Ceramic Glaze Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 20000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

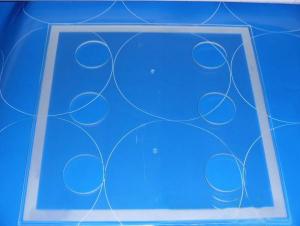

Silkscreen Printing Glass is a kind of glass on which inorganic enamel is printed by silkscreen printing machines. After being printed on, it will be dried and heated under high temperature to make the enamel adhere to the glass lastingly.

Features of Ceramic Glaze Glass:

1. Special quality

2. Clear and vivid custom-made pictures and patterns

3. Alkali-resistant and acid-resistant

4. Its color will not fade after it is heated under high temperature.

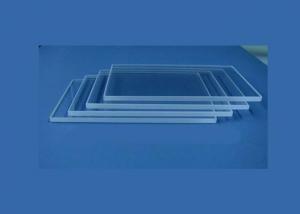

Specifications of Ceramic Glaze Glass:

Thickness: 4-19mm

Size: 2440*4500mm

300*300mm

customized size

Applications of Ceramic Glaze Glass:

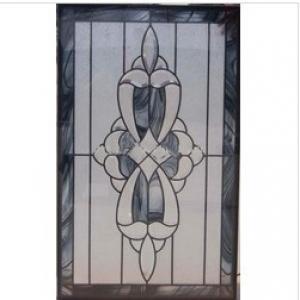

Silkscreen Printing Glass with no pollution, great magnificence, high transmittance and high fidelity can be widely used in the fields of interior wall, exterior wall, furniture, cupboard,showcase, screen, household appliance and solar energy.

- Q: What is the raw material for making glass?

- The main raw material is quartz sand. Because of the high melting point of quartz sand, it is necessary to add a flux of sodium carbonate (that is, our usual surface base) to molten glass when melting,

- Q: How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q: What are the cutting and cutting of acrylic and aluminum-plastic plates?

- The splint knife acrylic, aluminum plate can also draw three splint that can also use a hacksaw, to fine tooth saw blade.

- Q: What material can not be sprayed on the glass?

- 1.. First spray the glass and then stick it on the outside with a transparent adhesive tape..2. uses the special printing ink for the glass product, 3. uses the glass glue to adjust the soluble pigment and the dye toner. 4. go to the print shop and do the writing, then glue it on. I hope my answer will be of some help to you

- Q: What kind of glass is smoked glass?

- * basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: What is the raw material of glass glue?

- Mainly divided into two categories: neutral acid silicone rubber polyurethane adhesive can be indoor and outdoor weathering 107 RTV silicone rubber and calcium carbonate, silica, additives, mixing, vacuum glass glue chemical formula: 107RTV+SiO2+CaCO3= glass glue according to the technical requirements of the chemical equipment selection will differ.

- Q: Medium temperature glass flake clay products

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale, which is made of c- glass, has excellent chemical durability.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are two kinds of molding process, high temperature molding (SMC molding) and room temperature molding (hand paste or vacuum assisted molding). SMC molded, there is no problem of glass fiber, hand paste or vacuum assisted molding. If it takes a long time, you will see the bare phenomenon of glass fiber. You can look at the back of his shell, and if you see the surface is not smooth, it should be hand shaped, usually if the car's output is very large, with SMC molding more. My humble opinion. I hope I can help you.

- Q: Samsung LCD panel information

- This screen is indeed the original Samsung screen, Samsung Electronics, Tianjin Corporation assembly production.TSEC is the sign of Tianjin's samsung. So he wrote the MADE IN CHINA (TSEC) behind him

- Q: What's the difference between crystal and ordinary glass?

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1996 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 101 - 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Glaze Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 20000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches