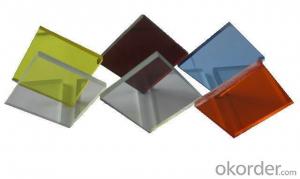

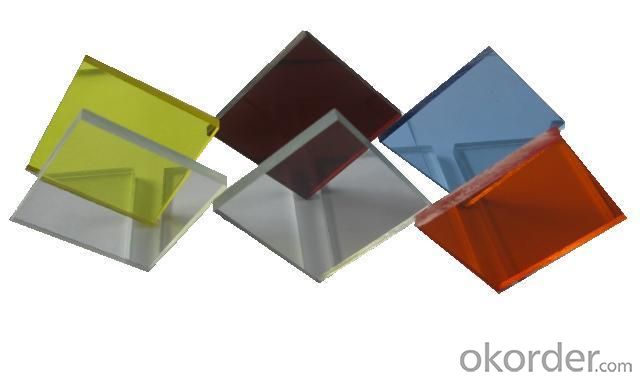

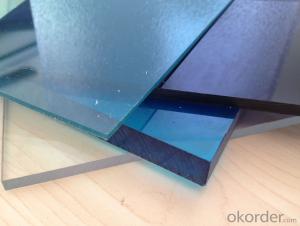

Plastic Sheets - CMAX Cast Acrylic/PMMA Sheet Made of 100% Virgin Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature of colorful cast Acrylic/pmma sheet

Perfect transparency and the light transmittance up to 93%.

Excellent electrical insulation and light weight.

Good plasticity, easy to process and re-shape.

Strong surface hardness and good weather resistant property

Variety of colour, easy to clean

Applications of colorful cast acrylic/pmma sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse, signboard, indicator, display rack.

Vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

colorful cast acrylic/pmma sheet Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | colorful cast plexiglass sheet |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | colorful cast plexiglass sheet |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | colorful cast plexiglass sheet |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

- Q: I am working on case modding my wii and I want to cut a stenciled design out of the plastic on the side. Is there a certain tool that can do this eficiently? im not sure a dremel would work with such an intricuite design (sorry for spelling) so which tool should i use?

- Anthony, I would use a spray glue (sold in the glue section of most stores) and spray the adhesive to the stencil and then apply to the plastic. It's simple to do, just follow directions on the can. Then if you have access to a scrollsaw, you can use a fine blade and cut the design with little trouble, no matter how intricate the design. Of course if you're unable to lay the area onto the flat surface of the scrollsaw, this won't be an option. If you use a dremel, it will be very difficult to follow the lines, plus it will leave a melted area along the cut lines. you could try using a plastic cutting knife, but if the detail is intricate, you won't have very good control. If the plastic is thick, it probably won't cut through the material. You may be able to use a coping saw, if the throat on the saw will clear the side of the plastic so you can cut it. You'd have to drill a starting point for the blade to enter. If the throat is not wide enough on the saw, try removing the blade from the saw and use it without the saw. The blade is very fine and should cut the material, including the intricate areas. That's about they only reliable ideas I can muster. Perhaps someone else has some ideas. good luck

- Q: Are plastic sheets resistant to warping from temperature changes?

- Yes, plastic sheets are generally resistant to warping from temperature changes.

- Q: Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets are generally resistant to cracking from impact.

- Q: I want to build a Darth Vader helmet/mask. Sculpting is no problem, neither is building the vacuum former, but every web link I have found just tells me what kind of plastic to use, not where to buy it.

- Google your own address then Map then Search Nearby and Plastics - Sheet. This should give you places that will sell you many kinds of plastics and will cut down from full sheets (which are 4x8 ft in US) Call them and ask about types and cost. Some specialize. In Dallas Texas, Regal Plastics is one such.

- Q: Can plastic sheets be used for insulation against electromagnetic interference?

- Yes, plastic sheets can be used for insulation against electromagnetic interference.

- Q: A victim of an automobile accident was lying in pain by the side of the road with a thoracic wound which was making a strange sucking noise with each labored inhalation. A passing off-duty paramedic applied a moist plastic sheet to the wound and the sound stopped. Why was the patient in pain? What would eventually have happened to the lung on the injured side if no care had been administered? Why was it important that the plastic sheet be moist?

- You need to do your own homework. Read the chapter on thoracic trauma and figure it out. When you get out into the field no one will be there to spoonfeed you and hold your hand. This is pretty basic stuff.

- Q: We used our Graco Pack and Play for our daughter and now we are expecting another baby and I am again trying to figure out how exactly were supposed to cover the top piece when we change our little one?

- Just keep using a towel. No big deal.

- Q: Are plastic sheets resistant to impact from hail or debris?

- Yes, plastic sheets are generally resistant to impact from hail or debris due to their durable and flexible nature. However, the level of resistance may vary depending on the thickness and quality of the plastic used.

- Q: What are the advantages of LCD TVs, metal and plastic backplanes?

- The metal has a good heat dissipation and low cost. The plastic backboard is beautiful and beautiful, and the safety is better than the metal.

- Q: Can plastic sheets be used for outdoor furniture?

- Yes, plastic sheets can be used for outdoor furniture. Plastic sheets are often used for outdoor furniture due to their durability, weather resistance, and low maintenance requirements. They can withstand exposure to sunlight, rain, and other outdoor elements, making them a suitable choice for outdoor furniture applications.

Send your message to us

Plastic Sheets - CMAX Cast Acrylic/PMMA Sheet Made of 100% Virgin Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords