Plastic Sheets - CMAX Cast Acrylic Sheets Made of 100% Virgin Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

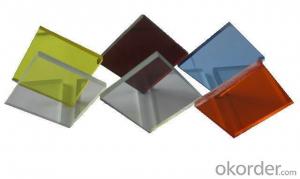

Feature of colorful cast Acrylic sheet

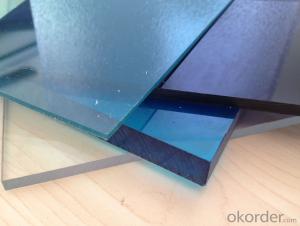

Perfect transparency and the light transmittance up to 93%.

Excellent electrical insulation and light weight.

Good plasticity, easy to process and re-shape.

Strong surface hardness and good weather resistant property

Variety of colour, easy to clean

Applications of colorful cast acrylic sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse, signboard, indicator, display rack.

Vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

colorful cast acrylic sheet Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | colorful cast plexiglass sheet |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | colorful cast plexiglass sheet |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | colorful cast plexiglass sheet |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

- Q: I want to try making my own soccer cleats from scratch. im trying to find a material to use for the bottom / sole plate of the cleat.

- Sorry but they will crush under weight. They do break easily. You can cut them using a hacksaw.

- Q: looking for felxiable mirorred plastic no more than a 1/2 inch ..that i can order online or go to a store in portland oregon and buy in 3 ft sections making a wearable design.. in sliver and gold or black ... any help where to get this would help.. Thanks

- I believe Mylar like balloons are made from is the material you are looking for You can buy it on line or from hydrophonic stores.

- Q: Can plastic sheets be used for costume making?

- Yes, plastic sheets can be used for costume making. They are often used to create various costume elements such as armor, masks, and other structural components. Plastic sheets provide versatility, durability, and can be easily shaped and manipulated to achieve the desired costume design.

- Q: Are plastic sheets resistant to warping or shrinking under heat?

- Yes, plastic sheets are generally resistant to warping or shrinking under heat. However, the specific resistance can vary depending on the type of plastic used and the temperature it is exposed to.

- Q: Can plastic sheets be cut into custom shapes?

- Yes, plastic sheets can be cut into custom shapes using various cutting methods such as laser cutting, CNC routing, or even manual cutting with appropriate tools.

- Q: Do plastic sheets have any impact on insulation efficiency?

- Yes, plastic sheets have an impact on insulation efficiency. Plastic sheets, such as vapor barriers, can help improve insulation efficiency by preventing the transfer of moisture and air through walls or ceilings. They act as a barrier that reduces heat loss or gain and helps maintain a more consistent indoor temperature, thus enhancing insulation effectiveness.

- Q: Can plastic sheets be recycled into other materials?

- Yes, plastic sheets can be recycled into other materials. Recycling plastic sheets involves melting them down, which can then be used to make various products such as new plastic sheets, plastic bottles, or even different types of plastic materials.

- Q: I found the perfect thickness of plastic Delrin in my garage but it's already shaped in an exact circle. The Diameter is 4 inches which is fine because I need 3.89 inch diameter in the pieces I'm cutting. I have approx. 75.3 inches of length of the delrin. Each of the pieces is really thin that I'm creating a mear .03125 inches. I need 324 pieces and a couple to spare wouldn't hurt. Does anyone know how to calculate this or is there a calculator that does this?

- Confusing question, but I think I understand what you need. There are yield calculators out there on the internet, but I will do the math for you. You would get 327 pieces of 4 diameter discs that are .03125 thick. The reason it wouldn't be more is that the saw blade will eat up material in between each cut (about .2 per cut) Just so you know, this job will be VERY difficult to do, so make sure you have proper machinery or take it to a professional. Good luck!

- Q: I have started sewing checkbook covers recently. They seem to need something to stabilize them, and I have been using cardboard. I was wondering if anywhere sells thin plastic sheets (like margarine/yogurt lid thickness) that I could cut to fit. I don't sew through it, it would be removable. Or somewhere online would work too.... or any suggestions to use stuff I already have! Thanks for your help! :)

- Plastic canvas works well for that. Michaels and Hobby Lobby both have it.

- Q: A proton (m= 1.67x10^-27kg) moving at 4.0x10^7m/s shoots through a sheet of foam plastic .25 cm thick and emerges with a speed of 1.5x10^7 m/s A) How long does it take to pass through the plastic?B) What average force retards the proton's motion through the plastic?Hints: Fext T+MVi=MVf Ans: A. 9.09x10^-11s B.4.59x10^-10N

- A) d = Vavg * t 0.0025 m = ?(4.0 + 1.5)e7m/s * t t = 9.09e-11 s B) The hint uses the impulse equation: impulse + initial p = final p F * 9.09e-11s + 1.67e-27kg * 4.0e7m/s = 1.67e-27kg * 1.5e7m/s F = -4.59e-10 N Since the force is against the direction of motion, I think it should have a negative sign; your answer suggests it isn't warranted. Without the hint, you could do acceleration a = Δv / Δt = (1.5 - 4)e7 m/s / 9.09e-11s = -2.75e17 m/s? and then F = m*a = 1.67e-27kg * -2.75e17m/s? = -4.59e-10 N If you find this helpful, please award Best Answer!

Send your message to us

Plastic Sheets - CMAX Cast Acrylic Sheets Made of 100% Virgin Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords