Scotch Packaging Tape Heavy Duty for Pipe Wrapping Black Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

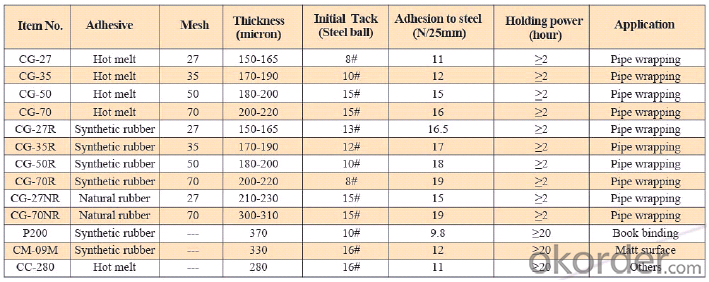

Typical Physical Reports of Cloth Tape:

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing plastic toolboxes?

- Yes, packaging tape can be used for sealing plastic toolboxes. The strong adhesive on packaging tape can effectively seal the edges and seams of plastic toolboxes, providing a secure closure. However, it is important to consider the weight and durability of the items being stored in the toolbox, as packaging tape may not be as robust as specialized toolbox sealants or gaskets.

- Q: Selection of tapes

- So how do you choose the tape? In fact, the adhesive tape in the use of good and bad there are two criteria, one is the initial viscosity, one is to maintain the force, the two are inversely proportional. Under normal circumstances, adhesive force less than 10 adhesive tape is glue coated, teach less, usually only about 20 microns, such as stationery, tape, ordinary promotion belt used adhesive tape. The initial adhesive force of the normal sealing tape is between 15-20. The thickness of the adhesive tape is 22-28 microns. Is the standard thickness. But the tape on the market are mostly mixed with impurities, so the increase of the thickness of shielding impurities, the glue is also mixed with the toner, so transparent tape appeared egg yellow, light green, this tape is generally inferior.

- Q: Are there any eco-friendly options for packaging tape?

- Yes, there are eco-friendly options for packaging tape available. Some alternatives to traditional plastic packaging tape include paper tape, which is made from renewable resources and can be recycled or composted. Another option is water-activated tape, which is also made from paper and uses a natural adhesive activated by water. These eco-friendly packaging tape options help reduce plastic waste and are more sustainable choices for packaging needs.

- Q: What are the considerations for using packaging tape on temperature-sensitive items?

- When using packaging tape on temperature-sensitive items, it is crucial to consider the adhesive's temperature resistance. Opting for tape specifically designed for extreme temperatures will prevent the tape from melting or losing its adhesive properties. Additionally, choosing a tape that adheres well to a variety of surfaces is important to ensure the package remains intact, even in fluctuating temperatures. Properly securing the package with sufficient layers of tape can also provide insulation and protect the item from temperature variations.

- Q: Can packaging tape be used for sealing plastic shoeboxes?

- Yes, packaging tape can be used for sealing plastic shoeboxes. It provides a strong and secure seal, keeping the contents of the shoeboxes safe and protected.

- Q: Is packaging tape resistant to punctures or tears?

- Yes, packaging tape is generally resistant to punctures or tears. It is designed to be strong and durable, specifically for securing and sealing packages. Packaging tape is made from materials such as polypropylene or polyester, which have high tensile strength and offer excellent resistance to punctures or tears. Additionally, packaging tape often has adhesive properties that further enhance its ability to withstand punctures or tears. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Can packaging tape be used for sealing packages with sharp edges or corners?

- Packaging tape is capable of sealing packages that have sharp edges or corners. Its purpose is to securely seal boxes and packages of different shapes and sizes due to its strength and durability. In the shipping and packaging industries, it is widely used to guarantee the preservation of package contents while in transit. The adhesive on the tape is generally powerful enough to stick to sharp edges and corners, creating a dependable seal. Nevertheless, it is crucial to apply the tape correctly and securely to avoid any potential harm or interference during shipping.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is typically designed to be easily removed without causing any harm to surfaces. However, the ease of removal can vary depending on several factors, including the type and quality of the tape, the surface it is applied to, and how long it has been in place. Most packaging tapes are created to stick firmly to surfaces during transportation or storage, ensuring that the package remains sealed and secure. Nevertheless, they are also formulated to be peeled off easily when necessary, without leaving any residue or causing damage. In most situations, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is generally developed to strike a good balance between sticking power and ease of removal. This allows for effortless removal without the need for excessive force or any sticky residue. However, there may be instances where the tape might be more challenging to remove, particularly if it has been in place for a long time or exposed to extreme temperatures. In such cases, using heat, such as a hairdryer, to soften the adhesive can be helpful, making it easier to peel off. It is important to note that the ease of tape removal can also be influenced by the surface it is applied to. Smooth and non-porous surfaces like glass or metal are generally easier to clean without causing any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to prevent any potential damage. In conclusion, while packaging tape is generally designed to be easily removed without causing damage, it is essential to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

- Q: How do I prevent packaging tape from becoming too loose?

- Here are some helpful suggestions for preventing packaging tape from becoming loose: 1. Opt for high-quality packaging tape: Invest in packaging tape that boasts a strong adhesive. Inferior quality tapes tend to lose their stickiness quickly, resulting in loose packaging. 2. Ensure cleanliness and dryness of surfaces: Prior to applying the tape, make sure that the surfaces are clean and dry. Dust, moisture, or oil can weaken the adhesive and cause the tape to loosen. 3. Apply firm pressure: When sealing a package, exert firm pressure while affixing the tape onto the surface. Be sure to run your hand or a flat object along the length of the tape to ensure proper adhesion. 4. Utilize overlapping tape: Instead of using only a single strip of tape, overlap it by a few inches. This overlapping technique provides added strength and diminishes the likelihood of the tape becoming loose. 5. Avoid extreme temperature fluctuations: Extreme temperature changes can adversely affect the adhesive properties of packaging tape. Refrain from storing packages in areas with high humidity or extreme temperature variations, as this can cause the tape to loosen. 6. Strengthen with extra tape: If you are sealing a heavy or bulky package, contemplate reinforcing it with additional tape. Apply extra strips of tape across the sides or diagonally to provide supplementary support and minimize the risk of the tape coming loose. 7. Properly store packages: When storing packages, ensure they are stacked correctly and not subjected to excessive pressure or weight. Inadequate storage conditions can cause the tape to loosen over time. By adhering to these recommendations, you can effectively prevent packaging tape from becoming too loose, thereby guaranteeing that your packages remain securely sealed during transit or storage.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- The bubble is on the tape slitting machine when cutting the air into the tape to improve only by changing the type or sub machine will have a bubble for 1 months or longer, the bubbles will automatically eliminate, the premise is to increase the cutting of the tape tension, if loose, put a few day and bubble;

Send your message to us

Scotch Packaging Tape Heavy Duty for Pipe Wrapping Black Cloth Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches