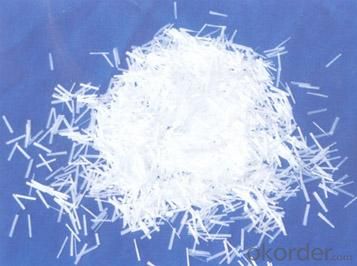

Chopped Strand Mat Fiberglass and Epoxy E Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

E-Glass Chopped Stands for thermoplastic are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

Product Features:

● Extremely low resin demand, delivering low viscosity to BMC paste

● High impact strength; High LOI rate

● High strand stiffness; Compatible with rubber

Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

● Special specification can be produce according to customer requirements.

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

FAQ:

1.Who will pay for the express cost ?

A: We can support you free samples ,but express cost will be paid by you .

2.How long is the delivery time?

A:within 10-15 days after receiving depos

- Q: Is fiberglass chopped strand suitable for acoustic insulation?

- No, fiberglass chopped strand is not suitable for acoustic insulation.

- Q: Aluminum paste carbon fiber glass fiber pulp slurry canoeing and what is the difference between what are the benefits of

- Carbon fiber (carbon, fibre) inorganic polymer fiber containing more than 90% carbon. Which contains more than 99% carbon fiber called graphite fiber. Carbon fiber axial strength and high modulus, no creep, fatigue resistance, between heat and electrical conductivity between the metal and non metal, low thermal expansion coefficient, good corrosion resistance, low fiber density, good permeability of X ray. But its impact resistance is bad, it is easy to damage, and it will oxidize under the action of strong acid. Metal carbonization, carburization and electrochemical corrosion will occur when combined with metal. Therefore, carbon fibers must be treated before they are used.

- Q: Is fiberglass chopped strand suitable for aerospace structural applications?

- Fiberglass chopped strand, a reinforcement material comprised of small strands of fiberglass, proves to be fitting for aerospace structural applications. Its remarkable features include a high strength-to-weight ratio, exceptional mechanical properties, and resistance to corrosion and chemicals. Consequently, this material is suitable for aerospace structural applications that necessitate lightweight yet sturdy materials. Moreover, fiberglass chopped strand's adaptability to intricate shapes enables its versatility in various aerospace components. Nevertheless, it is crucial to acknowledge that aerospace applications may entail distinct requirements and regulations. Therefore, thorough testing and certification must be undertaken to ascertain the appropriateness of fiberglass chopped strand for a specific aerospace structural application.

- Q: Is chopped glass fiber harmful to people?

- The general concept of glass is hard and brittle objects, but it is not suitable for timber structure as its thread, strength is greatly increased and is flexible, with resin to give it shape can finally become excellent timber structure. Glass fibers increase in strength as their diameter decreases.

- Q: Is fiberglass chopped strand water-resistant?

- Yes, fiberglass chopped strand is water-resistant.

- Q: Can fiberglass chopped strand be used in the production of marine vessels?

- Yes, fiberglass chopped strand can be used in the production of marine vessels. Fiberglass is a commonly used material in the marine industry due to its high strength-to-weight ratio, durability, and resistance to corrosion. Chopped strand mat, made from chopped fiberglass strands, is often used as a reinforcement material in boat hulls, decks, and other structural components. It can be easily molded, laminated, or infused with resin to create strong and lightweight composite structures. The use of fiberglass chopped strand in marine vessel production helps enhance the overall strength and performance of the boats while also providing resistance to water damage and degradation.

- Q: Can fiberglass chopped strand be used in the production of electrical insulation materials?

- Yes, fiberglass chopped strand can be used in the production of electrical insulation materials. Fiberglass is known for its excellent electrical insulation properties, making it an ideal choice for applications where electrical insulation is required. The chopped strand form of fiberglass consists of short fibers, which can be mixed with other materials and processed to create various insulation products such as tapes, sheets, and coatings. The chopped strand form allows for better dispersion and distribution of the fibers within the material, enhancing its electrical insulation capabilities. Additionally, fiberglass chopped strand is also resistant to high temperatures, chemicals, and moisture, further contributing to its suitability for electrical insulation applications.

- Q: Can fiberglass chopped strand be used for reinforcing wood materials?

- Fiberglass chopped strand is indeed suitable for reinforcing wood materials. This reinforcement material is crafted from fine glass strands that have been cut into shorter lengths. It is commonly employed in composite materials to bolster their strength and durability. When combined with wood materials, fiberglass chopped strand can significantly enhance the overall structural integrity and performance. The fiberglass strands impart additional strength and rigidity, thereby reducing the wood's susceptibility to warping, cracking, and splitting. They also minimize shrinkage and expansion caused by moisture, thereby improving the dimensional stability of the wood. To reinforce wood with fiberglass chopped strand, one typically mixes the strands with an adhesive or resin and applies the mixture onto the wood surface. This process creates a robust bond between the wood and the fiberglass, effectively reinforcing the material. Nevertheless, it is crucial to acknowledge that the effectiveness of fiberglass chopped strand in reinforcing wood materials may vary based on factors such as the type and quality of the wood, the application method, and the specific project requirements. It is advisable to consult a professional or adhere to manufacturer guidelines for optimal outcomes.

- Q: How does the color of the chopped strand affect its performance?

- There are several ways in which the performance of chopped strand can be influenced by its color. Primarily, the color can serve as an indicator of the type of resin or binder utilized to bind the strands together. Different resins possess distinct properties that can impact the strength, flexibility, and overall performance of the chopped strand. Furthermore, the color of the chopped strand can also have an effect on its adhesion properties. Certain colors may exhibit superior adhesion to specific materials or substrates, while others may not adhere as well. This can significantly impact the overall durability and strength of the final product. Additionally, the color of the chopped strand can also play a role in its resistance to UV degradation. Certain colors may possess a higher level of resistance, which is particularly crucial in applications where the material will be exposed to sunlight or outdoor conditions. This resistance helps to prevent the material from becoming brittle or discolored over time. Lastly, the color of the chopped strand can also contribute to its aesthetic appeal. In applications where appearance is of importance, such as in automotive or consumer products, the color of the chopped strand can greatly enhance the visual appeal of the finished product. To summarize, the color of chopped strand can impact its performance by influencing the type of resin used, adhesion properties, resistance to UV degradation, and aesthetic appeal. It is imperative to consider these factors when selecting chopped strand for a particular application in order to ensure optimal performance and desired results.

- Q: How does the fiber diameter affect the performance of fiberglass chopped strand?

- The fiber diameter plays a crucial role in determining the performance of fiberglass chopped strand. The diameter directly influences the mechanical properties, such as strength, stiffness, and impact resistance, of the chopped strand. A smaller fiber diameter generally leads to higher strength and stiffness. This is because a smaller diameter allows for a larger number of fibers to be incorporated into a given volume, resulting in more efficient load transfer and increased overall strength. Additionally, smaller diameter fibers tend to have fewer defects, such as voids or impurities, which can weaken the material. Moreover, a smaller diameter also enhances the interfacial bonding between the fibers and the matrix material, improving the overall composite performance. The increased surface area of the smaller fibers allows for better adhesion with the matrix, resulting in improved load transfer and enhanced mechanical properties. However, it is important to note that there is an optimal fiber diameter range for specific applications. If the fiber diameter becomes too small, it may become difficult to handle and process, leading to challenges in achieving uniform distribution and effective reinforcement within the matrix. On the other hand, if the fiber diameter becomes too large, it may result in a less efficient use of the material and reduced mechanical properties. In summary, the fiber diameter of fiberglass chopped strand significantly affects its performance. A smaller diameter generally improves strength, stiffness, and interfacial bonding, while also reducing defects. However, there is an optimal range to consider for each application to ensure ease of processing and optimal reinforcement.

Send your message to us

Chopped Strand Mat Fiberglass and Epoxy E Glass Fiber Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords