Packaging Tape Grey Cloth Tape Polyethy Cloth Hot Melt Adhesive 27 Mesh

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

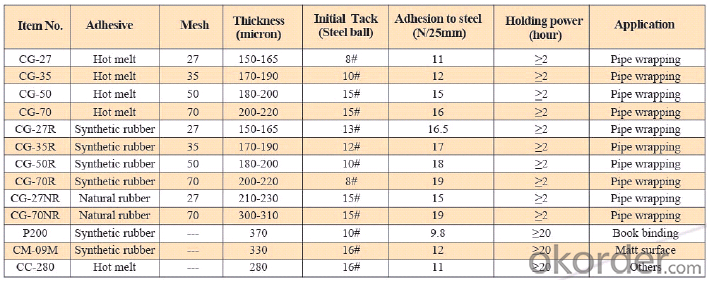

Typical Physical Reports of Cloth Tape

Packaging Detail

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: How do I store packaging tape?

- For optimal storage of packaging tape, it is recommended to place it in a cool and dry location, avoiding direct exposure to sunlight. This will maintain the tape's adhesive qualities and prevent it from becoming fragile or losing its stickiness. An ideal option for this purpose would be a plastic storage bin or a cool, dry drawer. Additionally, it is advisable to either keep the tape in its original packaging or employ a tape dispenser to safeguard it against dust and other impurities. By adhering to these storage instructions, you can guarantee that your packaging tape remains in excellent condition and readily available for whenever it is required.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can definitely be used for other purposes besides packaging. Due to its strong adhesive properties and durability, it can be used for a variety of tasks. For example, it can be used for household repairs such as fixing a broken book spine or securing loose cables. Additionally, it can be used for crafting projects like creating temporary or permanent decorations, making durable envelopes, or even in DIY projects like creating makeshift labels or organizing items. Furthermore, packaging tape can also be used for temporary fixes, such as sealing small leaks or cracks in pipes or containers until a permanent solution is found. The versatility of packaging tape makes it a handy tool to have around the house or office for various purposes beyond just packaging.

- Q: Is packaging tape transparent?

- Yes, packaging tape is usually transparent.

- Q: Does packaging tape come with a dispenser?

- Yes, packaging tape often comes with a dispenser for easy and convenient use.

- Q: How do I prevent packaging tape from losing its color over time?

- To prevent packaging tape from losing its color over time, here are a few strategies you can try: 1. Store the tape properly: Exposure to sunlight and extreme temperatures can cause the color to fade quickly. Keep your packaging tape in a cool, dark, and dry place to maintain its color for longer. 2. Avoid direct contact with moisture: Moisture can be detrimental to the adhesive and color of the tape. Make sure to store it away from areas prone to water leaks or high humidity levels. 3. Choose high-quality tape: Some packaging tapes are made with better quality materials that are less likely to lose their color. Look for tapes that are specifically designed for long-lasting color retention. 4. Limit exposure to air: Oxygen can also contribute to the degradation of color. After use, make sure to seal the packaging tape tightly to minimize its exposure to air. 5. Handle with care during use: Rough handling can cause the color to rub off or fade faster. Be gentle when applying and removing the tape to maintain its original color. 6. Consider using protective coatings: If the packaging tape is essential for branding purposes or aesthetic appeal, you can explore using protective coatings or laminates. These coatings can provide an additional layer of protection to prevent color loss. By implementing these measures, you can extend the lifespan and color vibrancy of your packaging tape, ensuring it remains visually appealing for a longer period.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. Packaging tape is specifically designed to securely seal packages, providing protection against tampering, moisture, and damage during transit. It is strong, durable, and often features a strong adhesive backing that creates a long-lasting seal. When applied properly, packaging tape can effectively secure packages containing high-value contents, ensuring their safe delivery. However, it is important to consider additional security measures, such as using tamper-evident tape or adding extra layers of protection, depending on the value and fragility of the contents.

- Q: How do I prevent packaging tape from yellowing over time?

- To prevent packaging tape from yellowing over time, it is essential to store it in a cool, dry, and dark place. Exposure to sunlight and humidity can accelerate the yellowing process. Additionally, using high-quality packaging tape made from materials resistant to discoloration can help maintain its original appearance for a longer period.

- Q: Can packaging tape be used for sealing camping or outdoor gear?

- Yes, packaging tape can be used for sealing camping or outdoor gear. It is strong and durable, providing a temporary seal for items such as tents, sleeping bags, and backpacks. However, for longer-term or more permanent seals, it is recommended to use specialized outdoor repair tapes or adhesives designed for outdoor gear.

- Q: Can packaging tape be used for sealing packages for international shipping?

- Yes, packaging tape can be used for sealing packages for international shipping. It provides a reliable and secure seal that can withstand the rigors of transportation, ensuring the contents of the package remain intact during their journey.

- Q: The production of transparent tape material is what to do

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

Send your message to us

Packaging Tape Grey Cloth Tape Polyethy Cloth Hot Melt Adhesive 27 Mesh

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords