Magnesite Chrome Refractory Electric Arc Furnace Bricks

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

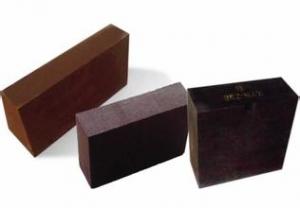

General Information of Magnesite Brick

CMAX magnesite brick is made of various grades of magnesia and is a kind of alkali resistance refractory brick.

Magnesia chrome brick is mainly made from sintered magnesia and chrome-oxide, by high pressure shaping and chrome-oxide,by high pressure shaping and high temperature firing.According to different requirements the contents of the Cr2O3 can be changed. The product has good specifications for the shock resistance and high temperature performance.

Feature of Magnesite Brick

Good high-temperature performance

High thermal shock resistance

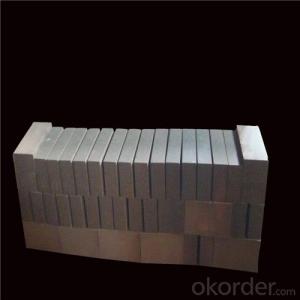

Image of Magnesite Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: What are the differences between magnesium chrome bricks, such as direct bonding, re bonding, semi bonding, CO sintering and chemical bonding? Hope expert advice..

- The process of firing magnesia chrome bricks is roughly the same as that of magnesia bricks. In order to eliminate the brick during firing, due to MgO and Cr2O3, Al2O3

- Q: Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.In addition, magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees.

- Q: Magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q: How many kinds of refractory bricks are there?

- Magnesia chrome brick: Hang kiln, used for firing zone, the disadvantage is the poor thermal shock resistance, plus six Cr price is highly toxic, the production and use of the national magnesia chrome brick is gradually reduced, the brick production unit as soon as possible to find alternatives.

- Q: Magnesium chrome brick price?

- In the brick factory products are now sold throughout the country and exported to the United States, South Africa, India, Germany, Canada, Ukraine, Japan and other countries, has been recognized and highly refractory materials in the world market.

- Q: What are the types of magnesia chrome bricks for industrial use?

- 1. burned magnesia chrome bricks 2. magnesia chrome bricks 3. semi bonded magnesia chrome brick and magnesia chrome brick generally is the three

- Q: What is a half combination of magnesia chrome bricks?

- Direct binding for magnesium magnesium rock stone or periclase spinel crystals, silicate phases were isolated in the grain asked. Half combined with thermal shock resistance than magnesia chrome brick direct bonded magnesia chrome brick, and about half combined with the characteristics of magnesia chrome brick, some physical and chemical indicators. I don't understand, I know there is a production of magnesia chrome brick factory technicians understand this, is known as gold refractory material factory.

- Q: With different capacitance magnesia brick brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: What are the main raw materials of magnesia chrome bricks?

- Magnesium alloys are alloys based on magnesium and other elements. Its characteristics are: small density (1.8g/cm3 magnesium alloy or so), high specific strength, high modulus of elasticity, good heat dissipation, good shock resistance, greater impact load capacity than aluminum alloy, good resistance to organic and alkaline corrosion. The main alloying elements are aluminum, zinc, manganese, cerium, thorium, and a small amount of zirconium or cadmium.

Send your message to us

Magnesite Chrome Refractory Electric Arc Furnace Bricks

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords