Glass Wool Board 30kg/m3 - China Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Glasswool Board Description:

Glasswool board is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; temperature keeping of computer rooms, refrigerator; denoise of power plants and pump rooms; adjustment of Hi-fi etc.

This special cell structure means that the sheet doe’s not conduct heat. When you lay XPS boards as an underlay any heat from your room or floor will be reflected back towards the floor surface. As you will not be wasting heat through your floor you will utilize your energy in an effective manner and thereby lower your energy consumption and carbon footprint.

2. Main Features:

1. Excellent thermal insulation

2. High compressive strength of excellence

3. High-quality water-repellent, moisture resistance

4. Energy saving and environmental protection

5. Excellent heat preservation and insulation

3. Scope of application:

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc

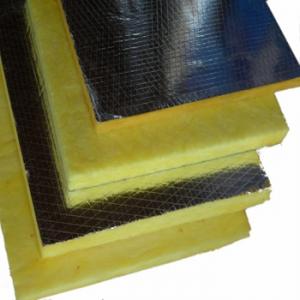

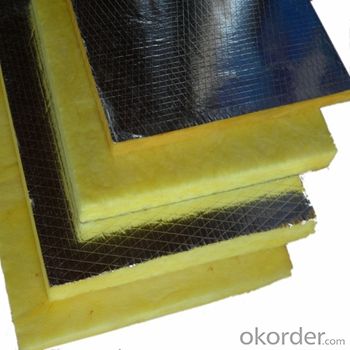

4. Glasswool Board Images

5. Glasswool Board Specification ool. Glasswool with alum foil

density(kg/m3) | width(mm) | thickness(mm) | length(m) | packing/roll Vacuum package | |

10-48 | 1200 | 25-150 | 10-30m | 2roll | |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

10-48 | 1200 | 25-150 | 10-30m | 1roll | two-roll overlapping |

6. FAQ

(1) How about your company?

A world class manufacturer & supplier of glasswool and is one of the large scale professional investment glasswool bases in China. Annually more than 1000 containers of glasswool are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

The user should take test and do trial application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q: Does rock wool refer to the glass wool?

- Rock wool is not glass wool, ~ ~ ~ two kinds of products, appearance, price, performance are different, have obvious difference.

- Q: what's the price of high temperature resistance glass wool?

- glass wool is the coiled material adapt to the material laying in a large area. except for the temperature preservation and thermal insulation, it has excellent shock absorption and sound absorption, and having good effect especially in the absorption of shock and noise in low and medium frequency and other types of shocks, which is good for the reduction of noise and work environment improvement. This material may also be needed in the construction of any cut, mainly used for building interior, muffler systems, transportation, refrigeration equipment, household appliances damping, sound absorption, noise reduction, and the effect is very good. the glass wool has pasted aluminium foil , and it has a strong thermal radiation, and is the best lining material of high temperature workshops, control room, inner wall of machinery room and flat top compartment. the price of high temperature resistance glass wool is around 300 yuan.

- Q: Polyester and glass wool, which is better, and why?

- The first one is better, it has good flexibility.

- Q: How about the quoted price of asphalt glass wool felt?

- There are specifications of size. Asphalt glass wool felt one square meter costs about 2 to 3 dollars on average. It may be slightly more expensive if buy a single one.

- Q: Which thermal insulation materials are the best for air-conditioners? Is it rubber and plastic, PEF or glass wool?

- Rubber and plastic is a better choice for conduits.

- Q: Glass wool 159 * 70 What does it mean

- 70 km diameter 159mm.

- Q: what is the raw materials producing glass wool insulation materials?

- simply put. It is a kind of glass, just like using white sugar to make cotton candy.

- Q: What is the difference between glass wool and rock wool insulation board insulation board ?

- Low density than glass wool rock wool, low shot content, low thermal conductivity, long service life, high tenacity fiber, rock wool, but the maximum use of high temperature up to about 600 degrees Celsius, the glass wool is only about 260 degrees Celsius. Glass wool and rock wool insulation board insulation board product differ in their application . The former one is used in areas where the temperature is below 200 degrees Celsius, such as general buildings and low-temperature pipes while the latter one is used in areas where the temperature is 500 degree Celsius, such as high temperature thermal pipe or eletrical equipments insualtion.

- Q: Does anyone know about the specifications of formaldehyde-free glass?wool?boards?

- The specifications of formaldehyde-free glass wool board are: 32KG / 50MM, 48KG / 50MM, 80KG / 50MM, 96KG / 25MM, 80KG / 25MM, these are all commonly used now. Hebei kaina Insulation Materials Co., Ltd. is good, which is a large-scale mainstay enterprise of research and development, production and sale of fireproofing and thermal insulation materials. It involves in thermal insulation materials of rock wool, glass wool, phenolic, aluminum silicate, design and construction as well as many other fields. Company products are widely used in many areas and industries around the country for their good quality and cheap price. Hebei kaina Insulation Materials Co., Ltd is located in Dacheng Hebei, the country's largest base of green thermal insulation construction materials. The main products include rock wool products, glass wool products, aluminum silicate products, rubber and plastic products, foam glass thermal insulation board, elevator shaft sound absorption boards.

Send your message to us

Glass Wool Board 30kg/m3 - China Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches