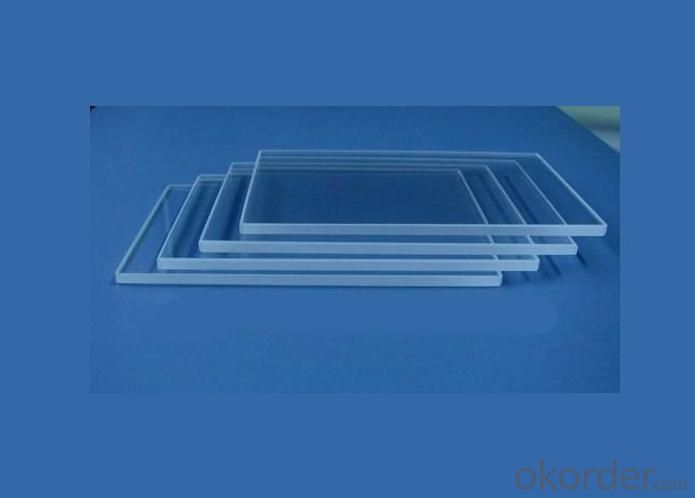

Clear Glass Ceramic

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Square Meters m²

- Supply Capability:

- 10000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main colors: black, clear,white, dark red

Thickness: 3.8mm 4mm 4.5mm 5mm 6mm

max size 420*1500mm

Specifications of Clear Glass Ceramic

Transparent glass ceramic is made of uniformed crystallization and Lithia. The crystal nucleus can prevent expansion. It also provides chemical stability, resist impact damage, and it is transparent. Electronic glass-ceramic is used as faceplate or panel of various electronic furnaces.

Main colors: black, clear,white, dark red

Thickness: 3.8mm 4mm 4.5mm 5mm 6mm

max size 420*1500mm

temperature resistance >1000 °C

heat impacting >700 °C

Description of Clear Glass Ceramic

White glass ceramic low coefficient of heat expansion

Excellent shock resistance

Size can be customized

Do print

Quality Assurance of Clear Glass Ceramic

1. Density---approx. 2.56 g / cm3

2. Modulus of Elasticity--- approx. 93 x 103 Mpa 3, Bending Strength--- approx.

3. 6 MPa The bending strength testing is to be accomplished according to DIN EN 1288 part 5 (R45).

4. Thermal Characteristics Coefficient of Mean Linear Expansion---α(20 - 700oC) (0 ± 0.5) x 10-7 /K

5. Resistance to Temperature Differences (RTD) Resistance of the panel to temperature differences between heated zone and cold panel edge (room temperature). No cracking due to thermal stress at Tes, max1<=700 degree C

6. Thermal Shock Resistance Resistance of the panel to thermal shock when the hot panel (780 degree C) is quenched with cold water (20oC temperature). No cracking due to thermal stress at Tes, max<=700 degree C

7. Chemical Characteristics of Base Material Acid Resistance--- DIN 12116: at least class S3 Alkaline Resistance---based on ISO 695: at least class A2

8. Screen printing: complies with RoHS standards, normal ink available

9. Impact resistance: A steel ball (diameter 60mm, weight 188g) freefall from180mm height, striking the panel

10 times. No scratching or cracking.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: What are the chemicals in glass?

- (some of these ingredients are repeated, and the content of the active ingredients should be carefully calculated when firing the glass) In addition, there are some trace elements, such as metal oxides, used for colored glass, shielding electromagnetic, optical glass and so on. Some other types of special glass materials account for a large proportion of raw materials, and may even contain quartz sand.

- Q: Is glass steel pipe used for re examination?

- The main construction phase: a layer structure (scheme, technical disclosure basis has been included, steel raw materials, testing report report, flash butt welding, electroslag welding sampling, sample, steel concealed, reinforcing steel bar, batch inspection, template technology review).

- Q: What's the price of 0.85mm thick plexiglass, please?

- Joint venture material is better, about 600 or so, I personally think that the choice of joint venture board is still ideal.

- Q: How to identify and select high quality insulating glass?

- Hollow glass is composed of two or more pieces of glass, the glass by the internal filling the hollow aluminum isolation desiccant, and the hollow part filled with dry air or inert gas, and sealed with butyl rubber, polysulfide rubber or plastic structure, form dry space glass.

- Q: What kind of glass material is used in the aquarium?

- Float glassClear float glass is a paste by the control gate into the tin groove, due to gravity and surface tension of molten tin floating on the surface after re entering the glass Lengcao Xu, smooth, corrugated and made to disappear. Dark green, smooth surface, no ripple, good perspective, with a certain toughness.

- Q: What are the characteristics of the gas flow in the flame space of a glass furnace?

- Melting: mix into the glass melting furnace, at 1700 degrees of melting into glass liquid; 5, molding: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass; 6, annealing: the glass forming into the annealing furnace annealing, stress balance, prevent from breaking crack. Finally, inspection and packing.

- Q: How do you pack something into (Qian Jin) plexiglass?

- The organic glass is divided into two layers to seal the flat object and then polish it.

- Q: FRP process piping manufacturing process?

- Glass tube wall structure from inside to outside are: glass fiber reinforced plastic lining layer, glass fiber reinforced plastic sub lining layer, glass fiber reinforced plastic winding layer, glass fiber reinforced plastic external protection layer.

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2011 |

| Annual Output Value | |

| Main Markets | 8.33% North America 8.33% South America 8.33% Eastern Europe 8.33% Southeast Asia 8.33% Africa 8.33% Oceania 8.33% Mid East 8.33% Eastern Asia 8.33% Western Europe 8.33% Central America 8.33% Northern Europe 8.33% Southern Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | guangzhou |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Clear Glass Ceramic

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Square Meters m²

- Supply Capability:

- 10000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords