Neon Packaging Tape - BOPP Tape Resistance to Cold, Heat, and Aging - Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

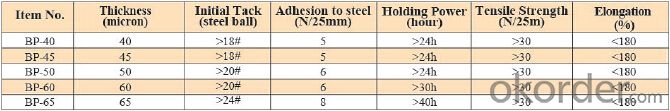

Typical Physical Reports of Bopp Tape

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of BOPP Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Does packaging tape come in different thicknesses for added durability?

- Yes, packaging tape does come in different thicknesses for added durability. Thicker tapes are often preferred for heavier or more secure packaging needs, as they provide increased strength and resistance to tearing or breaking.

- Q: Does packaging tape come in different allergen-free options?

- Yes, packaging tape does come in different allergen-free options. Many manufacturers offer packaging tape that is specifically designed to be hypoallergenic and free from common allergens such as latex, gluten, and other potential irritants. These allergen-free options are particularly beneficial for individuals with sensitive skin or allergies. It is always recommended to carefully read the product labels or descriptions to ensure that the packaging tape meets your specific allergen-free requirements.

- Q: Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is safe to use on stainless steel. Packaging tape is typically made from materials that are not corrosive and will not damage the surface of stainless steel. However, it is always a good idea to test the tape on a small, inconspicuous area of the stainless steel before applying it to the entire surface, especially if the tape will be left on for an extended period of time. Additionally, removing the tape gently and slowly can help prevent any potential damage or residue on the stainless steel.

- Q: How do I seal a package securely with packaging tape?

- To seal a package securely with packaging tape, follow these steps: 1. Start by ensuring that the items inside the package are properly arranged and secured. 2. Cut a piece of packaging tape slightly longer than the width of the box. 3. Place the tape across the center of the box, ensuring it covers the flaps and overlaps on both sides. 4. Firmly press down on the tape to ensure it adheres properly to the surface. 5. Repeat this process with additional strips of tape, placing them parallel to the first strip and overlapping them slightly. 6. For added security, place strips of tape diagonally across the top and bottom flaps, creating an "X" pattern. 7. Apply pressure to the entire length of each strip to ensure a strong bond with the surface. 8. Finally, test the seal by gently tugging at the tape to ensure it holds firmly. By following these steps, you can seal your package securely with packaging tape, minimizing the risk of damage during transit.

- Q: How do I choose the right packaging tape for my needs?

- Choosing the right packaging tape for your needs can be an important decision to ensure your packages are securely sealed during transit. Here are a few factors to consider when selecting the appropriate packaging tape: 1. Strength and durability: Consider the weight and nature of your packages. If you are shipping heavy or bulky items, opt for a tape that offers high tensile strength and can withstand rough handling. Look for tapes made from materials like fiberglass or reinforced with polyester fibers. 2. Adhesive type: Different packaging tapes use various types of adhesives. Acrylic adhesive is common and offers a good balance of performance and affordability. For more challenging surfaces or extreme conditions, consider hot melt adhesive, which provides superior bonding strength. Additionally, water-activated tape, also known as gummed paper tape, is a great option for added security as it forms a permanent bond when moistened. 3. Width and length: Determine the appropriate width and length of tape based on the size of your packages. Thicker tapes are generally more durable, while longer rolls may be more cost-effective for high-volume packaging. 4. Transparency and aesthetics: If you require your packages to have a professional appearance or if you need to see the contents of the package easily, opt for a clear or transparent packaging tape. However, if appearance is not a concern, choosing a colored tape can help with easy identification or branding purposes. 5. Environmental considerations: If you are conscious of your carbon footprint, look for packaging tapes made from eco-friendly materials or those that are recyclable. Some tapes are also water-based, solvent-free, or made from renewable resources, making them a greener choice. 6. Dispenser compatibility: Consider the type of tape dispenser you have or plan to use. Make sure the tape you choose is compatible with your dispenser, as some tapes require specific types of dispensers. 7. Cost: Finally, compare prices and consider your budget. However, keep in mind that sacrificing quality for a lower price may result in inadequate tape performance and potential package damage. By considering these factors, you can make an informed decision and choose the right packaging tape that best suits your needs, ensuring your packages arrive securely and intact.

- Q: How do I apply packaging tape evenly?

- Achieving an even application of packaging tape can be done by following the steps below: 1. Prioritize cleanliness and ensure that the surface to be taped is free from any dust, dirt, or moisture. This will facilitate proper adhesion of the tape. 2. Determine the required length of tape and cut it accordingly. It is advisable to have a slightly longer piece of tape rather than a shorter one. 3. Firmly hold one end of the tape against the surface and apply it at a slight angle, applying gentle pressure. This technique will prevent the formation of air bubbles and ensure a smooth application. 4. As you continue applying the tape, maintain tension and keep it straight. Avoid excessively stretching or pulling the tape, as this can compromise its adhesive properties. 5. Use either your fingers or a tape dispenser to firmly press down on the tape, smoothing it out as you progress. This step guarantees proper and even adhesion to the surface. 6. In the event of encountering wrinkles or bubbles while applying the tape, gently lift it and reapply, smoothing it out as you proceed. 7. Repeat the process until the desired area is covered with the tape, ensuring a slight overlap at the edges for a secure seal. By adhering to these steps, you will be able to achieve an even application of packaging tape, resulting in a tidy and secure seal for your packages.

- Q: Can packaging tape be used for sealing moving boxes?

- Indeed, when it comes to sealing moving boxes, packaging tape proves to be quite useful. Its design is specifically tailored to secure boxes and packages during transit, boasting durability and strength that ensure a tight seal, preventing boxes from opening or items from spilling out. Moreover, its application is quick and effective, making it an easy-to-use option. It is worth noting that packaging tape often possesses resistance against moisture and can withstand diverse weather conditions, which makes it an ideal choice for long-distance moves or storage purposes. In summary, packaging tape is a dependable solution for sealing moving boxes and guaranteeing the safety of your belongings throughout the moving process.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- Cut with automatic cutting machine, first rewinding, using pressure wheel will drive off the bubble, put 3 to 4 days later, with the cutting table cutting, the advantage is that the appearance of adhesive tape, but the disadvantage is that the production cycle is longer.I hope this will be accepted

- Q: What are the considerations for using packaging tape on glossy surfaces?

- When using packaging tape on glossy surfaces, there are a few important considerations to keep in mind. Firstly, the adhesion of the tape may be affected by the smoothness and slickness of the glossy surface. The glossy finish can create a barrier that makes it challenging for the tape to stick securely. Therefore, it is crucial to ensure that the surface is clean and free from any dirt, oils, or residue that could hinder the tape's adhesion. Additionally, the type of packaging tape used is important. Opting for a tape specifically designed for glossy surfaces, such as high tack or acrylic adhesive tapes, can provide better adhesion and longevity. These tapes are formulated to adhere well to smooth surfaces and offer stronger bonds compared to regular packaging tape. It is also advisable to test the tape on a small, inconspicuous area of the glossy surface before applying it extensively. This will allow you to gauge the tape's adhesion and ensure that it does not leave any residue or damage the glossy finish when removed. Furthermore, the temperature and environmental conditions should be considered. Extreme heat or cold can impact the performance of the tape on glossy surfaces. For instance, high temperatures can cause the adhesive to soften, leading to tape failure, while cold temperatures may make the tape more brittle and prone to peeling. Lastly, it is essential to handle the glossy surface with care to avoid fingerprints, smudges, or scratches that may diminish its appearance. Wearing gloves or using protective films can help prevent such issues. By considering these factors, you can increase the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the aesthetic appeal of the glossy finish.

Send your message to us

Neon Packaging Tape - BOPP Tape Resistance to Cold, Heat, and Aging - Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords