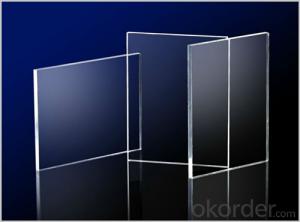

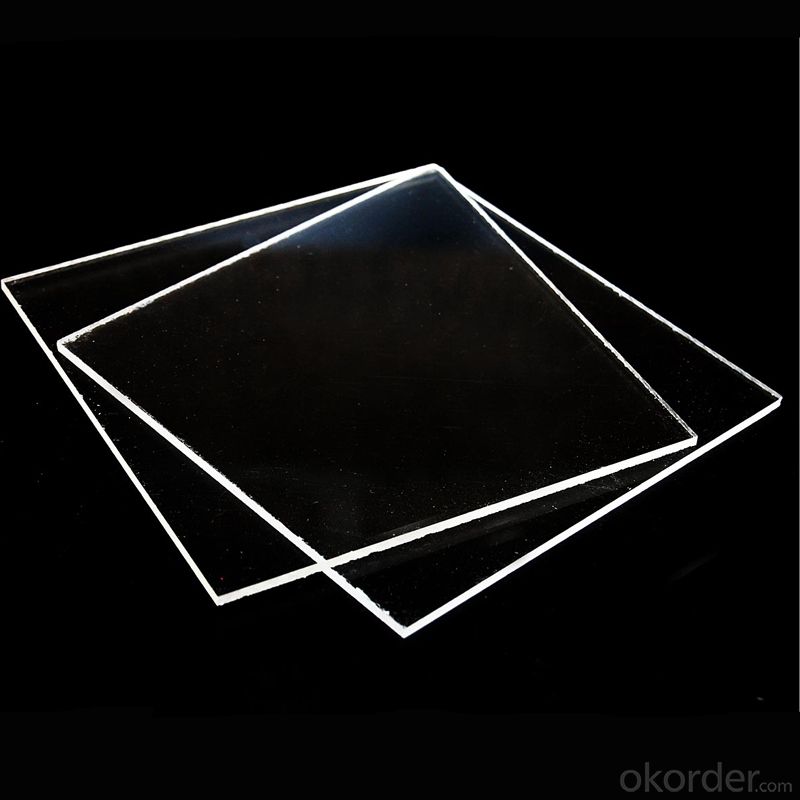

High Quality 100% Virgin Material Clear Plastic Sheets

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

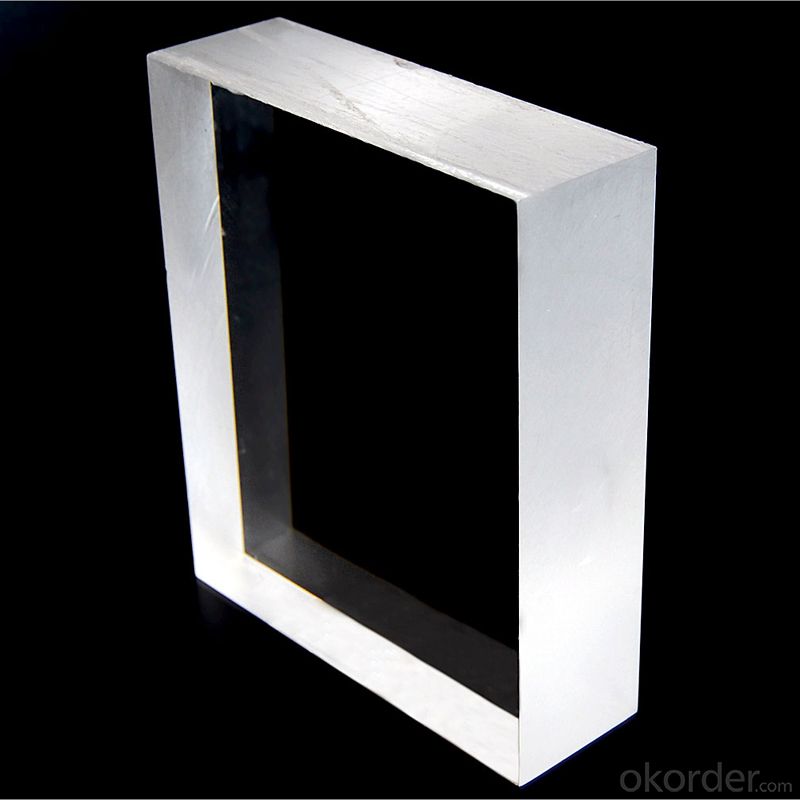

High quality 100% Virgin material clear acrylic sheet

Specifications

1,100% virgin materials;

2,Acrylic Sheet with Hight quality

3,Stable color under outdoor exposure

Feature of acrylic sheet

Perfect transparency and the light transmittance with 93%.

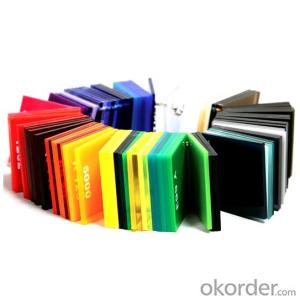

1.Good light transmission. colorful cast plexiglass sheet

2.Good weather resistance. colorful cast plexiglass sheet

3.Can be molded and reprocessed.

4.Widely usage, easy to dyeing and painting.

5.Non-toxicity. colorful cast plexiglass sheet

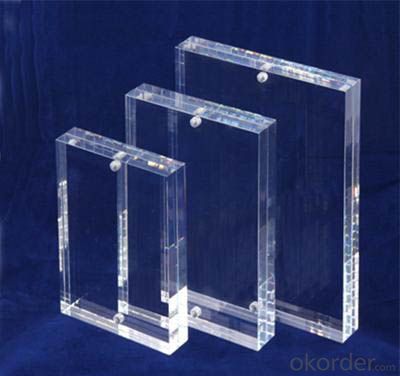

6.High mechanical strength.

7.Light weight. colorful cast plexiglass sheet

8.Good impact strength

9.Good Insulation feature, widely used for different electrical equipment.

10.Good hard coating and scratch resistance

11.Good chemical resistance, superior to most other plastic materials.

12.Easy to clean and maintain.

13.Perfect transparency and the light transmittance with 93%.

Applications of acrylic sheet

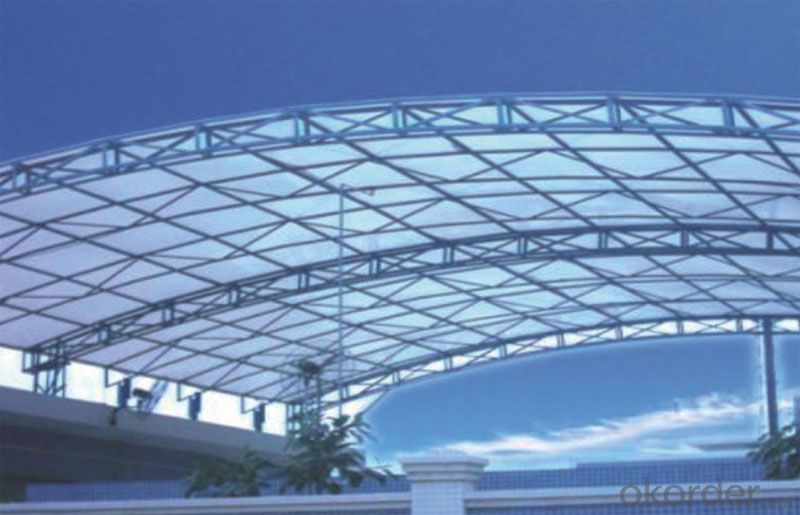

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

Acrylic Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

Application:

Lighting

Indoor windows and doors

Riot windows,shop show window

Show box,Observe window

Awning,carport

Indoor partition

Advertising panel

Sound barrier

- Q: My house is 50 years old and is lacking in insulation in the garage ceiling. Above the garage are bedrooms. Currently there is 3 of fiberglass with an aluminum vapor barrier within a 2x10 joist. I'd like to put R-30 fiberglass in the cavities but the 25' rolls of insulation are unfaced and the faced R-30 rolls are only in 48 batts. 4' sections are easier to put up but that is not a concern of mine.

- Don't use a plastic sheet, use 15# asphalt impregnated felt or a fabric like Tyvek. The vapor barrier must be able to breathe or you run the risk of trapping dampness which will lead to mold.

- Q: Are plastic sheets resistant to chemicals used in swimming pools?

- Yes, plastic sheets are generally resistant to the chemicals used in swimming pools.

- Q: I would appreciate anyones help on this.I have to have a custom high-detailed graphic printed onto a sheet of plastic measuring 25 and 3/4 by 27. I'm assuming I will need a specialist service, but I'm not really too sure where to start, or how much this will cost me. This will be a custom made banner for an arcade machine, if anyone's interested. Can anyone direct me towards services, or even give me an idea of prices? I live in Essex, UK, if anyone can find somewhere local, I would greatly appreciate it!Thanks guys!-Kirsty

- check okorder

- Q: Are there large plastic acitate sheets that can be used for stenciling? larger than 8.5x11?

- OKorder has a vast amount of stencil supplies.

- Q: Are plastic sheets water-resistant?

- Yes, plastic sheets are generally water-resistant due to their impermeable nature, making them suitable for various applications where protection from water or moisture is required.

- Q: Plastic gusset plate how to install the diagram?

- Mounting boom. The installation should meet several requirements: first, and the bearing capacity of the hangers should be straight enough; secondly, we should advance to suspender rust; boom from the keel end shall not exceed 300mm, otherwise should be added if you need additional boom, boom, best lap welding, the main keel to avoid falling;

- Q: Can plastic sheets be used for art and crafts?

- Yes, plastic sheets can definitely be used for art and crafts. They are versatile and can be easily cut, shaped, and molded to create various art pieces, such as sculptures, mobiles, stencils, and even jewelry. Plastic sheets also come in different colors and transparency levels, allowing artists to experiment with different effects and techniques. Additionally, they are durable and lightweight, making them suitable for a wide range of craft projects.

- Q: my car windscreen sticker was full of permanent marker marks done by little kids. i need to lift the marks without spoiling the sticker.

- It can be done quite easily. Try a bit of rubbing alcohol or a paint mixer called thinner. Just wet a piece of cloth in thinner and gently rub off the marker marks. You can even try surgical spirit.

- Q: Are plastic sheets resistant to mold or mildew?

- Yes, plastic sheets are generally resistant to mold or mildew as they do not provide an organic food source for these organisms to grow and thrive.

- Q: Where do u buy sheets of plastic mirror used in magic that are about 5 feet by a little over 2 feet?

- Builder's Square (now out of business) used to carry them. I bought some and attached them to a three-panel screen to use when I practiced tap dancing. Home Depot and Lowe's carried them at one time in their plexiglas sheets department, near the hardware, and in their ceiling panels department, near the lighting. If you have a Sutherlands Lumber near you, you might check with them.

Send your message to us

High Quality 100% Virgin Material Clear Plastic Sheets

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 800 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords