Cmax Anti-Fire Cast Acrylic Panel - Plastic Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

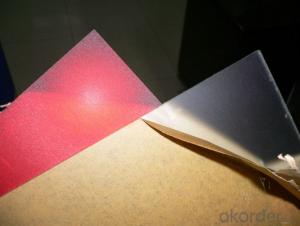

Feature of antifire cast acrylic sheet

Excellent electrical insulation and light weight.

Good plasticity, easy to process and re-shape.

Strong surface hardness and good weather resistant property

Variety of colour, easy to clean

Applications of anti-fire cast acrylic sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse, signboard, indicator, display rack.

Vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

anti-fire cast acrylic sheet Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | colorful cast plexiglass sheet |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | colorful cast plexiglass sheet |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | colorful cast plexiglass sheet |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

- Q: Are plastic sheets resistant to chemicals used in pools?

- Yes, plastic sheets are generally resistant to the chemicals used in pools.

- Q: Can plastic sheets be used for packaging fragile items?

- Yes, plastic sheets can be used for packaging fragile items. They provide a protective barrier and can cushion the items, preventing breakage or damage during transportation.

- Q: She does have Alzheimer's so I really need plastice sheetsIt's hard to work with her on this, she's pretty much lost controland takes off the depends at night while she sleeps and just goes.I do her sheets twice a day, the hospital pads dont cover every inch of her mattress though I try; they move and then and urine seeps thru.Can somebody guide me to where i can buy fitted plastice or old fashioned rubber sheets for a full size bed?

- you can get the kind that go alround the bed at walmart with a zipper on them but your still going to want to put a regular sheet over them to make them more comfortable because in the winter they will be cold and in the summer they will hot and itchy..i got them for my kids both were bed wetters

- Q: lies, in expectation of some kind of Red Chinese or Iranian nuclear event? All of the pollution now experienced in LA comes, after all, from Red China, and any war between they and India, for example would pollute the US for at least two weeks.

- you bet ye, head for your bomb shelters.

- Q: What do you put underneath sand so that it doesnt touch the ground. It is like a sheet.?

- I would get a tall narrow corner cabinet with shelves. That way it takes up the corner and you can put whatever you want on it. Try Pier 1, Ikea, Target, Pottery Barn

- Q: My son got his school pictures recently. Included was a sheet of plastic that had his picture on 3 bookmarks, 2 key chains and 2 wallet cards.My question is how did they do this? I would like to make them myself. I think they used some form of Dye Sublimation printing, but where did they get the perforated plastic sheets?

- merlotony, okorder - this is just one of many companies that specialize in this process, but they were quite helpful in explaining the processes and options when I was starting to look into it. I hope this is helpful to you. Have a good one!

- Q: The plastic plate on the rear axle of the mountain car is loose Is it normal? This is the transparent plate on the map

- The state of the plastic disc by buckles with its elastic fixed drum and drum from the surface and easily said mounted disc before application of force about deformation of disk gap shift in

- Q: the plastic should be plain without any writting at all.

- Hi: The Local hardware store sells Plexiglas Plastic sheet, However you could be use Poster-board or Cardboard for your templates instead of it ,It's cheaper and you use it to cut the stain glass better if you need it thicker than that, Then Layer it with identical pieces or use it to cut a thick piece of cardboard into the shape, Place it where you want it. Mark it with a felt tip marker. than you can start cutting it out where you want it and then use alcohol to clean the Felt tip marking's off ( use a wax marker to number the pieces) then start soldering or whatever to assemble it I hope this helps

- Q: Can plastic sheets be used for machine guarding?

- Yes, plastic sheets can be used for machine guarding. They are commonly used as a protective barrier to prevent operators from coming into direct contact with moving parts or hazardous areas of machinery. Plastic sheets offer visibility, durability, and can be customized to fit specific machine guarding requirements.

- Q: What are the benefits of using plastic chopping board up? What's so bad about it?

- The common market of bamboo and wood chopping board, made of plastic, but the bamboo chopping board should be qualified of natural products, the material is strong and not easy to crack or dregs, dirt is not easy to plug in the gap, relatively clean, clean up is also more convenient. Because bamboo cutting boards are easy to dry, not easy to mildew, no smell, is a good choice. The bamboo chopping board in want of perfection, because the thickness is not enough, and more for the stitching, use not hit, so it is best to cut vegetables or fruit, meat is not suitable for.

Send your message to us

Cmax Anti-Fire Cast Acrylic Panel - Plastic Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords