China 3003 Coated Aluminum Coil - Yellow Coil Coating Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Yellow Coil Coating Aluminium Coils for ACP Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Yellow Coil Coating Aluminium Coils for ACP

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

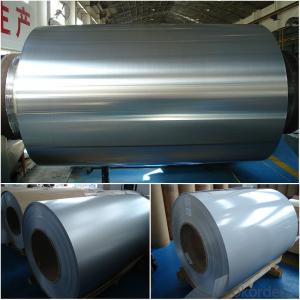

3. Yellow Coil Coating Aluminium Coils for ACP Images

4. Yellow Coil Coating Aluminium Coils for ACP Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Yellow Coil Coating Aluminium Coils for ACP

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Can aluminum coils be welded or joined?

- Aluminum coils have the capability to be welded or joined. Aluminum, being a highly weldable metal, can be easily joined through the utilization of different welding techniques. TIG welding, MIG welding, and resistance welding are the most commonly employed methods for welding aluminum coils. TIG welding is a precise and adaptable technique that employs a non-consumable tungsten electrode to generate the arc. This method is extensively utilized in welding aluminum coils due to its ability to offer exceptional control over the welding process, resulting in welds of high quality and strength. On the other hand, MIG welding employs a consumable wire electrode and a shielding gas to safeguard the weld zone from atmospheric contamination. This technique is faster compared to TIG welding and is often favored for larger production runs. Resistance welding is yet another prevalent method employed for joining aluminum coils. It involves the passage of an electric current through the overlapping metal surfaces to generate heat and pressure, thereby creating a robust weld joint. This technique is commonly used in industries that require high-speed production. It is important to note that welding aluminum coils necessitates specific techniques and considerations due to the distinctive properties of the metal. Aluminum possesses a lower melting point and higher thermal conductivity than other metals, which can make the welding process more challenging. Proper cleaning, preheating, and the selection of suitable filler materials are crucial in achieving successful welds. To summarize, aluminum coils can be welded or joined using various techniques such as TIG welding, MIG welding, and resistance welding. However, it is imperative to adhere to proper procedures and take into account the specific properties of aluminum to ensure the creation of strong and dependable welds.

- Q: This question asks for a method to compact an aluminum coil by folding it.

- <p>To fold an aluminum coil for compactness, first ensure the coil is free of sharp edges or damage. Use gloves for safety. Start by laying the coil flat. Measure and mark the desired folded length. Begin folding the coil by bringing one end towards the center, aligning the edges neatly. Continue folding back and forth, ensuring each fold is tight and even. Use a rubber mallet or similar tool to secure the folds, if necessary. For larger coils, consider using a mechanical folder or press to apply even pressure. Always work in a well-ventilated area and follow safety guidelines to prevent injury.</p>

- Q: Is it possible to utilize a punching machine to create holes in steel coils for decorative purposes?

- <p>Yes, you can use a punching machine to punch holes in steel coils for decoration purposes. Punching machines are designed to create precise holes in various materials, including steel. For steel coils, ensure the machine is capable of handling the thickness and hardness of the steel. It's important to select the right punch and die material, and consider the coil's strength and ductility. Always follow safety guidelines and machine specifications to prevent damage or injury.</p>

- Q: How are aluminum coils used in the production of HVAC components?

- Aluminum coils are used in the production of HVAC components as they serve as the heat transfer medium. These coils help in the efficient exchange of heat between the refrigerant and the surrounding air, facilitating the cooling or heating process. The aluminum material is lightweight, durable, and has excellent thermal conductivity, making it ideal for this purpose.

- Q: What are the common surface defects or issues in aluminum coils?

- Some common surface defects or issues in aluminum coils include scratches, dents, stains, oxidation, and uneven coatings.

- Q: How much is aluminum-plastic panel with the 0.155mm thick aluminum per ton?

- The price is around 17000 yuan per ton, but you need to take the surface effect into account

- Q: Are aluminum coils suitable for low-maintenance roofing applications?

- Yes, aluminum coils are suitable for low-maintenance roofing applications. Aluminum is known for its durability, longevity, and resistance to corrosion, making it an ideal material for roofing. Aluminum coils are lightweight yet strong, providing excellent structural integrity to withstand various weather conditions. Additionally, aluminum is a low-maintenance material as it does not rust or require regular painting. This means that homeowners or building managers can save time and money on maintenance tasks such as repainting or replacing rusted parts. Overall, aluminum coils are an excellent choice for low-maintenance roofing applications.

- Q: Are aluminum coils suitable for automotive applications?

- Yes, aluminum coils are suitable for automotive applications. Aluminum is a lightweight material that offers several advantages for automotive use. It provides excellent thermal conductivity, which allows for efficient heat transfer and cooling within the vehicle. Additionally, aluminum is corrosion-resistant, making it ideal for automotive applications where exposure to moisture and various weather conditions is common. Moreover, aluminum coils have high strength-to-weight ratio, meaning they provide strength and durability while keeping the weight of the vehicle low. This is particularly beneficial for improving fuel efficiency and reducing emissions. Furthermore, aluminum coils can be easily formed and shaped into various automotive components, such as heat exchangers, radiators, condensers, and evaporators, making them versatile and suitable for a wide range of automotive applications.

- Q: Can aluminum coils be used in the production of solar reflectors?

- Yes, aluminum coils can be used in the production of solar reflectors. Aluminum is a common choice due to its high reflectivity and durability, making it suitable for reflecting and directing sunlight efficiently in solar energy systems.

- Q: How do aluminum coils contribute to noise reduction in buildings?

- The unique properties and installation techniques of aluminum coils can contribute to noise reduction in buildings. To begin, aluminum's density and ability to absorb and dampen sound waves make it a highly efficient sound insulator. When used as coil insulation, aluminum effectively blocks and reduces airborne noise transmission, minimizing the impact of external sounds on the building's interior. In addition to aluminum's inherent sound insulation properties, the installation of aluminum coils in buildings can further enhance noise reduction. By strategically placing the coils in areas where noise transmission is likely to occur, such as HVAC systems and ductwork, potential gaps or openings that could allow sound to travel are eliminated when tightly sealed with aluminum coils. Furthermore, aluminum coils act as a barrier to vibration and resonance noises. They can be installed around mechanical equipment or structural elements prone to vibration, effectively dampening these vibrations and preventing them from propagating throughout the building. This is particularly important in reducing low-frequency noises, which are typically more difficult to control and can significantly impact the comfort and productivity of occupants. Moreover, aluminum coils offer durability and longevity, ensuring their effectiveness in noise reduction over a long period. They are resistant to corrosion, moisture, and other environmental factors, maintaining their sound-insulating properties and preventing sound leakage. In conclusion, by combining the sound insulation properties of aluminum with strategic installation techniques, such as sealing gaps and dampening vibrations, aluminum coils play a vital role in reducing noise transmission in buildings. Their ability to absorb, block, and dampen sound waves makes them an effective solution for creating quieter and more comfortable indoor environments.

Send your message to us

China 3003 Coated Aluminum Coil - Yellow Coil Coating Aluminium Coils for ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords