japanese folklore if you fold a 1000 origami cranes you get are granted a wish, usually concerning health/long life. The peace part comes from the story of Sadako Sasaki a victim of the Hiroshima atomic

- Q: As a building gets taller, the crane is raised. How is this done? And when the building is done, how do they get the crane back down?

- they use a process called jumping. iron workers use a special fixture to unbolt the tower and lift the crane up high enough to slide in another section and bolt it down. breaking down of the crane goes in reverse order.

- Q: Where you stand on one leg with your hands up and out to sides.Isn't standing on one leg in a fight leaving you exposed and vulnerable? What techniques can you actually do from that stance anyway (other than jumping up and kicking with the leg that was on the ground like the karate kid).

- Kung Fu Crane Stance

- Q: I'm a bit confused as to what happened to him. I guess I skimed a bit at a certain important part of the book. When Seneca Crane's name was written on the dummy during training, why did the people gasp at the name written in berry juice? What happened to him? PS. I am at the begining of Mockingjay. So no spoilers please. (:

- In the end of the first book, he was put in a room with a bowl in the middle. In the bowl, there were berries. Very deadly berries. This is significant because in the arena, Peeta and Katniss threatened the Capitol that they would eat them and kill themselves. If that happened, there would be no victor. President Snow wanted Seneca Crane to kill them. But Seneca Crane let there be two victors, instead of one or none. So, back to the point. Seneca Crane was punished because he couldn't listen to the president's orders. So, he was put in a room with no food, water, etc. If he got hungry he, he had to eat the berries. So, he died. I don't know how you missed that, but I hope this helps! :) I LUV U PEETA!

- Q: Crane lifts a 600-kg bin with an initial acceleration of 2 m/s^2. Determine the force in each of the supporting cables due to this motion.?

- F = ma Assume the crate is uniformly loaded, both cables will carry the same force F(AB)(4/5) = (600/2)(9.8 + 2) F(AB)(4/5) = 3540 F(AB) = 4425 N F(BC) = 4425 N F(B-Crane) = 600(9.8 + 2) F(B-Crane) = 7080 N As a form of exchange, please remember to vote a Best Answer from among your results. This is not the same as like or thumbs up which are also nice and do boost points, but only after asker awards initial points with their vote.

- Q: the highest ranking American serviceman, at least in the so called prison camp

- no, he was brutally murdered

- Q: Ok I got these huge mosquito things in my house and found out they are crane flies. I got up this morning and there are several hanging from my ceiling on a long single strand of silk or web. Is this unusual? Its really weird.

- Probably just harvest man or a cellar spider making a web. You might have just mistaken them.

- Q: I am looking for what the breeding season is for sandhill cranes?

- Mid-April to mid-June is breeding season for Florida Sandhill cranes lasts from December-June. For most other cranes, like those here in the midwestern U.S., the breeding season is March and April. I'm fortunate enough to live not too far from the Jasper Pulaski Fish and Wildlife Area where the Sandhill Cranes migrate every spring and fall. I always go to see this spectacular event.

- Q: does it only carry thousand of pounds stuff or wat?? for science project??

- A CRANE USES MECHANICAL POWER ,PULLEYS ,COUNTER WEIGHTS.AND CABLE TO LIFT USING A BOOM IT CAN LIFT SEVERAL THOUSAND POUNDS

- Q: how do cranes get assembled ? on building sites?

- By people.

Send your message to us

CMAX Tower Crane TC 7021 Construction Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords