Cleaning In Place Machine for Stainless Tanks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Processing: Washer, cutting-rolling -welding -polishing -assembing -testing -warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: CIP cleaning machine, KB-009

Voltage: 380V, 50HZ

Certification: B&V, CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

Images:

Specifications

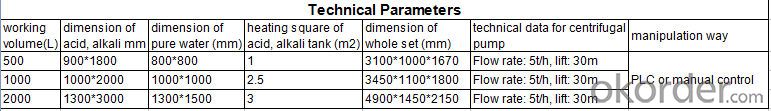

1.acid storage tank 2.alkali storage tank 3.fresh water storage tank

4.centrifugal pump 5.pipes and valves

| CIP Cleaner | |

| Company introducation | We Kuangbo is a production enterprise of pharmaceutical, dairy, food and beer-making equipment, alongside biological engineering, chemical containers, and bespoke products. Our products are widely used in beer production, pharmaceuticals, beverage industries, biotechnology and other fields. |

| Usage | it is used for cleaning pipes and tanks after the production process |

| Material | 1.SUS304, 316L |

| 2.as to the thickness, we can make it according to your requirement. | |

| Configuration | 1.acid storage tank |

| 2.alkali storage tank | |

| 3.fresh water storage tank | |

| 4.centrifugal pump | |

| 5.pipes and valves | |

| Our advantage | 1.we can supply various kinds of volume, minimum 50L, maximun 2,000L. |

| 3.interior surface is 3A finish and exterior is 2B finish | |

| 4.competitive price and also higher quality tank. | |

| Minimum order | one unit |

| Payment term | T/T or L/C |

| Package | export standard package |

| Market | at home and abroard |

- Q: I think it implies a shady business that is only around for a short time. This phrase isn't used so much anymore, but I was wondering what it was all about.

- A business run out of the basement (boiler room)...kind of shady. Often involves calling thousands of people on the phone and selling something fishy, like stock in a company, where the company isn't real or isn't successful.

- Q: any theories, flame ignites then suddenly shuts off tripping the fuse box on potterton lynx 2 boiler?

- I am assuming you are UK. There could be any number of things causing this and when you say it trips the fuse box I am assuming you mean the earth leakage trip so everything goes off. Have you checked around the boiler its self for water leaks or possibly cable damage. You can remove the outer white casing as that is not a safety issue but turn off the supply to the boiler first. Look around the boiler for any sign of water where there shouldnt be any as it may be dripping onto electrical components or check the wiring harness as it may be touching the boiler somewhere and causing an earth fault. Cannot really help more than that as I cannot see the boiler.

- Q: What does the boiler tonnage mean?

- For example, the boiler tonnage is 130 tons, then the boiler up to an hour to create 130 tons of saturated steam.

- Q: give me design details of a coal fired water tube boiler.&also i want to know about the thermal design details

- That depends if you are talking about a drum type boiler or a once through. A drum type boiler will have water in the boiler tubes going to a drum. The water in the drum will boil and create steam that comes out of the top of the drum that goes through some sort of superheater tubes and on to the turbine. These boilers are fired for pressure because the fire maintains the pressure in the drum. In a one through type boiler there is no boiler drum. The water is pumped into hundreds of boiler tubes and turns from water to steam while traveling through the tubes on the way to the turbine. These types of boilers are fired for temperature because the pressure is maintained by the pumps pumping water into the boiler and temperature is maintained by the amount of fire. The once through boilers are usually higher pressure and higher flow boilers.

- Q: A steam ton of boiler gas consumption of 80m ? / hour, how is this calculated?

- 1 ton of water into 1 ton of steam, that is, water rose from 20 degrees to 100 degrees, and then gas words.

- Q: Organic heat carrier boiler, rated thermal power 1.4MW converted tons is how much?

- For special equipment operators, they can be specified in the qualification items of the special equipment operator's certificate, expressed as Class III (Advanced), Level II (Intermediate), Level I (Primary).

- Q: I have an oil fired boiler. I want to run Waste vegetable oil in it. What do I need to do to do these?

- You need to change the vegetable oil into bio-diesel.

- Q: my hot water boiler is losing pressure my boiler is a valiant?

- this could be due to a leak? if your expansion vessel as lost pressure your pressure gauge will rise up to 3bar of pressure when heating is on then go down to 0bar when it turns of you don't always have to change the vessel it can be re pressurised using a foot pump with a gauge on and pumping back up to 1.5 bar experienced plumber

- Q: How does the condensing gas boiler work?

- In the conventional boiler, the exhaust gas temperature is generally 160 to 250C or higher, so that the water (such as natural gas: CH4 + 2O2? CO2 + 2H2O) generated in the combustion of the fuel is in a state of superheat in the flue gas.

- Q: How did the explosion of the boiler cause

- Combustible gas or dust and air mixture in a short period of time a chemical reaction, resulting in high temperature, high pressure gas and shock waves, more than the surrounding buildings, containers, piping carrying capacity to cause damage, resulting in personal and equipment accidents, said

Send your message to us

Cleaning In Place Machine for Stainless Tanks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords