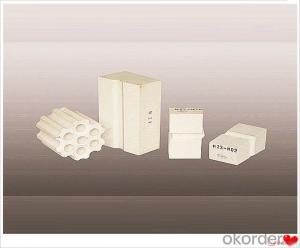

Fused Cast Chrome Magnesite Refractory Bricks for Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Magnesite Chrome Bricks

Index |

| AP (%)≤ | B.D | CCS | 0.2Mpa RUL(°C) ≥ | TSR | TE%1400 (°C) | TC | ||

MgO | SiO2 | Cr2O3 | ||||||||

MGe-12A | 73 | 1.5 | 12 | 17 | 3.15 | 45 | 1700 | 6 | 1.7 | |

MGe-12B | 70 | 2.5 | 12 | 17 | 3.10 | 45 | 1700 | 5 | ||

MGe-16A | 70 | 1.5 | 16 | 18 | 3.15 | 45 | 1700 | 6 | 1.6 | 2.6 |

MGe-16B | 68 | 2.5 | 16 | 18 | 3.05 | 35 | 1700 | 5 | ||

MGe-18A | 65 | 1.5 | 18 | 18 | 3.15 | 40 | 1700 | 6 | 3.0 | |

MGe-18B | 63 | 2.5 | 18 | 18 | 3.05 | 35 | 1700 | 5 | ||

MGe-20A | 60 | 2 | 20 | 18 | 3.15 | 40 | 1700 | 6 | - | - |

MGe-20B | 58 | 3 | 20 | 18 | 3.10 | 35 | 1700 | 6 | - | - |

MGe-22A | 58 | 2 | 22 | 18 | 3.15 | 40 | 1700 | 6 | - | - |

MGe-22B | 56 | 3 | 22 | 18 | 3.10 | 35 | 1700 | 6 | - | - |

General Information of Magnesite-Chrome Brick

l CMAX magnesite-chrome brick is made of high quality magnesia and chrome ore.

l CMAX direct-bonded magnesite-chrome brick is made of low impurity chrome ore and high purity magnesia and sintered at high temperature over 1700℃.

l CMAX semi-rebonded and rebonded magnesite-chrome bricks are made partially or fully of synthetic fused clinkers. Magnesite-chrome brick are shaped under high pressure and sintered at very high temperature.

Feature of Magnesite-Chrome Brick

Good high-temperature performance

High thermal shock resistance

Strong slag resistance

High mechanical strength

Application of Magnesite-Chrome Brick

Cement rotary kiln

Non-ferrous furnace

FAQ

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: How can the silica in zircon sand be removed during the smelting of zirconium corundum?

- How can the silica in zircon sand be removed during the smelting of zirconium corundum?The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.

- Q: What is brick power, half brick power and full brick power difference?

- Power module. Small size, high power. General use should order additional storage energy, heat dissipation, etc.. Dimensions such as brick, so called brick power supply. Half brick power supply is half the size of all brick power supply.

- Q: How are qualitative and qualitative refractories understood?

- Shaped refractory products, such as fired brick, fused brick (Rong Zhuzhuan), refractory insulation bricks, as well as experimental and industrial crucibles, utensils and other special products.

- Q: What is the face brick

- You should be talking about refractory bricksThe refractory brick brick. Referred to as refractory material has a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick, refractory insulating bricks (Rong Zhuzhuan);

- Q: Just what is in the furnace material?

- Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon aluminum

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Not always。Referred to as refractory brick. Refractory made from refractory clay or other refractory material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- The temporary pollution in the process of tiling should be cleaned in a timely manner with a damp cloth.

- Q: What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

- Q: Can the fire clay be reused?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

Send your message to us

Fused Cast Chrome Magnesite Refractory Bricks for Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords