Cheap RP HD HP UHP Grade Graphite Electrodes for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. The item here is HD grade graphite electrodes, Bulk Density: ≥1.58g/cm3, Resistivity: ≤8.5ohm. Diameter is 75-600mm, length is 1800±100mm. We welcome your inquiry!

2.Main Features of the Graphite Electrode

(1) Pure carbon content

(2) Competitive price

(3) High density ≥1.58g/cm3 and low resistivity ≤8.5ohm

(4) Large quantity in stock, about 2500MT.

(5) RP HP UHP grade for your choice

3.Graphite Electrode Images

More products for your reference:

Packaging: Wooden Pallets with Steel Strips

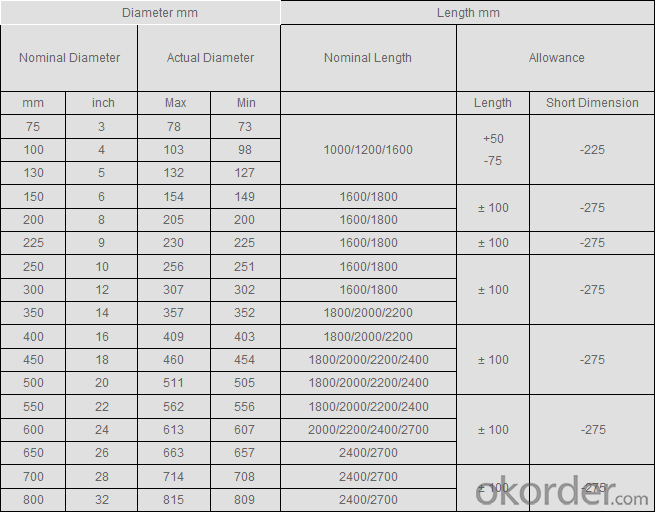

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 5 MT.

(3) Payment term

30% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q: Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- Silicon carbide graphite is very famous for its high hardness and wear resistance. It is generally used in high wear resistance machinery industry and high wear resistant sealing industry.

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- Ultra high power graphite electrode. A graphite electrode that allows current densities greater than 25A/ cm 2 is allowed. Mainly used in ultra high power steelmaking arc furnace

- Q: Which department in the steel plant needs graphite in large quantities?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: Classification of graphite electrodes

- Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: Graphite graphite graphite graphite electrode what is the use?

- Natural graphite electrode is the main raw material with graphite, high purity flake graphite powder or high carbon flake graphite powder as raw material, because carbon or graphite powder purity is high, the effect of conductive graphite powder is better in smelting alloy steel, iron alloy, electrode graphite powder as raw material. The electrode produced, then the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to 2000 degrees Celsius, so as to achieve the purpose of melting or reaction.

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- The problem is this. I have done the test of electrolytic copper sulfate, and the anode produced the same phenomenon. Finally, the chemistry teacher told me that it was because the graphite was broken in the process of electrolysis

- Q: I remember the more lively metal, the electron?

- Metal ion is more inert electron, graphite electrode for electrolytic salt solution containing the same amount of substance A and C two metals, C first precipitated, so C is copper. In a dilute sulfuric acid with H2 precipitation, certainly not a copper. The more active metal betatopic ability is strong, have the corresponding ion electronic ability weaker. First metal ions corresponding to metal electrons are not active.

- Q: Graphitized anode, cathode and graphite electrode, respectively How can one differentiate and use differently?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages

Send your message to us

Cheap RP HD HP UHP Grade Graphite Electrodes for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches