Circular Tube Belt Conveyor,Round Pipe Belt Conveyor,Continuous Transmission Equipment,Belt Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

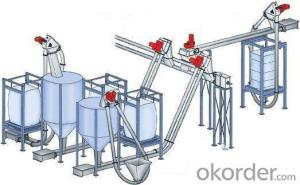

As the development of the modern industrial requirements, environmental protection has gradually became a significant question nowadays. It also rises wide attention all over the world. It is environment pollution which contains powder and waste caused by bulk materials transmission system in the process that has attracted more attentions in mechanism design ministry、fabricated ministry、operational ministry and administrative management in the world. In order to reduce pollution and meet the requirements of environmental protection and pollution-free in the course of transmission, round pipe belt conveyor is invented.

Serving as a kind of continuous transmission equipment about environmental protection, round pipe belt conveyor has attracted all industrial attentions. It is widely used in port、metallurgy、construction materials、electricity、paper making and petrochemical industry to convey coal、cleaned coal、coke、blending materials、sinter、mineral powder、petroleum coke、limestone、aggregate、carbide slag、humidification ash、chemical fertilizer、salt、waste paper、ardealite、pyrite cinder and other bulk materials. As the same as the working principle of normal belt conveyor, the round pipe belt conveyor move the material and belt by friction drive. Most assembly units are as the same as the assembly units of normal conveyor. It the pipe that is used to convey.

Perform feature

It adopts sealed conveying, which aims to prevent the environment from polluting

When it is transported, the branch for bearing the weight and the branch for returning stroke are sealed to convey the materials, which can prevent the materials from splashing, spilling and falling down. Not only can it prevent the along way environment from polluting by the falling materials, but also it can avoid materials. In the meanwhile, it can prevent the materials from wind blows, insolation, raining and other environment factors., which can ensure the quality of the materials. It is significant to convey the powdery materials, viscous materials or the chemical materials that it emits noxious gas.(Such as slaked lime, cement, sewage sludge, coal powder, dry ash, chemical fertilizer and etc.)

The materials are conveyed in the way of a large inclination angle, which can shorten the horizontal length of the conveyor.

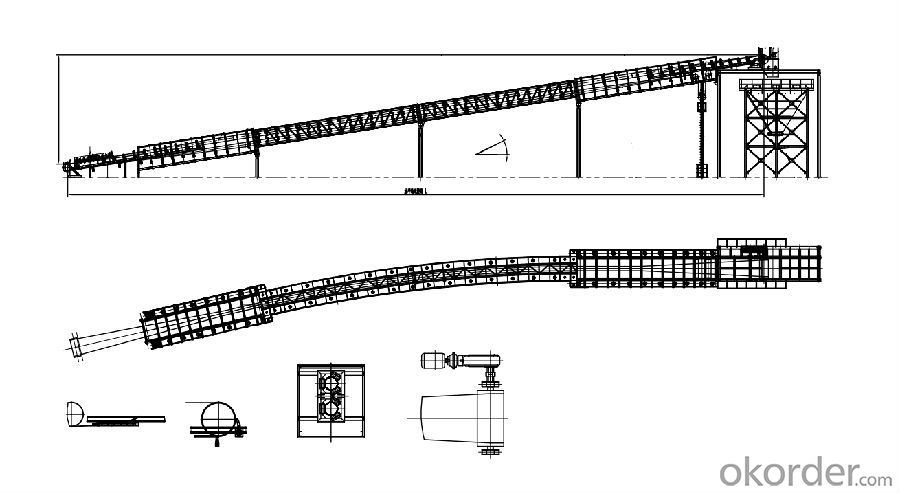

Shaping in a round tube, the belt of conveyor covers the material. It can increase the contact area and pressure between the belt of conveyor and materials. Thus, it increases the equivalent of friction. By means of increase the inclination-angle of transported materials, it can shorten the horizontal length of the materials. The max. recommended inclination-angle of round pipe belt conveyor is 30°. If it adopts the belt which has special surface, the inclination angle of the round pipe belt conveyor can reach 45°~45°. The inclination angle of the round pipe belt conveyor is 10°bigger than the common belt conveyor, generally speaking.

Sketch

Small radius of turning circle

Comparing with common belt conveyor, the radius of turning circle of round pipe belt conveyor is smaller. The mini. radius of turning circle is 8m. Thus, this kind of round pipe belt conveyor can be laid out in a curve environment. The round pipe belt conveyor can be set over the river, highway, railway. Also, it can bypass the construction, which can leave out the middle transfer post. It can simplified the conveyor line and save the investment of capital construction.

It has a compact structure, which cover small space.

The round pipe belt conveyor has a compact structure. On the condition of the same transportation value, the cross sectional area of the round pipe belt conveyor is 1/3 of common belt conveyor with the covering and 1/2 of common belt conveyor without covering. It follows that the covering space of the round pipe belt conveyor is small.

Bidirectional transport

Because , the upper branch and bottom branch of the round pipe belt conveyor is made of round pipe, the bottom branch also can transport the materials in a reversing direction.

Wide range of transported materials

The various materials are conveyed includes bits of wood, chemical fertilizer, sand, gravel, cement, mineral waste residue, cinder, coal, coke, ash, limestone, brown coal, ore, sandstone, gypsum, lime, concrete, rubber, clay, resin, crude salt, crown sugar, grain and etc. The round pipe belt conveyor has following advantages, such as high reliability, low-energy consumption, small amount of maintenance, low cost, low noise and etc.

It can convoy the bulk material in a sealing condition.

The routine can be in curve in space.

It can not pass the line deflection.

It can enhance the transport inclination angle.

It can convey the material in a bidirectional way.

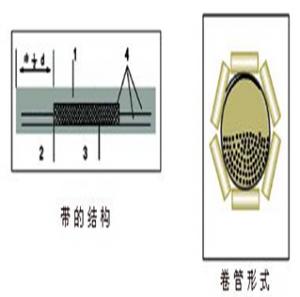

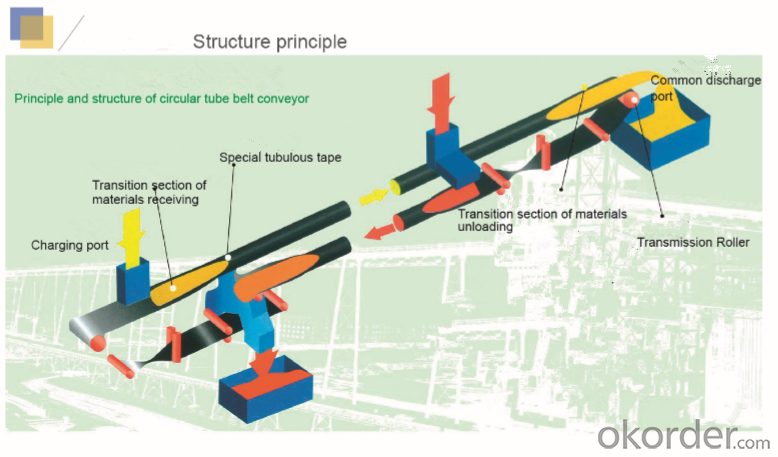

When the conveyor belt has received the materials from the transition section on its tail,the conveyor belt will be rolled up in the circular tube shape gradually,then,the circular tube tape will be applied to transport the materials in the sealed way,then,the conveyor belt will be unfolded gradually when the materials are transported to the head transition section until the/materials are discharged.(As the figure shows)

Technical specification

The relation between the width and delivery value

Speed of width (m/s) | 7.1 | 150.6 | 338.8 | 602.2 | 941.0 | 1355.0 | 1844.4 | 2409.0 | 3048.9 | 3764.0 | 4721.6 | 5420.2 | 5975.8 | 7377.5 | 9635.9 | 10878.0 |

6.3 | 133.6 | 300.6 | 534.4 | 835.0 | 1202.4 | 1636.6 | 2137.5 | 2705.3 | 3339.9 | 4189.6 | 4809.5 | 5302.4 | 6546.2 | 8550.2 | 9652.3 | |

5.6 | 118.8 | 267.2 | 475.0 | 742.2 | 1068.8 | 1454.7 | 1900.0 | 2404.7 | 2968.8 | 3724.1 | 4275.1 | 4713.3 | 5818.9 | 7600.1 | 8579.8 | |

5 | 106.0 | 238.6 | 424.1 | 662.7 | 954.3 | 1298.9 | 1696.5 | 2147.1 | 2650.7 | 3325.1 | 3817.0 | 4208.3 | 5195.4 | 6785.8 | 7660.6 | |

4.5 | 95.4 | 214.7 | 381.7 | 596.4 | 858.8 | 1169.0 | 1526.8 | 1932.4 | 2385.6 | 2992.6 | 3435.3 | 3787.5 | 4675.9 | 6107.3 | 6894.5 | |

4 | 84.8 | 190.9 | 339.3 | 530.4 | 763.4 | 1039.1 | 1357.2 | 1717.7 | 2120.6 | 2660.0 | 3053.6 | 3366.6 | 4156.3 | 5428.7 | 6128.5 | |

3.55 | 75.3 | 169.4 | 301.1 | 470.5 | 677.5 | 922.2 | 1204.5 | 1524.4 | 1882.0 | 2360.8 | 2710.1 | 2987.9 | 3688.7 | 4817.9 | 5439.0 | |

3.15 | 66.8 | 150.3 | 267.2 | 417.5 | 601.2 | 818.3 | 1068.8 | 1352.7 | 1370.0 | 2094.8 | 2404.7 | 2651.2 | 3273.1 | 4275.1 | 4826.2 | |

2.5 | 53.0 | 119.3 | 212.1 | 331.3 | 477.1 | 649.4 | 848.2 | 1073.5 | 1325.4 | 1662.5 | 1908.5 | 2104.1 | 2597.7 | 3392.9 | 3830.3 | |

2 | 42.4 | 95.4 | 169.6 | 265.1 | 381.7 | 519.5 | 678.6 | 858.8 | 1060.3 | 1330.0 | 1526.8 | 1683.3 | 2078.2 | 2714.3 | 3064.2 | |

1.6 | 33.9 | 76.3 | 135.7 | 212.1 | 305.4 | 415.6 | 542.9 | 687.1 | 848.2 | 1064.0 | 1221.5 | 1346.6 | 1662.5 | 2171.5 | 2451.4 | |

1.25 | 26.5 | 59.6 | 106.0 | 165.7 | 238.6 | 324.7 | 424.1 | 536.8 | 662.7 | 831.3 | 954.3 | 1052.1 | 1298.9 | 1696.5 | 1915.1 | |

1 | 21.2 | 47.7 | 84.8 | 132.5 | 190.9 | 259.8 | 339.3 | 429.4 | 530.1 | 665.0 | 763.4 | 841.7 | 1039.1 | 1357.2 | 1532.1 | |

0.8 | 17.0 | 38.2 | 67.9 | 106.0 | 152.7 | 207.8 | 271.4 | 343.5 | 424.1 | 532.0 | 610.7 | 673.3 | 831.3 | 1085.7 | 1225.7 | |

0.63 | 13.4 | 30.1 | 53.4 | 83.5 | 120.2 | 163.7 | 213.8 | 270.5 | 334.0 | 419.0 | 480.9 | 530.2 | 654.6 | 855.0 | 965.2 | |

0.5 | 10.6 | 23.9 | 42.4 | 66.3 | 95.4 | 129.9 | 169.6 | 214.7 | 265.1 | 332.5 | 381.7 | 420.8 | 519.5 | 678.6 | 766.1 | |

Width of belt (mm) | 360 | 550 | 730 | 910 | 1100 | 1280 | 1460 | 1640 | 1820 | 2050 | 2190 | 2300 | 2550 | 2900 | 3100 | |

Diameter of tube (mm) | Φ100 | Φ150 | Φ200 | Φ250 | Φ300 | Φ350 | Φ400 | Φ450 | Φ500 | Φ560 | Φ600 | Φ630 | Φ700 | Φ800 | Φ850 | |

FAQ:

How to choose the diameter of the pipe?

In according to transported particle size and the transportation value, the diameter of the pipe can be chose.

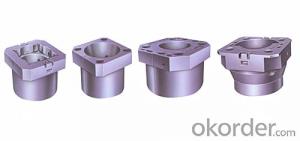

How to set the tubulation carrier roller

Generally, it adopts window type allocation. In line with various diameter of pipes, the regular hexagon carrier roller group is set on one side or both sides. Also, it can adopt octagon carrier roller group.

How to adjust the torsion of the adhesive belt?

Making the two carriers on one side of the carrier roller group forerake, it can be adjusted

Send your message to us

Circular Tube Belt Conveyor,Round Pipe Belt Conveyor,Continuous Transmission Equipment,Belt Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords