China factory galvanized steel coil hot dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

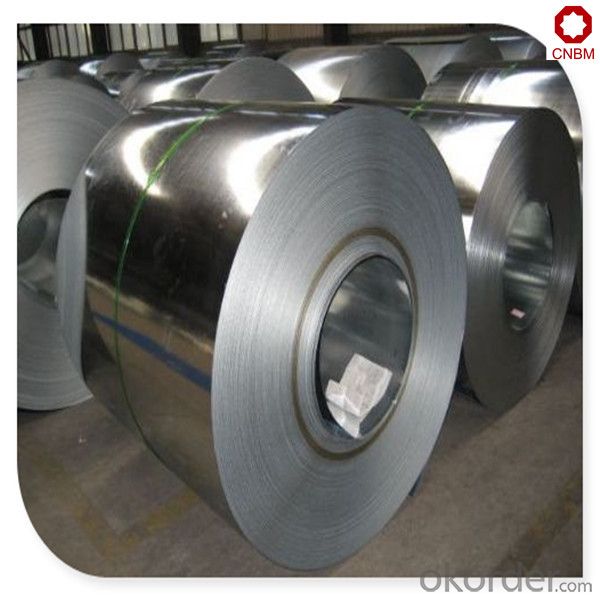

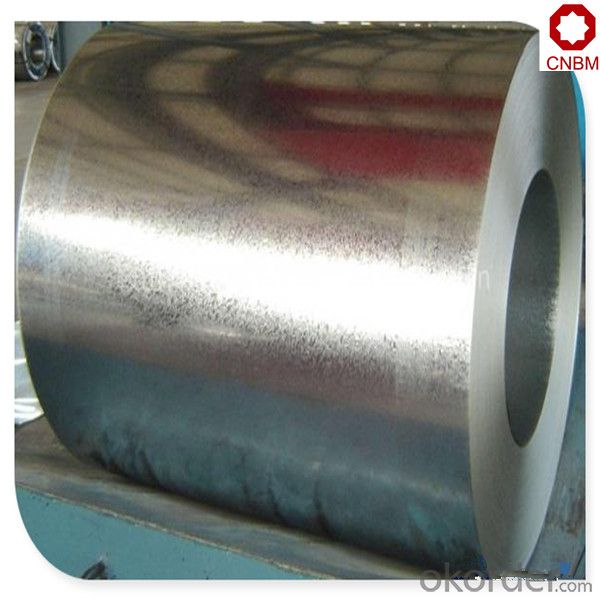

Pictures for stainless steel coil :

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- steel wire has to be silver soldered, or brazed ,or spot welded, you can not solder it, with reg solder or a soldering iron, use a small torch, like a pencil torch,

- Q: What are the challenges in coil slitting for thin gauge materials?

- Some of the challenges in coil slitting for thin gauge materials include maintaining precise tolerances, avoiding material deformation or buckling during the slitting process, and ensuring consistent edge quality. Additionally, handling and feeding thin gauge materials can be more delicate, as they are more prone to damage or distortion. Proper tension control and alignment are crucial to prevent issues like edge wave or camber, which can affect the overall quality of the slit coils.

- Q: What are steel coils used for?

- Steel coils are used in a wide range of industries and applications, including manufacturing, construction, automotive, and appliances. They are commonly used in the production of various metal products such as pipes, tubes, sheets, and wires. Steel coils provide strength, durability, and versatility, making them essential in many industrial processes.

- Q: Are steel pokemon weak against any attacks? If so, what types? (like water, grass, etc.)

- Thier weak aginst Fire type pokemon.

- Q: is a 1962 steel penny worth anything?

- I don't think they made steel pennies in 1962, did they?

- Q: How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q: How are steel coils inspected for formability?

- Steel coils are inspected for formability through a combination of visual inspection, physical testing, and advanced technologies such as laser scanning and digital image correlation. These methods assess the coil's surface condition, dimensional accuracy, and mechanical properties to ensure it meets the required standards for various forming processes.

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- its used in lots of things (cutlery, bridges, engines), and riotinto have made a lot of money from it. and it's an alloy of iron with a bit of carbon in.

- Q: How are steel coils used in the manufacturing of tubes?

- Steel coils are used in the manufacturing of tubes by being unwound and fed through a tube mill where they are shaped and welded together to form seamless or welded tubes.

- Q: should I shoot Herters .308 steel cased ammo in my Remington 7400.and why shouldn't I?

- Won't hurt anything, but do be aware, if you're plinking with it, that FMJ (and maybe even steel core), cheap ammo offers more chance of penetration and ricochet so be sure you've got a good back-stop so you know where those rounds wind up.

Send your message to us

China factory galvanized steel coil hot dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords