Cheap Custom Packaging Tape - Cloth Tape Polyethylene Cloth Hot Melt Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

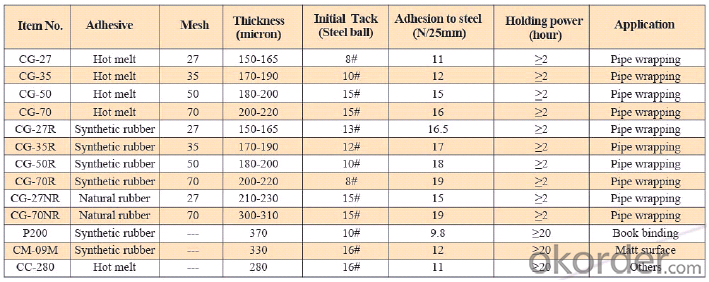

Typical Physical Reports of Cloth Tape:

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: How to adjust the tightness of belt pulley in belt sealing machine?

- Full automatic sealing machine, pneumatic sealing machine, folding lid sealing machine, corner sealing machine,

- Q: Can packaging tape be used for sealing cloth or fabric items?

- Packaging tape has the capability of sealing cloth or fabric items. Its design ensures strength and adhesive properties, making it efficient for securing and sealing different materials, such as cloth and fabric. When it comes to packages containing cloth or fabric items, packaging tape becomes particularly handy as it ensures a secure closure that prevents any potential damage or loss during transportation or storage. Furthermore, the transparency of packaging tape allows for effortless identification of the contents while maintaining the overall appearance of the cloth or fabric item intact.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. It provides a secure and effective way to seal the packaging, ensuring that the contents remain protected during transportation or storage.

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Yes, packaging tape can be used for sealing plastic or poly bags. Packaging tape is specifically designed to provide a strong and secure seal on various surfaces, including plastic and poly bags. It has an adhesive backing that adheres well to the plastic material, ensuring that the bag remains tightly sealed. However, it is important to note that there are different types of packaging tape available, so it is recommended to choose a tape specifically designed for sealing plastic or poly bags to ensure optimal performance and long-lasting seal.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can be used for other purposes besides packaging. It can be used for sealing envelopes, securing loose items, repairing torn paper or books, creating temporary labels, organizing cables, and many other miscellaneous tasks.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, ensure that the tape roll is placed on a dispenser or a stationary surface with the sticky side facing down. Additionally, avoid pulling the tape too quickly or at an angle, as this can cause it to twist and tangle. Taking these precautions will help maintain the tape's smooth flow and prevent any frustrating tangles.

- Q: Can packaging tape be used for sealing wooden furniture?

- Yes, packaging tape can be used for sealing wooden furniture. While it may not be the most conventional or aesthetically pleasing option, packaging tape can effectively seal gaps or cracks in wooden furniture, preventing dust, moisture, or insects from entering. However, it is important to note that packaging tape is not a long-term solution, as it may not provide the same level of durability or stability as other sealing methods specifically designed for wooden furniture, such as wood glue or epoxy. Therefore, it is recommended to use packaging tape as a temporary fix until a more appropriate sealing method can be applied.

- Q: Can packaging tape be used for sealing documents or important papers?

- Packaging tape is not typically recommended for sealing documents or important papers. While it may provide a temporary solution in certain situations, it is not designed for this specific purpose. Packaging tape is primarily used for securing packages and boxes during transportation, and its adhesive properties may not be suitable for delicate papers or documents that require long-term protection. Additionally, using packaging tape on important papers may leave behind residue or damage the paper itself. It is advisable to use specialized document sealing products, such as document envelopes or archival folders, which are designed to provide proper protection and preservation for important papers.

- Q: Does packaging tape come in different adhesion levels for various surfaces?

- Packaging tape is available in different adhesion levels to suit various surfaces. The market offers a range of packaging tapes, each tailored to adhere to specific surfaces. For instance, there are packaging tapes with low adhesion levels, perfect for delicate surfaces like paper or cardboard. These tapes provide a strong bond without causing any damage when removed. Conversely, high adhesion packaging tapes are specially formulated to stick to rough or uneven surfaces such as plastic or metal. These tapes have a more powerful adhesive to ensure a secure hold, even in challenging environments. Moreover, there are packaging tapes with medium adhesion levels that offer versatility and can be used on a variety of surfaces. The availability of different adhesion levels allows users to select the most suitable packaging tape for the specific surface they need to adhere to, ensuring optimal performance and reliability.

- Q: Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. It is designed to provide strong adhesion and durability, making it suitable for securing and sealing heavy or bulky items during transportation or storage.

Send your message to us

Cheap Custom Packaging Tape - Cloth Tape Polyethylene Cloth Hot Melt Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords