China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

T-type Joint Pipe (Push-on)

Standard:

ISO2531

Material:

ductile iron ggg50

Pressure:

PN10, PN16, PN25,PN40

Wall Thickness:

K9, K8, C25, C30, C40

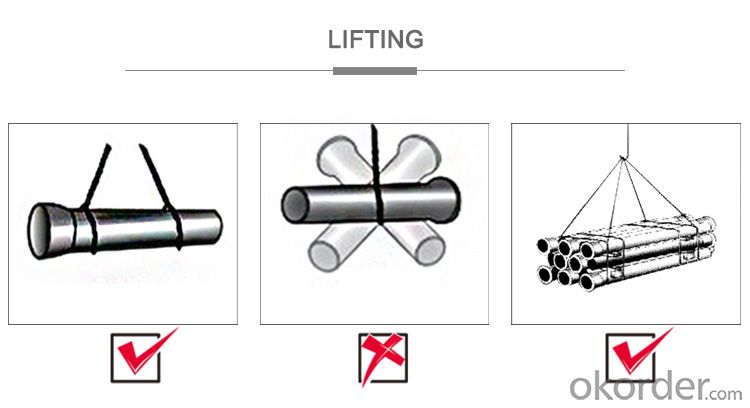

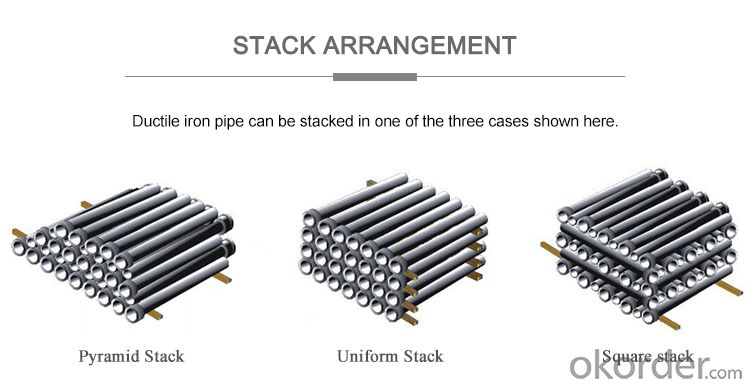

Packaging:

Bundle, in bulk

Yield (≥ MPa):

300MPa

Hardness:

≤230HB

Pull Strength:

≥420MPa

Processing Service:

Casting

Color:

Black, red, blue or as requested

Length:

6m, cut to 5.7m

China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

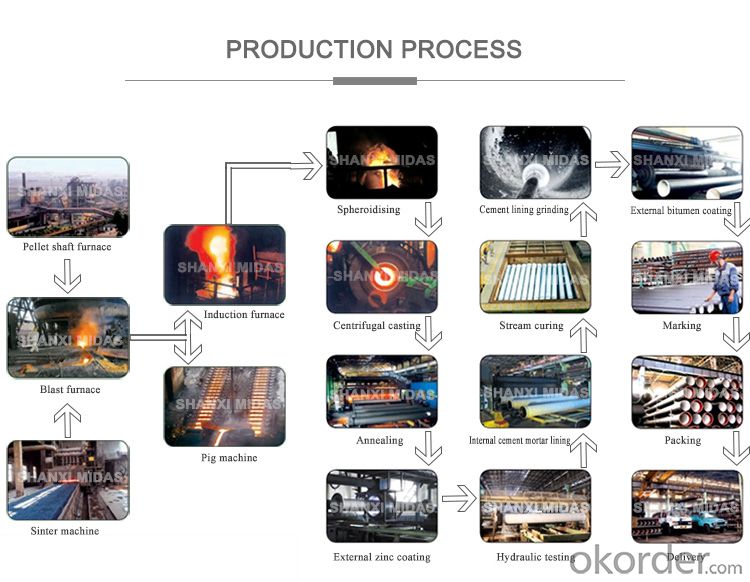

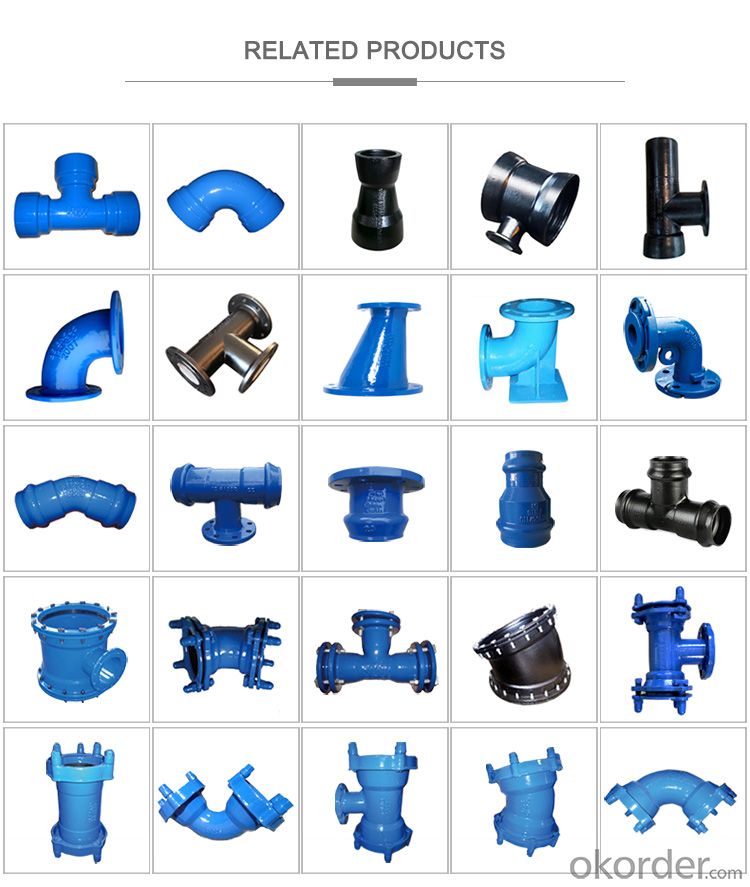

The T-type Joint Pipes (Push-on) produced by our company range from DN80mm to DN2600mm are flexibly jointed with sockets and spigots; they are the first choice in urban water pipe networks due to their convenient installation, strong seismic performances, seal ability and corrosion resistance.

Specifications

| Type | T-type Joint Pipe (Push-on) |

| Standard | ISO2531, EN545, EN598, etc |

| DN | DN80mm~DN2600mm |

| Material | Ductile Cast Iron GGG50 |

| Pressure | PN10, PN16, PN25,PN40 |

| Wall thickness | K9, K8, C25, C30, C40 |

| Length | 6m, cut to 5.7m |

| Application | Water supply project, drainage, irrigation, water pipeline system. |

| Internal Coating | a). Portland cement mortar lining |

| b). Sulphate Resistant cement mortar lining | |

| c). High-Aluminum cement mortar lining | |

| d). Fusion bonded epoxy coating | |

| e). Liquid epoxy painting | |

| f). Black bitumen painting | |

| External Coating | a). zinc+bitumen(70microns) painting |

| b). Fusion bonded epoxy coating | |

| c). Zinc-aluminum alloy +liquid epoxy painting | |

| Package | Bundles, in bulk |

| Note | The coating can also be accordance with customers' requirements. |

Product Images

- Q: What new technologies are there for the installation of ductile iron pipes?

- Because the new flexible interface mechanism of cast iron drainage pipe pipe in the development of China's relatively short history, compared with other drainage pipes, people know little of the present, with some experience of the author in the construction, the application of the performance, characteristics and engineering, to do some simple introduction.

- Q: Are ductile iron pipes suitable for installation in areas with high groundwater salinity?

- Areas with high groundwater salinity are generally suitable for the installation of ductile iron pipes. Ductile iron is renowned for its resistance to corrosion, making it a favored choice for various applications, such as water and wastewater systems. High groundwater salinity refers to the increased presence of dissolved salts in the water. Although this can potentially cause corrosion in certain materials, ductile iron pipes are specifically engineered to withstand such conditions. These pipes are equipped with a protective lining, usually composed of cement mortar or polyurethane, which acts as a barrier between the pipe and its surroundings, including highly saline water. The lining serves to prevent any corrosive effects of the high groundwater salinity on the iron pipe, ensuring its long-lasting durability and reliability. Furthermore, ductile iron pipes possess a high tensile strength, enabling them to endure external loads and pressure, even in demanding environments. It is important to acknowledge that the suitability of ductile iron pipes for areas with high groundwater salinity can also be influenced by factors such as the specific levels of salinity, the presence of other corrosive agents, and the overall design and installation practices. Therefore, it is advisable to consult experts or engineers who are familiar with the local conditions in order to determine the most appropriate materials and precautions for specific installation projects.

- Q: What are the common methods for cutting ductile iron pipes?

- There are several common methods for cutting ductile iron pipes, depending on the specific requirements and tools available. 1. Hand Saw: A hand saw with a carbide-tipped blade is commonly used for cutting smaller diameter ductile iron pipes. This method requires physical effort and may be time-consuming. 2. Reciprocating Saw: A reciprocating saw with a diamond or carbide abrasive blade is a more efficient option for cutting ductile iron pipes. This power tool allows for faster cutting and requires less physical effort. 3. Cut-Off Saw: A cut-off saw, also known as a chop saw or disc cutter, equipped with a diamond or abrasive blade is a popular method for cutting ductile iron pipes. This power tool provides precise and fast cuts, making it suitable for both small and large diameter pipes. 4. Band Saw: A band saw with a bi-metal or carbide-tipped blade is commonly used for cutting larger diameter ductile iron pipes. This method allows for clean and precise cuts, but it may require specialized equipment and expertise. 5. Grinding Wheel: In some cases, a grinding wheel with a diamond or abrasive disc can be used to cut ductile iron pipes. This method is suitable for smaller diameter pipes or when other cutting tools are not available. It is important to note that regardless of the method used, proper safety precautions should always be followed, including wearing appropriate protective gear and using clamps or vices to secure the pipe during cutting. Additionally, it is recommended to consult with professionals or manufacturers' guidelines for specific recommendations on cutting ductile iron pipes.

- Q: What's the function of the cement mortar lining of ductile iron pipes?

- You may easily say that this statement is vague and there is no evidence that other manufacturers often do so when promoting other types of lining. However, in order to prove the truth of the above view, we have compiled sufficient examples to demonstrate the reliability of each of these statements from a scientific and logical point of view.We have stated each of these fields and other embedded systems as specious statements. There is only a reasonable conclusion that the cement mortar lining (CML) provides excellent protection for ductile iron pipes and steel tubes.Ductile iron pipe and steel pipe CML CML produces a synergistic effect of the incomparable.

- Q: Are ductile iron pipes suitable for wastewater systems?

- Yes, ductile iron pipes are suitable for wastewater systems. They have high strength, durability, and corrosion resistance, making them ideal for handling the demanding conditions and harsh environment typically found in wastewater systems. Additionally, ductile iron pipes have good joint integrity, which ensures leak-free connections and minimizes maintenance requirements in wastewater applications.

- Q: How do ductile iron pipes handle internal scale buildup?

- Ductile iron pipes are known for their excellent resistance to internal scale buildup. The material used in ductile iron pipes is highly resistant to corrosion, which helps prevent the formation of scale deposits. Additionally, the smooth internal surface of these pipes minimizes the chances of scale adherence. In the rare event that scale does start to form, ductile iron pipes handle it quite well. The inherent strength and durability of ductile iron allow it to withstand the pressure exerted by the scale buildup. The pipes can continue to function efficiently even with some internal scaling, ensuring a reliable water flow. However, it is important to note that regular maintenance and periodic cleaning are still necessary to prevent excessive scale accumulation and ensure optimal pipe performance. This can be done through various methods such as mechanical cleaning, chemical treatments, or high-pressure water jetting. Proper maintenance practices can help prolong the lifespan of ductile iron pipes and minimize any potential issues related to internal scale buildup.

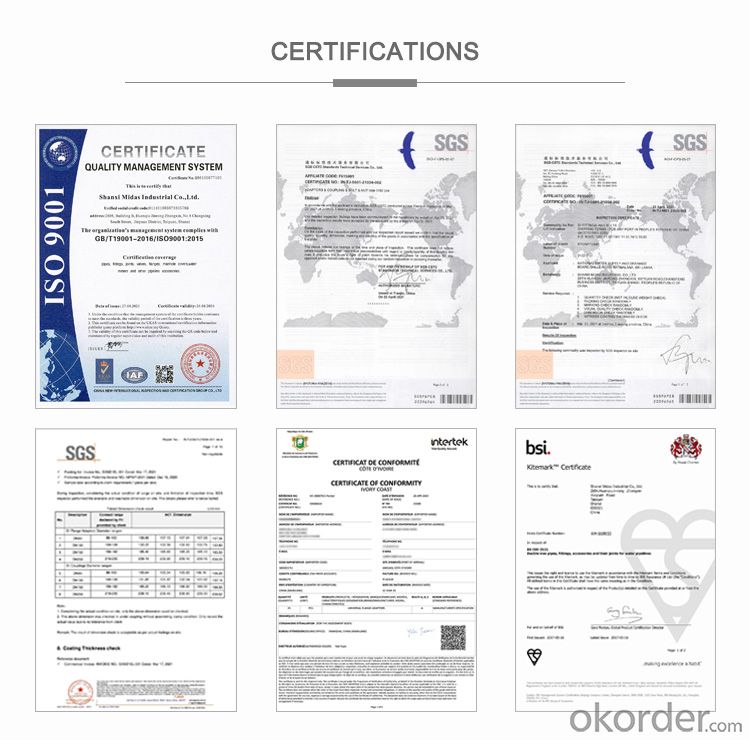

- Q: How are ductile iron pipes tested for quality assurance?

- To guarantee the quality and adherence to industry standards of ductile iron pipes, a variety of testing procedures are carried out. These tests evaluate both the raw materials and the finished products, aiming to ensure the pipes' durability, strength, and overall reliability. The first step involves analyzing the chemical composition of the raw materials used in the manufacturing process. This analysis verifies that the iron, carbon, and other elements fall within the specified range, as different compositions can impact the pipes' strength and resistance to corrosion. Next, mechanical tests assess the pipes' strength and ductility. Tensile tests determine properties like ultimate tensile strength, yield strength, and elongation, which help assess the pipes' ability to withstand external pressure and bending forces. Moreover, impact tests measure the pipe's ability to resist sudden loading or impact. By evaluating the energy absorbed by the pipes under high impact force, these tests ensure that the pipes can endure accidental impacts during installation or operation. Another pivotal test is the hydrostatic pressure test, which examines the pipes' capacity to withstand internal pressure. By subjecting the pipes to a specific pressure for a designated duration while filled with water, this test ensures their capability to handle expected operating pressures without any leakage or failure. Furthermore, dimensional and visual inspections are conducted to verify that the pipes meet the required specifications. These inspections involve checking the outer diameter, length, wall thickness, and overall appearance for any defects, such as cracks, voids, or irregularities. Lastly, corrosion resistance tests evaluate the pipes' ability to resist corrosion when exposed to different environments or fluids. These tests help determine the pipes' expected lifespan and their suitability for various applications. In conclusion, these quality assurance tests are vital in ensuring that ductile iron pipes adhere to the necessary standards and deliver dependable, long-lasting performance in diverse infrastructure projects.

- Q: Can ductile iron pipes be used for both water and sewer applications?

- Yes, ductile iron pipes can be used for both water and sewer applications. Ductile iron pipes have excellent strength, durability, and corrosion resistance, making them suitable for carrying both water and sewage. They are commonly used in various water supply and wastewater systems due to their ability to withstand high pressure and resist chemical reactions caused by sewage.

- Q: Can ductile iron pipes be used for river crossings?

- Yes, ductile iron pipes can be used for river crossings. Ductile iron is a strong and durable material that is capable of withstanding the pressure and stress of being buried and crossed by a river. It is commonly used for various applications, including water and sewage systems, and has been proven to be reliable for river crossings. However, it is important to consider other factors such as the depth of the river, the size and weight of the pipes, and the installation process to ensure the proper design and installation of the ductile iron pipes for river crossings.

- Q: Usage of ductile iron pipe expander

- Usage of ductile iron pipe expander:1, the expansion device should check its type, specification and piping configuration before installation, must comply with the design requirements.2, the expansion of the inner sleeve should be noted that the direction of the inner sleeve is consistent with the direction of the medium flow. The hinge rotation plane of the hinge type telescopic device should be consistent with the displacement rotation plane.3, the need for "cold tight" expansion device, pre deformation of the auxiliary components should be installed in the pipeline before they can be removed.4, it is strictly prohibited to use telescopic deformation method to adjust the installation of the pipe, so as not to affect the normal function of the telescopic device, reduce the service life and increase the piping, equipment and supporting components of the load.5 、 during installation, welding slag is not allowed to splash to the surface of wave shell, and the wave shell is not allowed to suffer other mechanical damage.6, pipe installation is completed, should be removed as soon as the wave expansion device used for installation and transportation of yellow auxiliary positioning components and fasteners, and according to the design requirements will be transferred to the specified position limiting device, the pipe system has the ability to compensate fully in the environmental conditions.

Send your message to us

China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords